- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 22, 2024 14:43 Back to list

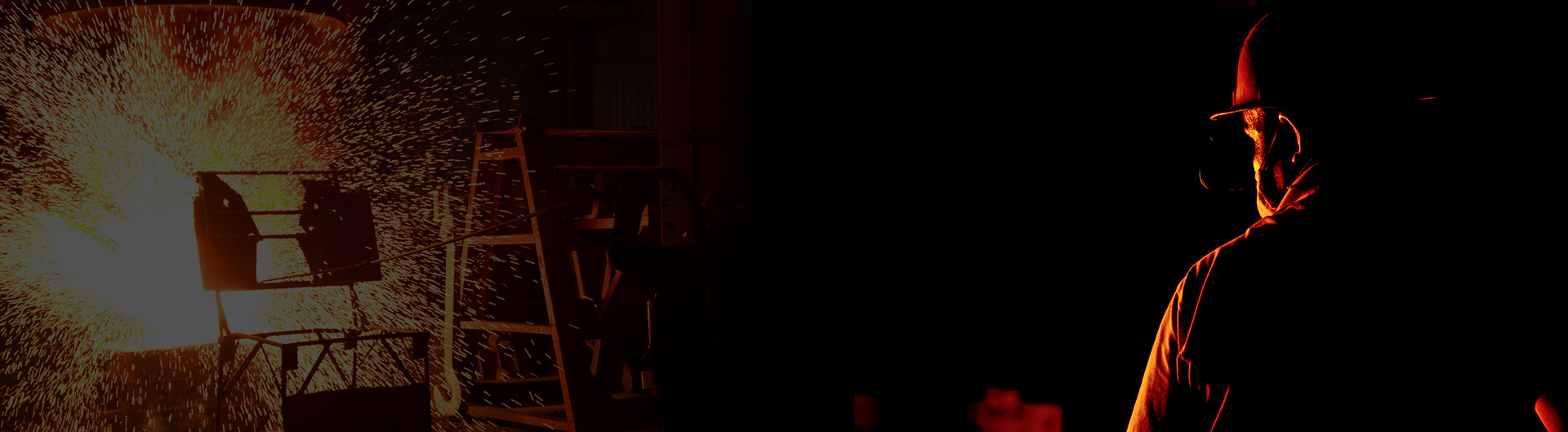

foundry casting

The Art and Craft of Foundry Casting

Foundry casting is an age-old technique that has evolved significantly over the centuries, playing a pivotal role in various industries, from automotive to aerospace and even art. This process involves pouring molten metal into a mold to create intricate shapes and objects, showcasing a remarkable blend of science, engineering, and artistry. In this article, we will explore the fundamentals of foundry casting, its various methods, applications, and the future of this essential manufacturing process.

The Basics of Foundry Casting

At its core, foundry casting begins with the creation of a mold that defines the shape of the final product. Molds can be made from various materials, including sand, metal, and ceramic, depending on the casting method and the properties required in the finished piece. The primary steps in the casting process involve pattern making, mold preparation, pouring, and finishing.

1. Pattern Making This step involves creating a replica of the object to be cast, typically from wood, metal, or plastic. The pattern must account for factors such as shrinkage and warping that can occur when the metal cools.

2. Mold Preparation The pattern is placed in a mold box, where a suitable material (like sand or a ceramic slurry) is packed around it to create a cavity. Once the mold material hardens, the pattern is removed, leaving a hollow space that mirrors the desired shape.

3. Pouring Molten metal, usually heated to a precise temperature to ensure fluidity, is then poured into the mold cavity. The casting must be done swiftly and carefully to avoid defects such as air pockets, which can weaken the structure.

4. Finishing After the metal has cooled and solidified, the mold is broken away to reveal the cast object. Depending on the application, additional finishing processes such as machining, grinding, and painting may be necessary to achieve the final specifications and aesthetic quality.

Various Methods of Casting

Foundry casting encompasses several methods, each with its unique advantages and applications

. Some of the most common methods includefoundry casting

- Sand Casting The most popular casting method, sand casting uses sand as the mold material. It's versatile, cost-effective, and ideal for producing large items with complex shapes, making it widely used in automotive and agricultural machinery.

- Investment Casting Also known as lost-wax casting, this precision method is used to create intricate and high-detail components. A wax pattern is coated with a ceramic material, which is then heated to remove the wax, leaving a mold for molten metal. This method is invaluable in aerospace and medical device manufacturing.

- Die Casting In die casting, molten metal is injected into a metal mold under high pressure. This technique is suitable for mass production of small, precise parts, typically made with non-ferrous metals.

- Continuous Casting Ideal for producing long sections of material, continuous casting is a method where molten metal is continuously poured into a mold. This technique is commonly used in the production of steel billets and slabs.

Applications of Foundry Casting

Foundry casting is vital to countless industries. In the automotive sector, it is used to create engine blocks, cylinder heads, and transmission cases. In aerospace, precision cast parts are crucial for ensuring safety and efficiency in flight. Additionally, foundry casting also finds applications in the manufacturing of household items, artistic sculptures, and even historical artifacts.

The Future of Foundry Casting

As technology advances, so does the foundry casting industry. Innovations such as 3D printing are revolutionizing mold-making processes, allowing for faster and more cost-effective production of complex designs. Furthermore, sustainable practices are becoming increasingly important, with many foundries seeking to reduce waste and energy consumption through recycled materials and improved techniques.

In conclusion, foundry casting is a foundational process in manufacturing that continues to evolve. Its combination of traditional techniques and modern innovations allows for the creation of high-quality, intricate parts that are essential across various industries. As we move forward, the role of foundry casting will only enhance, shaping the future of manufacturing and design.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025