- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 10, 2024 22:06 Back to list

FRC Concrete Pipe Mold and Pallet Manufacturing Facilities Overview

FRC Concrete Pipe Mold Pallet Factories An Overview

The construction and infrastructure industries continue to evolve, necessitating the use of innovative materials and technologies. One of the crucial components in constructing durable and efficient drainage systems is the use of Fiber Reinforced Concrete (FRC) pipes. To manufacture these high-quality pipes, a reliable and efficient production process is essential. This is where FRC concrete pipe mold pallet factories come into play.

Understanding FRC and Its Applications

Fiber Reinforced Concrete is a composite material that incorporates various types of fibers, such as steel, glass, or synthetic fibers, into the concrete mix. This reinforcement enhances the material’s overall performance, including its tensile strength, ductility, and resistance to cracking. FRC is widely used in constructing pipes for drainage, sewage systems, and other infrastructure applications, as it provides durability and long service life, reducing the need for frequent maintenance and replacement.

The Role of Mold Pallets in Production

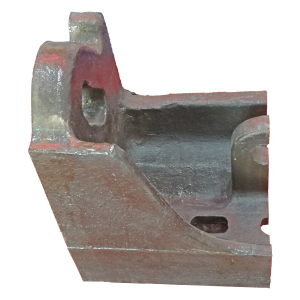

In the production of FRC pipes, mold pallets are pivotal equipment. These pallets serve as the base onto which concrete is poured to form the pipe shape. The quality and design of the mold pallets significantly influence the final product's characteristics. Factors such as surface finish, dimensional accuracy, and durability are all governed by the mold's construction.

Mold pallets must be designed to withstand the heavy loads and vibrations during the concrete curing process. They often incorporate features like smooth finishes to facilitate easy removal of the cured pipes and ensure accurate dimensions. Furthermore, advanced manufacturing techniques are employed in the production of these pallets, often utilizing high-strength materials that can endure the demanding conditions within production environments.

Manufacturing Process of Mold Pallets

frc concrete pipe mold pallet factories

The manufacturing process of mold pallets in FRC concrete pipe factories involves several steps. Initially, raw materials such as high-strength steel or reinforced plastic are sourced. These materials are then shaped into pallets using processes like stamping, welding, or injection molding, depending on the design requirements.

Quality control is paramount during the manufacturing of mold pallets. Each pallet is rigorously tested for strength, durability, and dimensional accuracy to ensure they meet industry standards. Factors such as load-bearing capacity, resistance to wear, and the ability to maintain surface integrity over multiple uses are carefully evaluated.

Advantages of Utilizing FRC Concrete Pipe Mold Pallets

The advantages of utilizing high-quality mold pallets in FRC concrete pipe production are numerous. One of the most significant benefits is the consistency it brings to the manufacturing process. Standardized mold pallets help ensure uniform size and quality of the pipes produced, thereby minimizing defects and increasing production efficiency.

Additionally, durable mold pallets contribute to cost savings over time. By reducing wear and tear, these pallets can withstand numerous production cycles, leading to lower replacement rates and maintenance costs. This longevity is particularly important for manufacturers aiming to optimize their production processes while ensuring sustainability.

Conclusion

FRC concrete pipe mold pallet factories play a significant role in the construction industry by producing robust, high-quality pipes necessary for modern infrastructure. With advancements in technology and manufacturing processes, these factories are at the forefront of innovation, ensuring that the demands of urban development and infrastructure resilience are met. As the need for effective drainage systems continues to grow, the importance of efficient manufacturing processes and durable materials will remain paramount. Investing in high-quality mold pallets is not just a strategy for enhanced production but also a commitment to building a sustainable future.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025