- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 18, 2024 06:32 Back to list

Heat Exchanger Design for Efficient Gas Cooling Systems

Understanding Gas Cooler Heat Exchangers Principles and Applications

In the realm of mechanical engineering and thermodynamics, heat exchangers play a critical role in a wide range of industrial applications. Among these, gas cooler heat exchangers have gained increasing attention due to their efficiency in cooling gases, which is essential for various processes, including refrigeration, power generation, and chemical manufacturing. This article delves into the principles, operational mechanisms, and applications of gas cooler heat exchangers.

Principles of Gas Cooler Heat Exchangers

Gas cooler heat exchangers are designed to transfer heat from a gas to a cooling medium, usually air or water, without mixing the two phases. The fundamental principle behind these heat exchangers is the second law of thermodynamics, which states that heat flows naturally from a hotter object to a cooler one. The effectiveness of a gas cooler is determined by its ability to maximize this heat transfer while minimizing energy losses.

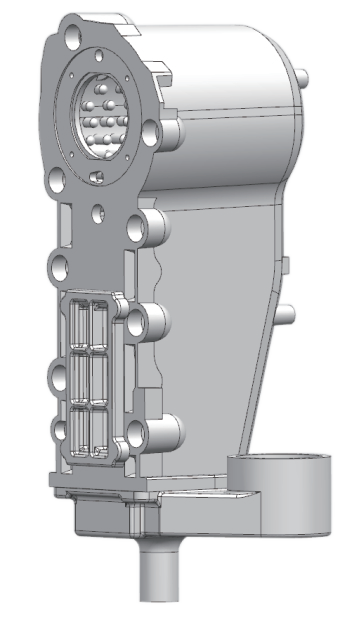

The primary components of a gas cooler heat exchanger include the heat transfer surface, the gas inlet and outlet, the cooling medium inlet and outlet, and insulation to reduce heat loss. The heat transfer surfaces are typically made of highly conductive materials such as aluminum or copper, enabling efficient thermal conduction. The design may vary; some common configurations include shell-and-tube, plate, and finned-tube designs, each selected based on the specific requirements of the application.

Operational Mechanisms

In operation, the hot gas enters the cooler and flows through the designated pathways, while the cooling medium circulates in separate channels. As the hot gas travels through the heat exchanger, it releases its heat to the cooling medium via conduction through the heat transfer surfaces. As a result, the gas temperature decreases while the cooling medium absorbs this heat, increasing its temperature. The effectiveness of this process is influenced by various factors, including flow rates, temperature differentials, and the type of heat exchanger design.

gas cooler heat exchanger

One significant advantage of gas cooler heat exchangers is their ability to operate under varying conditions. For instance, they can maintain efficiency across a range of gas compositions and temperatures, making them versatile options for different industries. Moreover, many modern gas coolers are equipped with sensors and controls that optimize performance by adjusting flow rates and cooling capacity based on real-time operational parameters.

Applications

Gas cooler heat exchangers are widely employed in multiple sectors. One prominent application is in refrigeration systems, where they are used to lower the temperature of refrigerant gases before they enter the compressor or expansion valve. This process increases the efficiency of the refrigeration cycle and reduces energy consumption.

In the petrochemical industry, gas coolers are essential for processes such as gas conditioning and carbon capture, where they help manage the temperature and pressure of gases during extraction and processing. Additionally, in power plants, gas coolers facilitate the efficient operation of gas turbines by pre-cooling the inlet air, enhancing overall energy output.

Moreover, advances in technology have led to the development of innovative gas cooler designs equipped with enhanced heat exchange features. For example, using microchannel technology can significantly increase the surface area for heat transfer, thus improving efficiency in compact designs.

Conclusion

Gas cooler heat exchangers are indispensable components in many industrial processes, contributing to improved energy efficiency and operational performance. Their ability to effectively manage gas temperatures in various applications underscores the importance of heat transfer technology in modern engineering. As industries continue to evolve and seek sustainable practices, the role of gas cooler heat exchangers will likely expand, driving innovations that further optimize energy use and environmental footprint. Understanding these systems is crucial for engineers, designers, and operators who aim to harness their full potential in diverse applications.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025