- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 09, 2024 17:26 Back to list

Gravity Casting Exporters and Their Global Market Impact

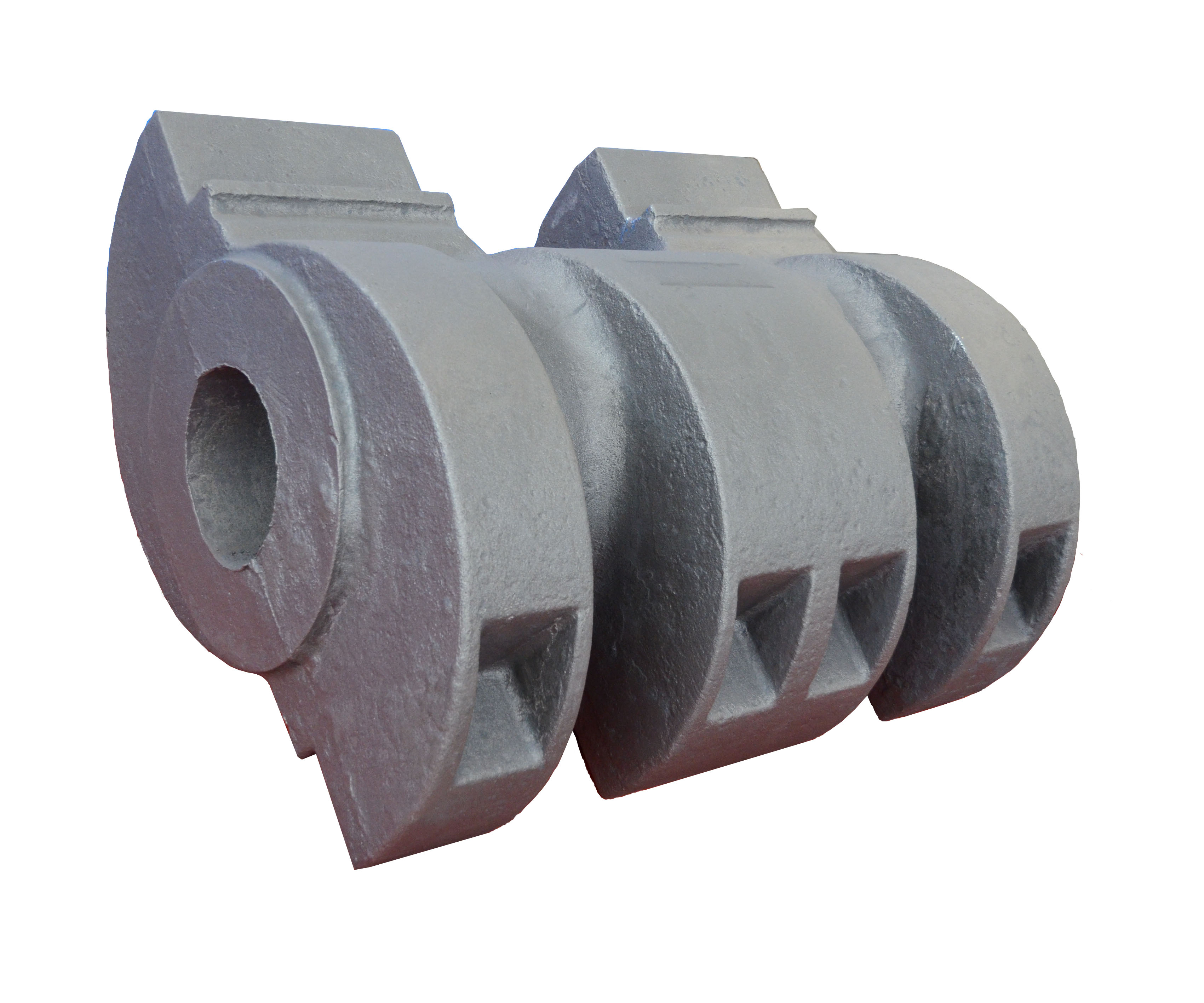

Gravity Casting Exporters An Overview of the Industry

Gravity casting is a widely used manufacturing process in the metal casting industry, especially known for its efficiency and ability to produce high-quality components. This method involves pouring molten metal into a mold under the influence of gravity, making it a cost-effective and reliable technique for creating intricate parts. The process is particularly favored in industries such as automotive, aerospace, and consumer goods due to its ability to produce durable and precise components.

As the demand for gravity-cast products continues to rise, the role of gravity casting exporters has become increasingly significant. These exporters are crucial in supplying high-quality cast products to various markets worldwide. They not only provide the necessary craftsmanship and expertise in manufacturing but also ensure that products meet international standards and specifications.

One of the primary advantages of gravity casting is its versatility. It can be applied to various metals, including aluminum, zinc, and magnesium alloys. This flexibility allows exporters to cater to diverse industries, from producing lightweight automotive parts to creating robust components for industrial machinery. As each sector has specific requirements, gravity casting exporters often work closely with clients to develop customized solutions that meet their unique specifications.

The global market for gravity casting is driven by several factors. The increasing need for lightweight and high-strength materials in the automotive and aerospace sectors is propelling growth in this industry. Manufacturers are continually seeking ways to reduce vehicle weight to enhance fuel efficiency, which drives the demand for aluminum and magnesium cast products. Consequently, exporters play a pivotal role in maintaining the supply chain, ensuring timely delivery of quality parts to manufacturers and assembly lines.

gravity casting exporters

Additionally, technological advancements have contributed to the evolution of gravity casting techniques. Innovations in foundry equipment and mold design have improved the efficiency and precision of the casting process. Exporters who invest in the latest technologies can offer superior products that meet stringent quality controls, thereby gaining a competitive edge in the market.

When it comes to quality assurance, gravity casting exporters are expected to maintain rigorous standards throughout the production process. This includes sourcing high-grade raw materials, implementing effective quality control measures, and adhering to industry regulations. Exporters often engage in certifications such as ISO 9001 to demonstrate their commitment to quality management systems. Such certifications not only enhance their credibility but also reassure buyers about the reliability of the products they are purchasing.

Another crucial aspect of the gravity casting export business is the logistics involved in the transportation of products. Since cast components can be heavy and bulky, effective logistics solutions are essential to ensure that products reach their destination safely and on time. Exporters must also navigate various international trade regulations, tariffs, and customs procedures, which can be complex and time-consuming. Establishing strong relationships with logistics partners can streamline this process and minimize potential delays.

In conclusion, gravity casting exporters play a vital role in the global supply chain for metal components. Their ability to produce high-quality, customized solutions using advanced technology positions them as key players in various industries. As global demand for lightweight and durable products continues to surge, the importance of these exporters is expected to grow. By focusing on quality, innovation, and efficient logistics, gravity casting exporters can meet the evolving needs of their clients and contribute significantly to the advancement of the manufacturing sector. As the industry evolves, those who adapt to new technologies and maintain high standards will thrive in the competitive casting market.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025