- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 28, 2024 22:59 Back to list

Creating a Custom Handle Manufacturing Solution for Your Needs

Understanding Handle Factory The Art and Craft of Handle Production

In the world of manufacturing, various components play crucial roles in the functionality and usability of products. Among these components, handles stand out due to their significance in everyday items, ranging from furniture to appliances. A handle factory specializes in the production of these essential parts, combining technology, craftsmanship, and design to deliver high-quality handles that meet diverse consumer needs.

A handle factory typically utilizes a range of materials, including plastic, metal, wood, and composite substances, to create handles tailored for specific applications. The choice of material affects not only the aesthetic appeal of the handle but also its durability and functionality. For example, metal handles offer robustness and can withstand heavy usage, making them ideal for tools or appliances. In contrast, wooden handles often provide a classic look and a comfortable grip, appealing to furniture designers and homeowners alike.

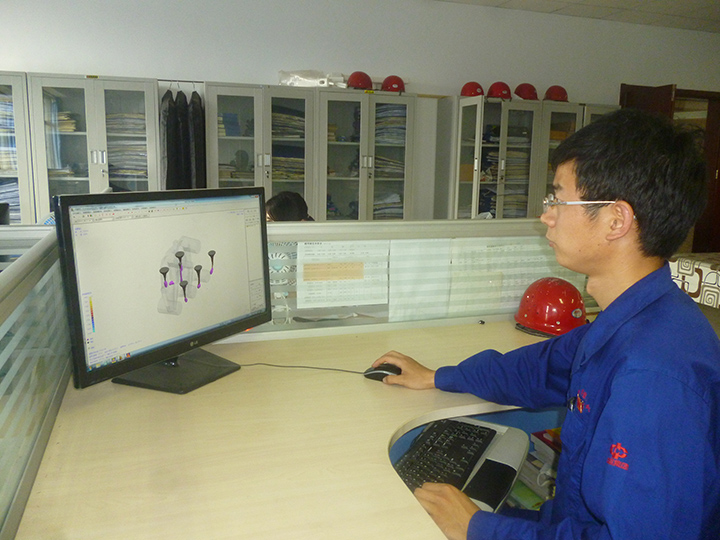

The production process in a handle factory involves several key steps. Initially, design engineers create detailed specifications and prototypes of the handles using computer-aided design (CAD) software. This step is crucial, as it ensures that the handles are ergonomic and visually appealing. After finalizing the designs, the factory moves on to the manufacturing stage, which can include processes like injection molding for plastics, die casting for metals, or woodworking techniques for wooden handles.

handle factory

Quality control is another vital aspect of operations in a handle factory. To ensure that each handle meets the required standards, rigorous testing is performed throughout the manufacturing process. This can involve stress testing for durability, checking for surface imperfections, and ensuring consistent dimensions. By adhering to strict quality control measures, handle factories can minimize defects and enhance customer satisfaction.

Additionally, handle factories often embrace technological advancements to improve efficiency and sustainability. Automation in the production line can significantly increase output while reducing labor costs. Moreover, many manufacturers are shifting towards eco-friendly practices, sourcing sustainable materials and employing processes that minimize waste. This commitment to sustainability is not only beneficial for the environment but also resonates with increasingly eco-conscious consumers.

Customization is another trend gaining traction in the handle manufacturing industry. Many handle factories offer bespoke services, allowing clients to choose materials, colors, sizes, and designs that fit their specific needs. This flexibility enables furniture makers, appliance manufacturers, and other businesses to differentiate their products in a competitive market.

In conclusion, a handle factory plays a critical role in modern manufacturing by producing essential components that enhance the function and aesthetics of countless products. Through a combination of skilled craftsmanship, advanced technology, and a focus on quality and customization, these factories contribute significantly to the global supply chain. As consumer preferences evolve and sustainability becomes a priority, handle factories are well-positioned to innovate and adapt, ensuring that they continue to meet the needs of both manufacturers and consumers alike.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025