- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 01, 2024 01:39 Back to list

High-Performance Heat Exchanger for Low Nitrogen Condensing Boilers - Reliable Exporter

Heat Exchanger for Low Nitrogen Condensing Boiler A Critical Component for Efficient Design

In the modern landscape of heating technology, low nitrogen condensing boilers have emerged as a sustainable solution to energy efficiency and minimized emissions. At the heart of these systems lies a crucial element the heat exchanger. This device not only enhances the overall efficacy of the boiler but also plays a vital role in adhering to stringent environmental regulations.

A heat exchanger in a low nitrogen condensing boiler operates by transferring heat from the combustion gases to the water that circulates through the heating system. This process increases the overall thermal efficiency of the boiler, enabling it to extract more heat from the fuel consumed. Unlike traditional boilers, which expel much of the heat through the flue gases, condensing boilers can utilize this often-wasted energy. The design of these heat exchangers is specifically optimized to maximize contact between the combustion gases and the water, ensuring that as much heat as possible is absorbed.

Moreover, one of the significant advantages of low nitrogen condensing boilers is their ability to significantly reduce nitrogen oxide (NOx) emissions, a key contributor to air pollution. This reduction is achieved through the efficient operation of the heat exchanger, which allows the boiler to operate at lower temperatures, thereby minimizing the formation of NOx during the combustion process. Many regions are now imposing strict limits on NOx emissions, and the use of advanced heat exchangers is instrumental in achieving compliance.

heat exchanger for low nitrogen condensing boiler exporter

The materials used in manufacturing heat exchangers for these boilers are also of paramount importance. High-grade stainless steel and aluminum are commonly employed because of their excellent resistance to corrosion and ability to withstand high temperatures. This durability not only extends the lifespan of the heat exchanger but also enhances the reliability of the boiler system as a whole.

In terms of exporting these innovative heat exchanger technologies, manufacturers must ensure that they comply with international standards and regulations regarding efficiency and emissions. This is crucial for gaining acceptance in various markets that prioritize sustainability. Companies involved in the export of heat exchangers must also focus on providing excellent customer service and support, as these systems often require specialized installation and maintenance.

In conclusion, the heat exchanger is a vital component of low nitrogen condensing boilers that significantly contributes to energy efficiency and environmental sustainability. As global energy demands continue to rise, innovations in heat exchanger technology will be essential in ensuring that heating systems are both effective and eco-friendly. The ongoing development and export of these technologies will play a key role in shaping the future of sustainable heating solutions.

-

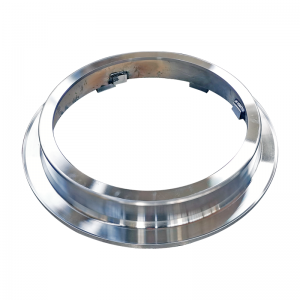

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025