- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 12, 2024 21:11 Back to list

Leading Heat Exchanger Suppliers and Manufacturers in Germany for Industrial Applications

Heat Exchanger Manufacturers in Germany Leaders in Innovation and Efficiency

Germany has long been recognized as a global powerhouse in engineering and manufacturing, particularly in sectors focused on innovation and sustainability. Among the key contributors to this reputation are heat exchanger manufacturers, which play a crucial role in a wide array of industries such as power generation, chemical processing, automotive, and HVAC (heating, ventilation, and air conditioning). These manufacturers not only cater to domestic needs but also hold significant influence in international markets.

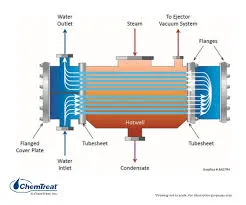

A heat exchanger is a vital component that allows the transfer of heat between two or more fluids without mixing them. This process is essential for improving energy efficiency, reducing operational costs, and minimizing environmental impact. Given the increasing focus on energy efficiency and sustainability worldwide, the demand for high-performance heat exchangers has surged, making Germany home to some of the leading manufacturers in this field.

Heat Exchanger Manufacturers in Germany Leaders in Innovation and Efficiency

One of the remarkable aspects of German manufacturers is their focus on customization. Understanding that each industrial application has unique requirements, these companies work closely with clients to design and produce tailored heat exchanger solutions. This client-centric approach not only enhances efficiency but also optimizes operational costs for businesses in industries ranging from food and beverage to pharmaceuticals.

heat exchanger manufacturer in germany

Sustainability is another vital focus for German heat exchanger manufacturers. Many of these companies are actively developing solutions that align with the European Union's stringent climate goals. The integration of heat recovery systems into industrial processes is one such innovation that allows companies to recycle waste heat, contributing to significant energy savings. This proactive stance on sustainability not only benefits the environment but also allows businesses to improve their bottom lines through enhanced efficiency.

Furthermore, German manufacturers adhere to rigorous quality control standards, ensuring that products meet local and international regulations. The quality assurance processes, often certified to ISO standards, guarantee the longevity and reliability of heat exchangers, which are essential in critical applications. For end-users, the assurance of high-quality products translates into reduced downtime and maintenance costs, ultimately leading to more efficient operations.

In addition to their engineering prowess, German heat exchanger manufacturers are characterized by their strong after-sales support and service. This commitment to customer service ensures that clients receive guidance throughout the lifecycle of the product, from installation to regular maintenance. Manufacturers often provide comprehensive training programs for client staff, ensuring that they are well-equipped to operate and maintain the equipment effectively.

The global competition in the heat exchanger market is intense, but German manufacturers leverage their engineering heritage, innovation, and commitment to sustainability to maintain a competitive edge. As industries continue to evolve and emphasize energy efficiency, the role of heat exchanger manufacturers in Germany will remain pivotal. With a combination of innovation, quality, and service, these companies are not only meeting current market demands but also shaping the future landscape of thermal management technologies.

In conclusion, the heat exchanger manufacturing industry in Germany exemplifies a successful blend of tradition and modernity. With a keen focus on innovation, sustainability, and customer satisfaction, German manufacturers are setting benchmarks that influence global practices and lead the charge towards more efficient energy solutions.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025