- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 01, 2024 06:26 Back to list

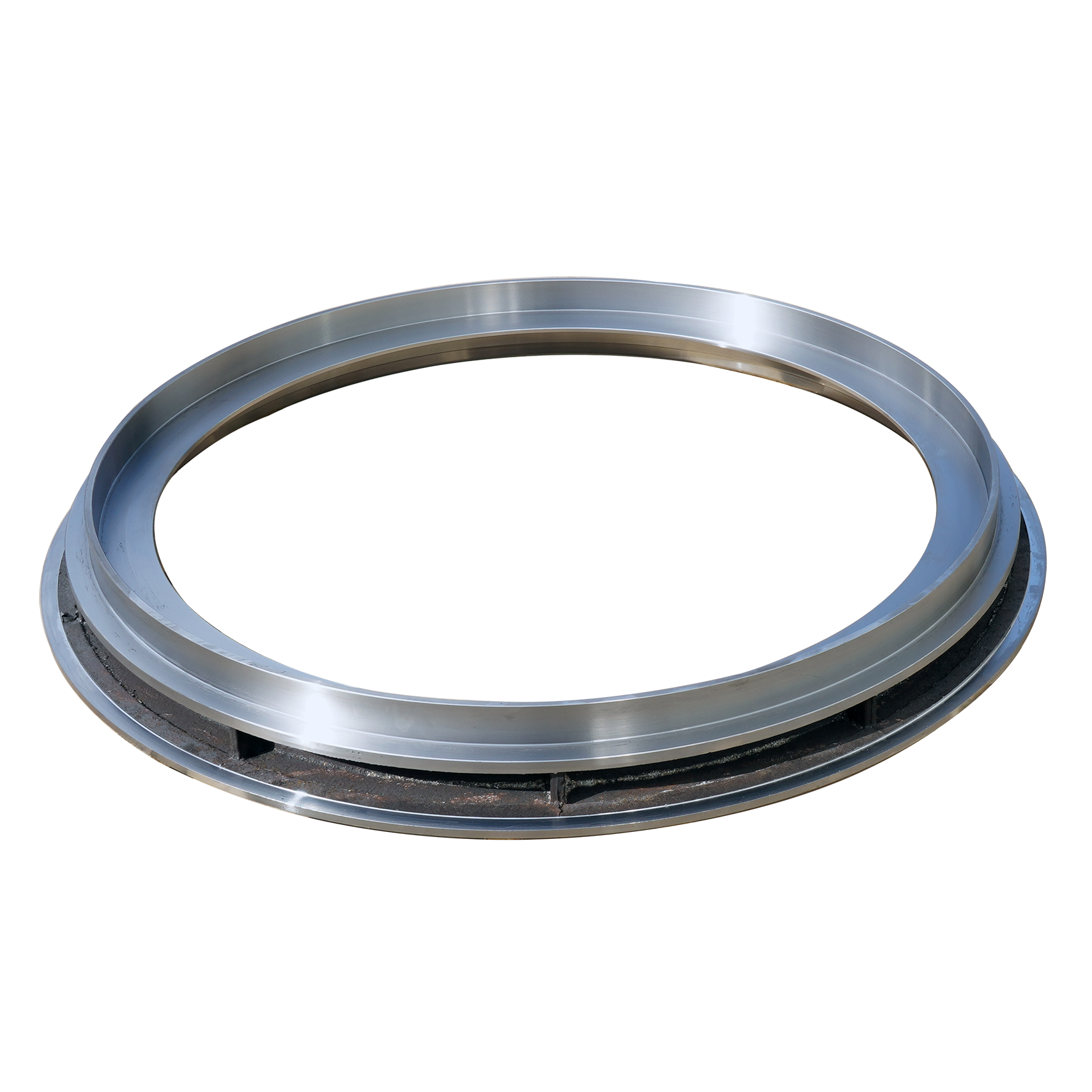

High-Quality Ductile Iron Manufacturers for Reliable Industrial Applications and Exceptional Performance Solutions

Understanding Ductile Iron The Benefits and Applications

Ductile iron, also known as spheroidal graphite iron or nodular cast iron, is a type of cast iron that has gained immense popularity in various sectors due to its remarkable mechanical properties and versatility. Manufactured through a process that involves the addition of a small amount of magnesium to molten iron, ductile iron exhibits enhanced strength, shock resistance, and ductility compared to traditional cast iron. This unique combination of properties makes ductile iron an ideal material for a wide range of applications in several industries.

The Manufacturing Process

The production of ductile iron begins with the melting of iron, followed by the addition of carbon and other alloying elements. The critical step that differentiates ductile iron from other cast irons is the addition of spheroidizing agents, typically magnesium and cerium. These elements promote the formation of spherical graphite, as opposed to the flake-like structures found in conventional cast iron. This spherical morphology provides enhanced strength and toughness, making ductile iron particularly suitable for demanding applications.

Manufacturers often utilize advanced casting techniques, such as sand casting, investment casting, or centrifugal casting, to achieve the desired properties in ductile iron components. Through controlled cooling rates and the careful management of chemical compositions, manufacturers can produce ductile iron with varying grades, which enables customization for specific applications and performance requirements.

Benefits of Ductile Iron

One of the standout features of ductile iron is its combination of strength and ductility. It can absorb energy and withstand deformation under load, which makes it resistant to cracking. This property is particularly beneficial in applications where components are subjected to shock loads or stress, such as in the manufacturing of automotive parts, machine components, and heavy machinery.

ductile iron manufacturer

Additionally, ductile iron has excellent wear resistance, which contributes to its longevity in demanding applications. Its corrosion resistance is also noteworthy, especially when treated with coatings or surface modifications, allowing it to perform well in harsh environments. These attributes contribute to reduced maintenance costs and enhance the safety of components made from ductile iron.

Applications Across Industries

The versatility of ductile iron allows for its use in a wide range of industries. In the automotive sector, it's employed in the production of engine blocks, crankshafts, and transmission cases, where strength and weight reduction are critical. The oil and gas industry also utilizes ductile iron in piping systems, valves, and fittings, where the material’s robustness is necessary for safety and durability.

Infrastructure projects often rely on ductile iron for manufacturing manhole covers, water pipes, and other utility components that require high performance and reliability. In the agricultural sector, ductile iron is used in the production of equipment like plows and tillers, where durability is essential for effective operation.

Conclusion

In summary, ductile iron manufacturers play a crucial role in delivering high-quality materials that meet the demanding needs of various industries. With its unique combination of strength, ductility, and wear resistance, ductile iron stands as a superior alternative to conventional casting materials. As industries continue to evolve and require materials that can withstand greater stresses and harsher environments, the demand for ductile iron is expected to grow. Manufacturers must focus on innovation and quality to maintain their competitive edge and meet the evolving needs of the market. As a result, ductile iron will remain a fundamental material in engineering and manufacturing, shaping the future of numerous applications across the globe.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025