- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 30, 2024 13:56 Back to list

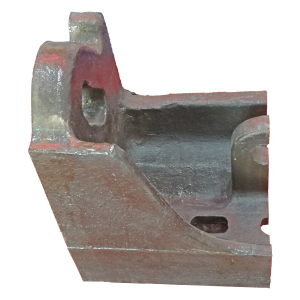

high quality sand cast

The Importance of High-Quality Sand Casting in Manufacturing

Sand casting is one of the oldest and most versatile manufacturing processes used to create metal parts and components. It involves pouring molten metal into a mold made of sand, allowing it to solidify into the desired shape. While this process has been employed for centuries, the quality of sand used plays a crucial role in determining the effectiveness and precision of the final product. In this article, we will explore the significance of high-quality sand casting and its impact on various industries.

The Importance of High-Quality Sand Casting in Manufacturing

Moreover, high-quality sand ensures consistency in the casting process. This is essential, especially in industries such as aerospace, automotive, and medical equipment, where precision is paramount. Using consistent materials reduces variability, helping manufacturers achieve tighter tolerances and improved mechanical properties in the finished parts. High-quality sand also facilitates better sand reclamation, which not only saves costs but also promotes environmental sustainability by reducing waste.

high quality sand cast

Another notable benefit of high-quality sand casting is its adaptability to various metals and alloys. Whether working with aluminum, bronze, iron, or steel, the right sand composition can be tailored to suit the specific melting points and characteristics of different materials. This versatility allows engineers and designers to experiment with various casting solutions, ultimately leading to innovative applications undreamed of in traditional manufacturing setups.

Furthermore, high-quality sand casting can significantly reduce the time and costs associated with secondary operations. When sand casting is done right, there is often less need for machining or surface finishing, since high-quality molds provide superior surface finishes and dimensional accuracy. This not only shortens production cycles but also enhances overall productivity, allowing companies to meet customer demands more efficiently.

In conclusion, the role of high-quality sand in the sand casting process cannot be overstated. It directly impacts the mechanical properties, surface quality, and overall performance of cast products. As industries continue to demand higher precision and durability in components, investing in high-quality sand casting materials and techniques is crucial. Embracing advancements in sand quality and processing will undoubtedly lead to the creation of more reliable and efficient products across various applications, making high-quality sand casting a cornerstone of modern manufacturing practices.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025