- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 09, 2024 18:50 Back to list

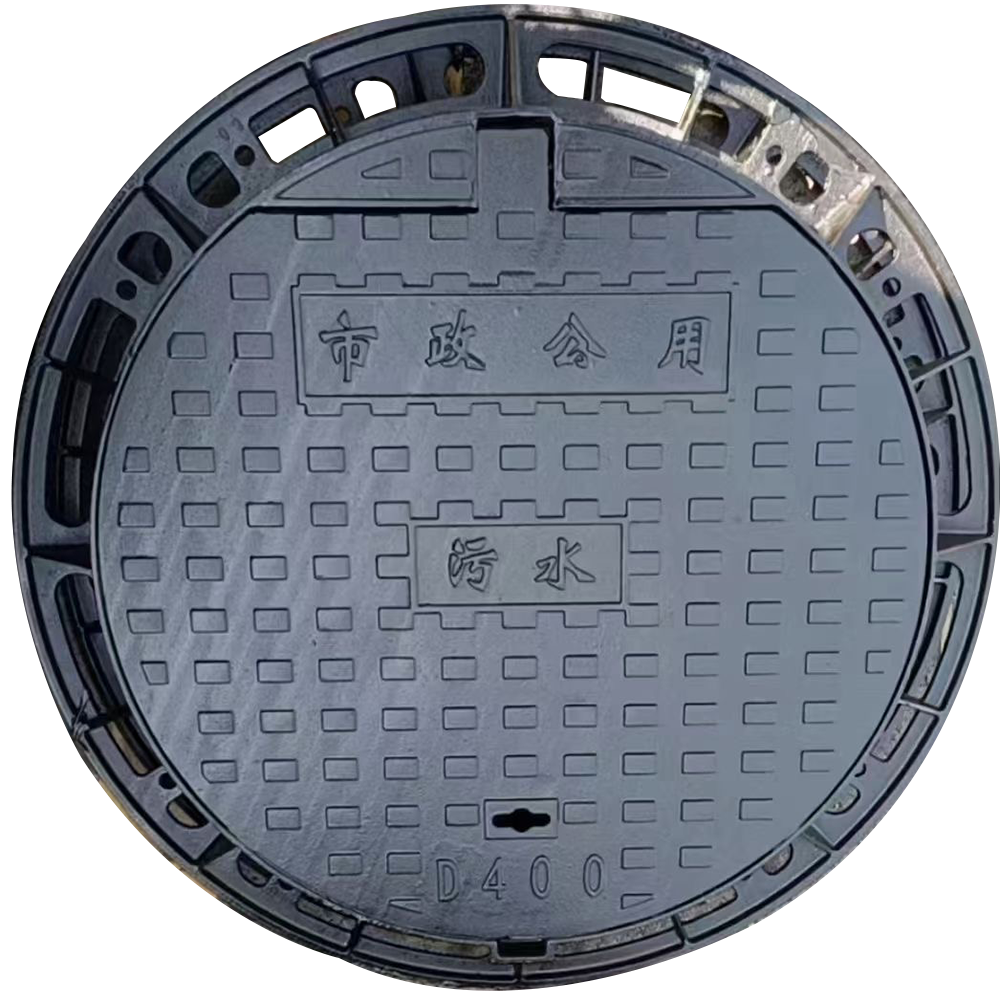

High-Quality Mold for Concrete and Cement Pipe Bottom Ring Production

The Importance of High-Quality Concrete and Cement Pipe Molds A Focus on Mould Bottom Rings

In the construction and manufacturing industries, efficiency, durability, and precision are paramount. Among the many components utilized in these sectors, concrete and cement pipe molds play a crucial role in ensuring that structures are reliable and long-lasting. One particular element of these molds, the mould bottom ring, is often overlooked but is essential for producing high-quality concrete products.

What Are Concrete and Cement Pipe Molds?

Concrete and cement pipe molds are specialized tools used to shape and form concrete into desired configurations. These molds can produce a wide range of products, including pipes, slabs, and other construction materials. The quality of these molds directly impacts the integrity and longevity of the concrete products produced.

High-quality molds are made from durable materials such as steel, aluminum, or heavy-duty plastics. They must withstand the harsh conditions of concrete pouring and curing processes. In particular, they need to resist wear and deformation as concrete is incredibly heavy and aggressive during the curing phase.

The Role of Mould Bottom Rings

The mould bottom ring is a key component in the overall functionality of concrete and cement pipe molds. Positioned at the base of the mold, these rings serve multiple purposes

1. Structural Support Mould bottom rings provide essential support to the entire mold structure. They help maintain the shape of the mold during the curing phase when the concrete is in its most fluid state.

2. Alignment Bottom rings aid in aligning various sections of the mold, ensuring that concrete is poured evenly and that the final product maintains consistency in size and shape. Their precision design is critical for producing pipes and other components that must fit together seamlessly during installation.

high quality concrete/cement pipe mold/mould bottom ring

4. Enhanced Finish Quality The design and finish of the bottom ring directly influence the surface finish of the concrete product. High-quality bottom rings lead to smoother finishes, reducing the need for further treatment or smoothing of the concrete after it has cured.

The Benefits of Investing in High-Quality Mould Bottom Rings

Investing in high-quality mould bottom rings can yield significant long-term benefits for manufacturers and contractors

- Cost Efficiency While high-quality moulds may entail a larger upfront investment, they result in fewer defects and better operational efficiency. This translates to lower rework costs and minimized downtime.

- Improved Product Quality The use of reliable bottom rings leads to higher-quality end products. Concrete pipes and structures produced with precision molds exhibit greater durability, leading to lower maintenance costs over time.

- Enhanced Safety By ensuring the structural integrity of the molds, high-quality bottom rings contribute to safer working conditions. Reduced chances of mold failure mean lower risk for workers involved in the casting process.

- Environmental Sustainability With the global focus on sustainability in construction, the durability of high-quality concrete products contributes to longer life cycles and decreased waste. Longer-lasting pipes and structures mean fewer resources are consumed over time.

Conclusion

In the world of construction and manufacturing, the importance of high-quality concrete and cement pipe molds cannot be overstated, particularly when it comes to mould bottom rings. These components ensure structural integrity, alignment, and surface finish quality—all crucial for producing reliable and long-lasting concrete products.

Investing in high-quality mould bottom rings is an investment in durability, efficiency, and overall product excellence. As the industry continues to evolve, the emphasis on using advanced materials and technologies to enhance the quality of molds will only increase. For manufacturers and contractors striving for excellence, prioritizing the quality of mould components such as bottom rings is essential in achieving successful project outcomes. In an era where competition is fierce and standards are high, the choice is clear quality molds lead to quality results.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025