- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 30, 2024 02:04 Back to list

High-Quality Concrete Pipe Mold with Durable Bottom Ring for Optimal Performance

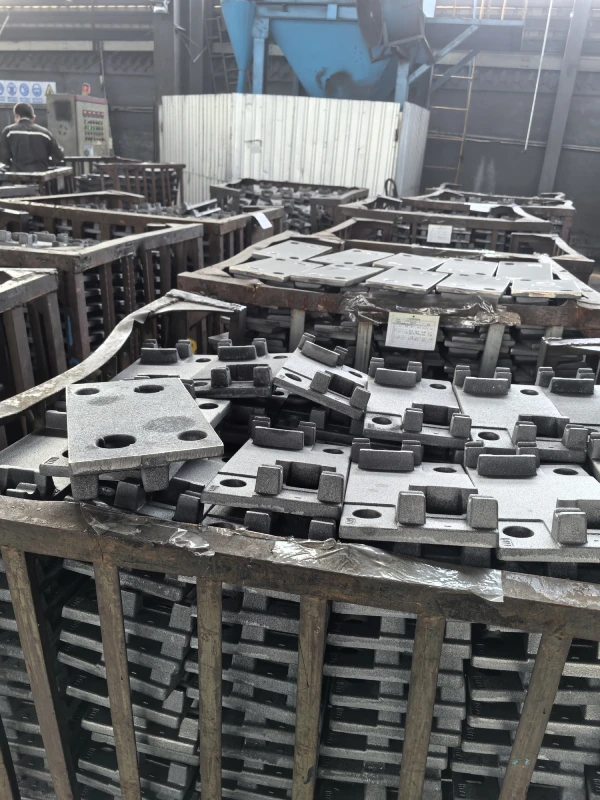

High-Quality Punching Concrete Pipe Mold Bottom Ring An Essential Component in Modern Construction

In the world of modern construction, the quality of materials and components used can significantly influence the overall integrity and durability of a structure. One such crucial element is the bottom ring of concrete pipe molds, particularly those designed for punching applications. This article delves into the significance, manufacturing processes, and benefits of high-quality punching concrete pipe mold bottom rings.

Concrete pipes are widely used in various civil engineering projects, including drainage systems, sewer lines, and water supply systems. The effectiveness of these infrastructure components heavily relies on the quality of the molds used to produce them. The bottom ring of a concrete pipe mold plays an integral role in supporting the weight and structure of the pipe during the casting process. For this reason, it is imperative that the bottom rings are manufactured to high standards, ensuring they can withstand the pressures encountered during production.

Manufacturing Process Precision and Durability

The manufacturing of high-quality punching concrete pipe mold bottom rings involves several key steps

1. Material Selection The first step in producing a durable bottom ring is the selection of suitable raw materials. Typically, high-strength steel or reinforced materials are chosen to ensure the mold can bear the heavy loads during production without warping or breaking.

2. Design Specifications Accurate design specifications are essential. Engineers and designers use advanced software to create precise blueprints for the bottom ring, taking into account the dimensions, shape, and tolerance levels needed for optimal performance.

3. Fabrication Once the design is finalized, the fabrication process begins. This involves cutting, welding, and assembling the components of the bottom ring. Skilled technicians utilize state-of-the-art machinery to ensure each piece is crafted with precision, promoting uniformity across all molds produced.

4. Finishing Touches After assembly, the bottom rings undergo a series of finishing processes, including grinding, painting, and surface treatment. These steps enhance the structural integrity of the rings by preventing corrosion and wear, extending their lifespan significantly.

high quality punching concrete pipe mold bottom ring

5. Quality Control Before the bottom rings are delivered for use, they go through rigorous quality control inspections. These assessments are crucial for identifying any defects and ensuring that each product meets industry standards.

Benefits of High-Quality Bottom Rings

Investing in high-quality punching concrete pipe mold bottom rings offers multiple advantages

- Enhanced Durability Superior materials and craftsmanship lead to longer-lasting molds, reducing the need for frequent replacements. This not only saves costs but also minimizes downtime during production.

- Precision in Production Molds designed with high accuracy ensure that the concrete pipes produced are uniformly shaped and sized. This precision is critical in ensuring they fit well into drainage and sewer systems, preventing leaks and structural failures.

- Increased Efficiency High-quality molds speed up the production process. Their robust design allows for quicker curing times, which accelerates overall project timelines.

- Safety Assurance With high-quality bottom rings, the risk of mold failure during the concrete pouring process is significantly decreased. This safety factor protects workers and equipment, promoting a safer working environment.

Conclusion

In summary, the bottom ring of concrete pipe molds is a fundamental component in the production of concrete pipes. Its quality directly impacts the structural integrity and durability of the resulting pipes. By emphasizing high-quality manufacturing processes, the construction industry can ensure that its infrastructure is robust and reliable. As projects evolve, especially those that require sustainable and long-lasting solutions, the significance of investing in quality components like the punching concrete pipe mold bottom ring becomes increasingly evident.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025