- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 11, 2024 17:50 Back to list

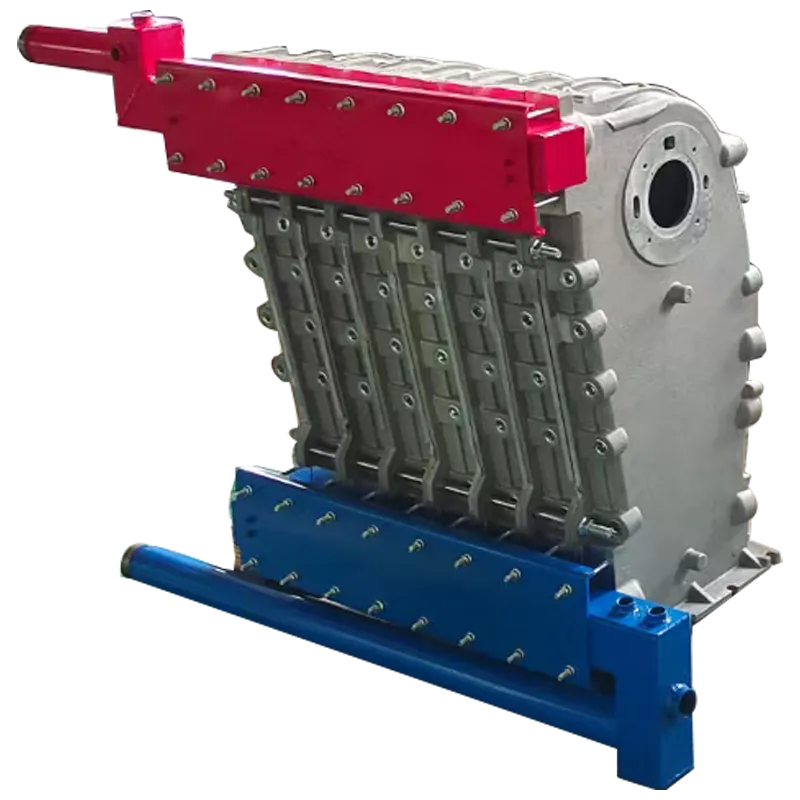

high quality src concrete pipe mold bottom ring

High-Quality SRC Concrete Pipe Mold Bottom Ring A Key Element in Modern Construction

In the ever-evolving field of construction, the demand for durable and efficient materials has never been more pronounced. One of the critical components that plays a significant role in ensuring the integrity of concrete infrastructures is the bottom ring of SRC (Steel Reinforced Concrete) pipe molds. This article explores the importance, composition, and manufacturing process of high-quality SRC concrete pipe mold bottom rings, underscoring their value in modern construction projects.

Understanding SRC Pipes

SRC pipes are known for their strength and durability, making them an excellent choice for various applications, including drainage systems, sewage, and stormwater management. These pipes incorporate steel reinforcement within the concrete, which increases their load-bearing capacity and extends their lifespan. The bottom ring of the mold is an essential part of the pipe manufacturing process, as it forms the base of the pipe and holds it in place during curing.

Importance of High-Quality Bottom Rings

The bottom ring of a concrete pipe mold serves multiple vital functions. First and foremost, it provides stability and support during the pouring and curing phases. This stability is crucial because any movement or misalignment during these stages can lead to defects in the pipe, ultimately compromising its structural integrity.

Moreover, high-quality bottom rings help ensure a perfect seal when the mold is assembled. A poor seal can lead to leakage or contamination in the final product, which is unacceptable in applications related to water management and environmental protection. Therefore, investing in high-quality SRC concrete pipe mold bottom rings is essential for maintaining the overall quality of the pipe.

Composition and Material Considerations

high quality src concrete pipe mold bottom ring

High-quality bottom rings are typically made from robust materials designed to withstand the stresses of concrete pouring and curing. Commonly, they are produced using a combination of high-strength steel and durable casting materials. The steel reinforcement enhances the strength of the bottom ring, while the outer casting can be treated or coated to resist corrosion and wear over time.

Manufacturers often use advanced technologies in the production of these bottom rings to ensure precision. This may include computerized cutting and molding processes that guarantee uniformity in thickness and shape. When each component is consistent, it leads to better performance of the final concrete pipes.

Manufacturing Process

The manufacturing process of high-quality SRC concrete pipe mold bottom rings starts with the selection of superior raw materials. Following this, the design and specifications are established, often employing CAD (Computer-Aided Design) software to create intricate models. The components are then carefully cut and shaped using precision machinery.

Once the initial preparation is complete, the components are welded and assembled to form the bottom ring. Following assembly, surface treatments are applied to enhance durability and resistance properties. Finally, rigorous quality control checks are conducted to ensure that each bottom ring meets the strict industry standards.

Conclusion

In conclusion, the bottom ring of SRC concrete pipe molds is a fundamental component in the construction of reliable and long-lasting concrete pipes. Its quality directly impacts the performance of the pipes, making it essential for manufacturers to prioritize the use of high-quality materials and advanced manufacturing processes. As the construction industry continues to demand innovative and sustainable solutions, investing in superior bottom rings for SRC pipe molds will be instrumental in achieving high-performance outcomes in various infrastructure projects.

Thus, as we move forward into an era of modernization in construction, the role of quality components, like the SRC concrete pipe mold bottom ring, cannot be overstated. It is not just about creating concrete pipes; it is about building a future where safety, efficiency, and durability are paramount.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025