- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 01, 2024 23:44 Back to list

High-Quality Iron Casting Supplier | Custom Iron Foundry Services

Finding the Right Iron Casting Supplier

When it comes to manufacturing components for various industries, iron casting plays a crucial role thanks to its durability, versatility, and cost-effectiveness. As companies seek out reliable iron casting suppliers, it’s essential to consider a few key factors to ensure you partner with the right provider.

Understanding Iron Casting

Iron casting is a process that involves pouring molten iron into a mold to produce various components. These cast parts can be found in a wide range of applications, from automotive to construction and machinery. The quality and specifications of the cast iron components affect not only the performance of the final product but also the safety of the end-user. Therefore, selecting the right supplier is critical.

Evaluating Supplier Capabilities

When looking for an iron casting supplier, assessing their capabilities is of utmost importance. A reputable supplier should have advanced casting techniques and machinery that adhere to industry standards. This includes evaluating their ability to handle different types of cast iron, such as gray cast iron, ductile iron, and nodular iron. Furthermore, their production capacity and turnaround times should align with your project deadlines and volume demands.

Quality Assurance

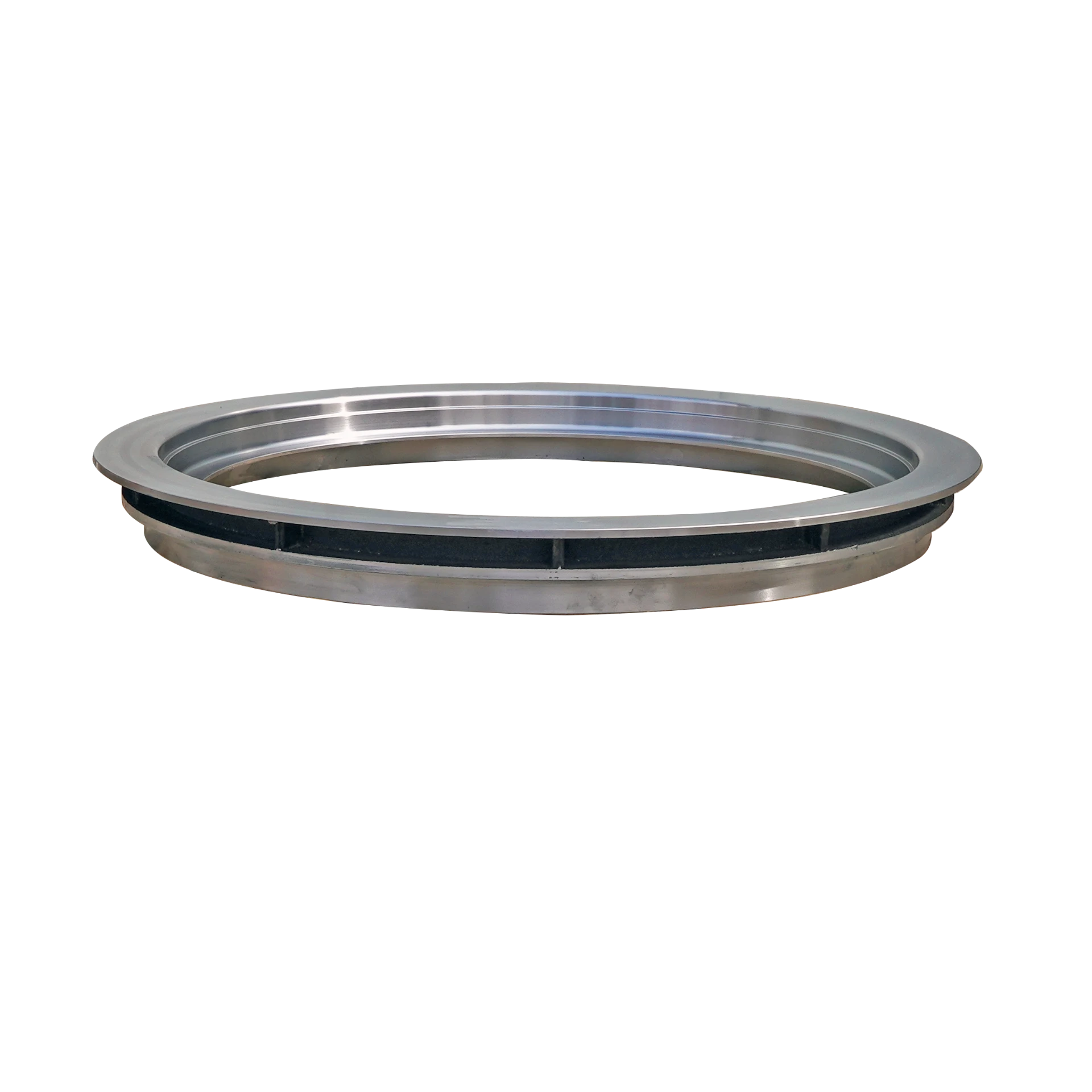

iron casting supplier

Quality assurance is another cornerstone of a reputable iron casting supplier. They should have well-defined processes for quality control, ensuring that every cast part meets specified tolerances and requirements. Certifications such as ISO 9001 can serve as indicators of commitment to quality. Furthermore, a supplier should be willing to share test results, such as tensile strength and metallurgical properties, to prove the reliability of their products.

Customization and Design Support

The ability to customize products according to specific needs sets top suppliers apart. Whether you require unique designs or adaptations for existing products, a good supplier should offer design support services, including engineering consultations and prototype casting. This level of collaboration not only helps in achieving the desired end product but also fosters a strong partnership throughout the manufacturing process.

Pricing and Delivery

While cost is an essential factor, it should not be the sole determinant when selecting an iron casting supplier. It’s crucial to consider the overall value provided, which includes product quality, service, and support. Compare pricing structures among suppliers but weigh them against their quality guarantees and delivery reliability. Timely delivery is vital to maintaining project schedules and avoiding costly delays.

Conclusion

Choosing the right iron casting supplier can significantly impact the success of your project. By carefully evaluating their capabilities, quality assurance practices, customization options, and pricing structures, you can find a partner that meets your specific needs and contributes to your company's success in its respective industry. Take the time to conduct thorough research, as a strong supplier relationship can yield lasting benefits for both parties.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025