- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 17, 2024 23:58 Back to list

lost wax casting exporters

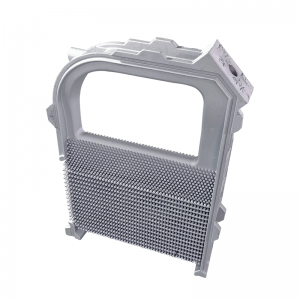

Lost Wax Casting Exporters A Comprehensive Overview

Lost wax casting, also known as investment casting, is a highly refined method of metal casting that has been employed for thousands of years. It plays a crucial role across numerous industries, including jewelry making, aerospace, automotive, and art. The demand for lost wax casting has led to the emergence of numerous exporters around the world, offering high-quality services and products to cater to diverse customer needs. This article delves into the intricacies of lost wax casting exporters and their significance in the global market.

The lost wax casting process involves creating a detailed wax model of the desired object, which is then coated with a refractory material to form a mold. Once the mold is set, the wax is melted away, leaving behind a cavity that is filled with molten metal. This technique allows for intricate designs and precise details, making it ideal for complex components that require high accuracy and quality. Exporters specializing in lost wax casting often provide tailored solutions to meet the specifications of their clients, ensuring that the final products align with the desired designs and standards.

One of the primary advantages of working with lost wax casting exporters is the ability to leverage their expertise and advanced technology. Many of these companies utilize state-of-the-art equipment and follow strict quality control measures to ensure that every casting meets industry standards. This is particularly important in sectors such as aerospace and automotive, where precision and reliability are paramount. By partnering with experienced exporters, businesses can benefit from their extensive knowledge of materials, production techniques, and industry trends.

lost wax casting exporters

As the global economy continues to evolve, the demand for lost wax casting products has surged, leading to increased competition among exporters. Regions such as Asia, Europe, and North America play significant roles in the lost wax casting export market. Countries like India and China have become notable hubs for lost wax casting due to their skilled labor force, cost-effective production capabilities, and the ability to export at competitive prices. Meanwhile, European exporters often emphasize craftsmanship and superior quality, catering to high-end markets.

In addition to quality and expertise, many lost wax casting exporters are increasingly focusing on sustainability and environmentally friendly practices. The manufacturing process can have considerable environmental implications, and exporters are adopting measures to minimize waste and energy consumption. This shift not only appeals to eco-conscious consumers but also aligns with global efforts to combat climate change and promote responsible production methods.

Furthermore, technology has transformed the lost wax casting landscape. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) technology has streamlined the design process, enabling exporters to produce more intricate patterns with enhanced accuracy. This technological advancement has allowed for the creation of customized solutions that were once deemed impossible, opening new avenues for innovation in industries that rely on casting.

In conclusion, lost wax casting exporters play a pivotal role in the global supply chain, providing high-quality casting solutions across various industries. Their expertise, commitment to quality, and focus on sustainable practices position them as vital players in a competitive market. As demand continues to grow, the evolution of technology and an emphasis on eco-friendly processes will likely shape the future of lost wax casting, making it an exciting field for both producers and consumers alike. Engaging with reliable exporters not only enhances product quality but also fosters long-term partnerships that drive mutual growth and success.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025