- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 13, 2024 00:21 Back to list

Low Nitrogen Emission Condensing Gas Boiler for Efficient Commercial Heating Solutions

Low Nitrogen Condensing Gas Fired Boilers for Commercial Heating

In the quest for sustainable and efficient heating solutions, low nitrogen condensing gas fired boilers have emerged as a front-runner in commercial heating systems. These advanced boilers not only provide effective heat but also adhere to stringent environmental regulations, positioning themselves as a key player in the push towards greener technologies.

Understanding Low Nitrogen Condensing Boilers

A low nitrogen condensing boiler operates by maximizing the efficiency of burning natural gas while minimizing harmful emissions. The term condensing refers to the boiler's ability to recover heat from the exhaust gases that would otherwise be expelled into the atmosphere. By condensing the water vapor in the exhaust, the boiler extracts latent heat, raising its overall thermal efficiency significantly—often exceeding 90%.

Benefits of Low Nitrogen Emissions

Nitrogen oxides (NOx) are harmful pollutants released during combustion processes. They contribute to air pollution and are a precursor to smog, which poses health risks and environmental damage. Low nitrogen condensing boilers are designed to burn natural gas in a way that minimizes NOx emissions, often to levels that meet or exceed regulatory standards. This capability not only helps businesses comply with environmental laws but also enhances their corporate social responsibility profile.

Efficiency and Cost-Effectiveness

One of the main advantages of low nitrogen condensing gas fired boilers is their efficiency. Traditional boilers operate at a lower efficiency rate, meaning they require more fuel to generate the same amount of heat. In contrast, these modern systems harness excess heat, effectively reducing fuel consumption and, consequently, operational costs. For commercial enterprises, where heating demands are high, the switch to low nitrogen condensing boilers can lead to significant savings on energy bills over time.

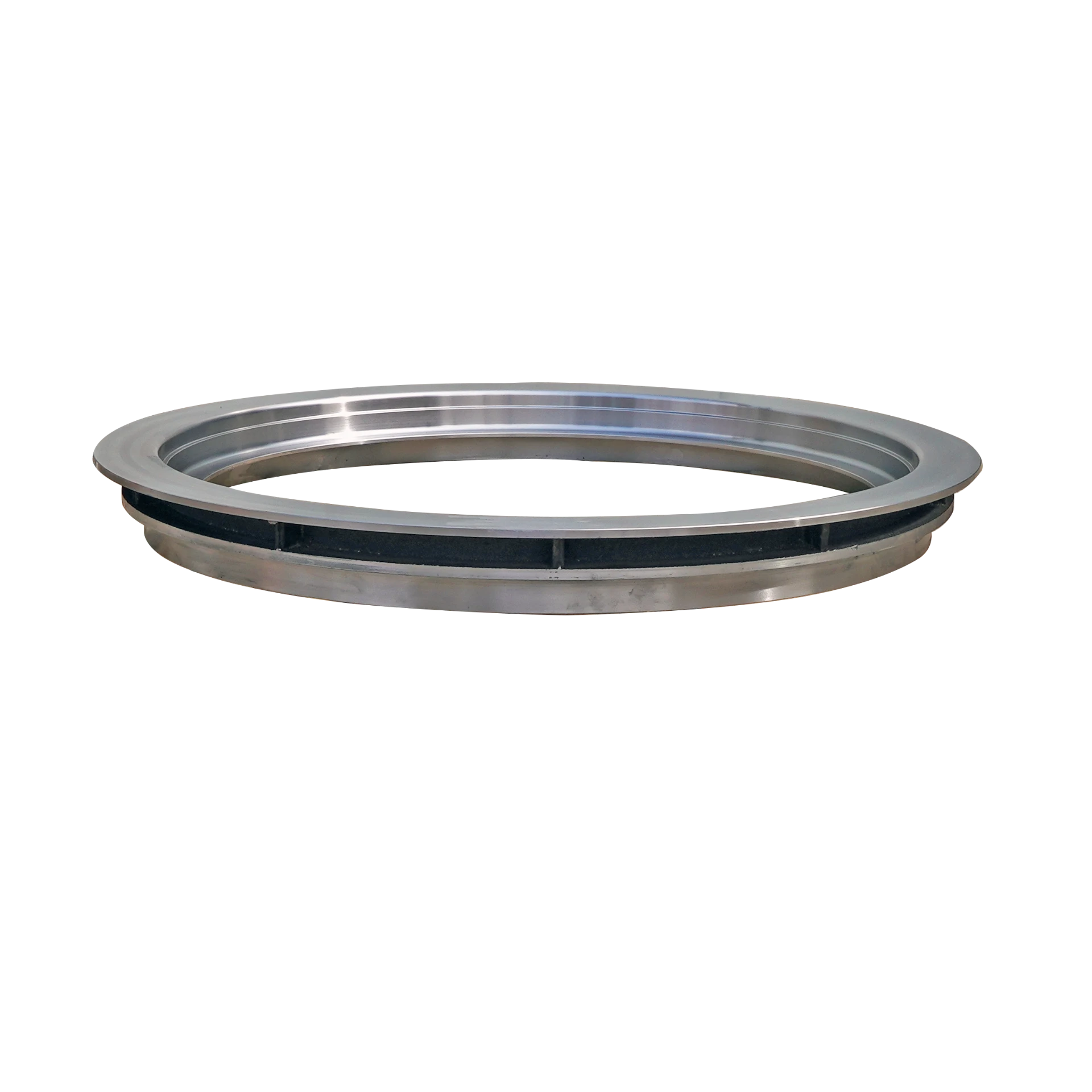

low nitrogen condensing gas fired boiler for commerical heating

Applications in Commercial Settings

The versatility of low nitrogen condensing gas fired boilers makes them suitable for a wide range of commercial applications. They can be utilized in office buildings, hospitals, educational institutions, and manufacturing facilities. Their ability to provide stable and consistent heating is crucial in environments where comfort and operational efficiency are paramount. Moreover, the compact design of many models allows for easy installation in various spaces, facilitating retrofitting in existing systems.

Environmental Impact and Sustainability

As businesses increasingly strive to lower their carbon footprint, low nitrogen condensing gas fired boilers stand out as an environmentally friendly choice. By reducing greenhouse gas emissions and optimizing fuel usage, these boilers contribute to improved air quality and a more sustainable heating solution for the future. Furthermore, many manufacturers are focusing on designing boilers with recyclable materials and energy-efficient components, which enhances their appeal within the sustainability framework.

Future of Commercial Heating Solutions

The market for low nitrogen condensing gas fired boilers is expected to grow as governments and industries push for cleaner technologies. Advances in technology will likely lead to even greater efficiencies and lower emissions. Research and development efforts are focused on refining combustion processes, integrating smart technologies for better control, and improving overall boiler designs.

Conclusion

In summary, low nitrogen condensing gas fired boilers represent a significant advancement in commercial heating technology. They offer a dual benefit of high efficiency and low emissions, making them an attractive choice for businesses aiming to implement environmentally responsible heating systems. As the demand for sustainable practices continues to rise, these boilers will play a crucial role in shaping the future of commercial heating while helping organizations achieve their energy efficiency and sustainability goals. By investing in such technologies, businesses not only enhance their operations but also contribute positively to the environment, setting a standard for future heating solutions.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025