- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 21, 2024 01:51 Back to list

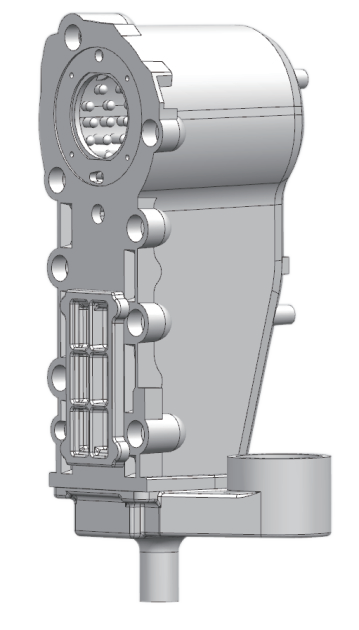

Manufacturing Techniques for Stamped Concrete Pipe Mould Bottom Rings and Their Applications

The Importance of Stamping Concrete Pipe Mould Bottom Rings

In the realm of construction and civil engineering, the creation of durable and efficient structures relies heavily on the materials and methods used in production. One significant aspect often overlooked is the use of moulds in the manufacturing of various components. This article focuses on the stamping of concrete pipe mould bottom rings, a crucial yet understated element in the construction industry.

Concrete pipes are widely utilized for various applications, including drainage, sewage systems, and water supply. These pipes need to meet stringent quality standards to ensure they can withstand the pressures and environmental conditions they will face over their service life. The mould design plays a pivotal role in achieving this quality, and the bottom ring of a concrete pipe mould is particularly critical due to its structural and aesthetic implications.

Understanding the Concrete Pipe Mould

The concrete pipe mould consists of various components, each having its purpose. The bottom ring, as the base of the mould, is designed to support the weight of the entire pipe during the curing process. It also determines the final shape and dimensions of the pipe, making the quality of the bottom ring paramount.

Stamping is a manufacturing process that involves the use of dies to impart specific shapes and details to materials, in this case, concrete. The stamping of concrete pipe mould bottom rings allows for enhanced precision and consistency, ensuring that each ring produced is identical and meets the intended specifications.

Benefits of Stamping Mould Bottom Rings

1. Precision and Consistency Stamped moulds provide high levels of accuracy. This consistency is crucial in large-scale projects where uniformity in component sizes can significantly impact the overall structural integrity of the installation.

stamping concrete pipe mould bottom ring

2. Time Efficiency The stamping process is faster compared to traditional moulding methods. This efficiency translates to reduced production times, allowing manufacturers to meet project deadlines without compromising on quality.

3. Improved Surface Finish Stamping can enhance the surface quality of the concrete pipe bottom rings. A smooth finish reduces the likelihood of defects and can improve the binding and sealing with other construction elements.

4. Cost-Effectiveness While the initial investment in stamping technology may be higher, the long-term savings due to reduced labor costs and increased production rates can make it a financially sound decision for manufacturers.

5. Enhanced Durability Stamped moulds can produce bottom rings with better structural integrity. This leads to longer-lasting components, reducing the need for maintenance and replacement.

Conclusion

The stamping of concrete pipe mould bottom rings is an essential practice in the construction industry that offers numerous benefits in terms of precision, efficiency, and cost-effectiveness. As infrastructure demands increase globally, the need for reliable and durable concrete components becomes ever more critical. By investing in modern stamping technologies, manufacturers can not only meet these demands but also contribute to the overall enhancement of construction quality and safety.

In summary, the humble bottom ring in the concrete pipe mould may not receive the recognition it deserves, but its role is pivotal in ensuring the effectiveness and longevity of concrete pipes. Emphasizing advanced manufacturing techniques like stamping will play a vital role in shaping the future of civil engineering and construction practices.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025