- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 10, 2024 17:40 Back to list

Steel Casting Solutions for Mining Machinery and Equipment Durability and Performance

The Importance of Steel Casting in Mining Machinery

Mining is an essential industry that offers vital resources indispensable for various sectors, including construction, manufacturing, and energy. At the core of effective mining operations lies the machinery that empowers the extraction of minerals from the earth. An integral component of this machinery is steel castings, which play a pivotal role in ensuring the durability, efficiency, and safety of mining equipment.

Understanding Steel Casting

Steel casting is a manufacturing process that involves pouring molten steel into molds to create specific shapes and components used in various applications, including mining machinery. The process begins by heating steel to its melting point, followed by its transition into a liquid form. This molten steel is then poured into precisely designed molds, where it solidifies into the desired component. This process allows for a high degree of complexity and precision, making it ideal for producing parts that need to withstand heavy use and harsh environments.

Durability and Strength

One of the primary reasons why steel castings are extensively used in mining machinery is their exceptional strength and durability. Mining operations often occur in rugged terrains and harsher environments where equipment is subject to extreme stress and wear. Steel castings can endure the rigors of heavy loads, high impact forces, and abrasive materials, making them ideal for components such as buckets, frames, and other load-bearing parts of mining machinery.

Moreover, steel castings offer superior resistance to deformation compared to other materials. They maintain their structural integrity even under the pressure of significant operational demands, thereby extending the lifespan of mining machinery and reducing the frequency of replacements.

Customization and Versatility

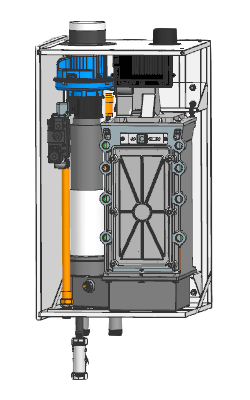

mining machinery steel casting

Another key advantage of steel casting lies in its ability to be customized for specific applications. Mining operations differ greatly in terms of the minerals being extracted, the geological conditions, and the type of machinery used. Steel castings can be tailored to meet the unique demands of each mining project, ensuring that the equipment operates efficiently, reducing downtime, and enhancing productivity.

The versatility of steel casting also allows for the integration of various design features that improve the performance of mining machinery. Manufacturers can incorporate elements such as wear-resistant coatings, improved geometry, and specific heat treatments to optimize the functionality of cast components. This capability enables mining companies to adopt advanced technologies and innovative designs that can lead to greater operational efficiency.

Safety Considerations

Safety is paramount in mining operations, where the stakes are high, and the environment can be hazardous. Steel castings contribute to safety by ensuring that machinery operates reliably without failures that could lead to accidents. Components made from high-quality steel casting undergo rigorous testing and quality control, ensuring that they meet industry standards and regulations.

Additionally, the use of steel castings in safety-critical components helps mitigate the risks associated with equipment failure. For instance, castings used in crucial mechanisms, such as load-bearing frames and support structures, are engineered to handle extreme conditions, reducing the likelihood of catastrophic breakdowns.

Conclusion

In conclusion, steel casting plays a vital role in the mining sector by providing high-strength, durable, and customizable components that enhance the performance and safety of mining machinery. The adaptability and robust nature of steel castings not only enable effective mining operations but also contribute to the overall longevity of the equipment. As technology continues to evolve, we can expect further innovations in steel casting that will enhance the reliability and efficiency of mining machinery, ultimately driving the industry forward.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025