- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 20, 2024 05:56 Back to list

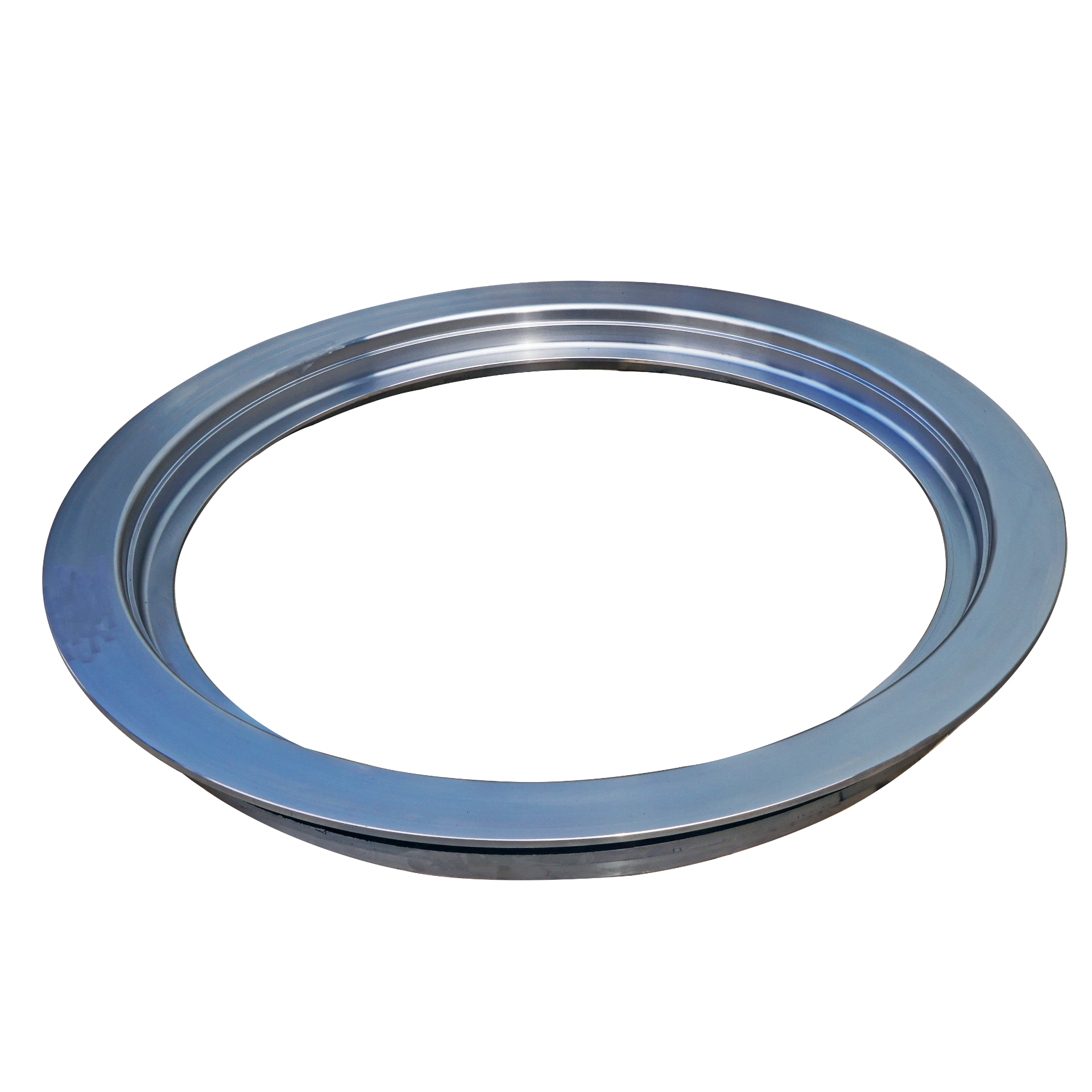

odm carbon steel casting

Understanding ODM Carbon Steel Casting A Comprehensive Overview

In the realm of manufacturing, the process of casting has proven to be a cornerstone for producing complex and durable components. Among various materials used for casting, carbon steel stands out due to its combination of strength, ductility, and versatility. One specific approach within this sector is the use of Original Design Manufacturer (ODM) services that specialize in carbon steel casting. This article explores the significance and advantages of ODM carbon steel casting.

What is ODM Carbon Steel Casting?

Original Design Manufacturer (ODM) refers to a company that designs and manufactures a product according to another company’s specifications while retaining the responsibility for production and quality. When applied to carbon steel casting, an ODM provider possesses the expertise to create customized cast iron products to meet specific requirements. This can range from automotive parts to industrial machinery components, emphasizing quality and precision.

Advantages of Carbon Steel in Casting

Carbon steel is renowned for its mechanical properties. It typically offers high tensile strength, making it an ideal material for high-stress applications. The varying carbon content in steel allows manufacturers to tailor characteristics such as hardness and ductility, making it versatile for different applications. Furthermore, carbon steel demonstrates excellent wear resistance, particularly in harsher environments, thereby extending the lifespan of components.

The ODM Advantage

odm carbon steel casting

Engaging an ODM for carbon steel casting brings several advantages to businesses. First, it significantly reduces time-to-market. As ODM providers often have established processes and technologies, companies can launch their products more swiftly compared to developing in-house capabilities from scratch. Additionally, ODMs usually have a robust understanding of the manufacturing process, which mitigates risks associated with design mistakes or production flaws.

Moreover, ODM services often provide the benefit of cost-effective production. By leveraging economies of scale, ODMs can lower manufacturing costs, resulting in savings that can be transferred to clients. This ability to provide competitive pricing without compromising quality is a crucial factor for many businesses, particularly those in price-sensitive markets.

Environmental Considerations

In today’s manufacturing landscape, sustainability has become paramount. ODM carbon steel casting companies are increasingly adopting eco-friendly practices, such as recycling scrap steel and reducing energy consumption in their processes. By focusing on sustainability, these manufacturers align their operations with global standards and consumer expectations, contributing to a more sustainable future.

Conclusion

In summary, ODM carbon steel casting not only harnesses the intrinsic benefits of carbon steel but also enhances product development timelines and cost efficiencies. As industries continue to demand innovative and durable solutions, the role of ODM providers will become even more critical. Understanding this process helps businesses to make informed decisions, fostering partnerships that can lead to both improved product offerings and market competitiveness. Whether in automotive manufacturing, heavy machinery, or custom parts production, ODM carbon steel casting will remain a vital element in the industrial landscape.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025