- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 18, 2024 08:01 Back to list

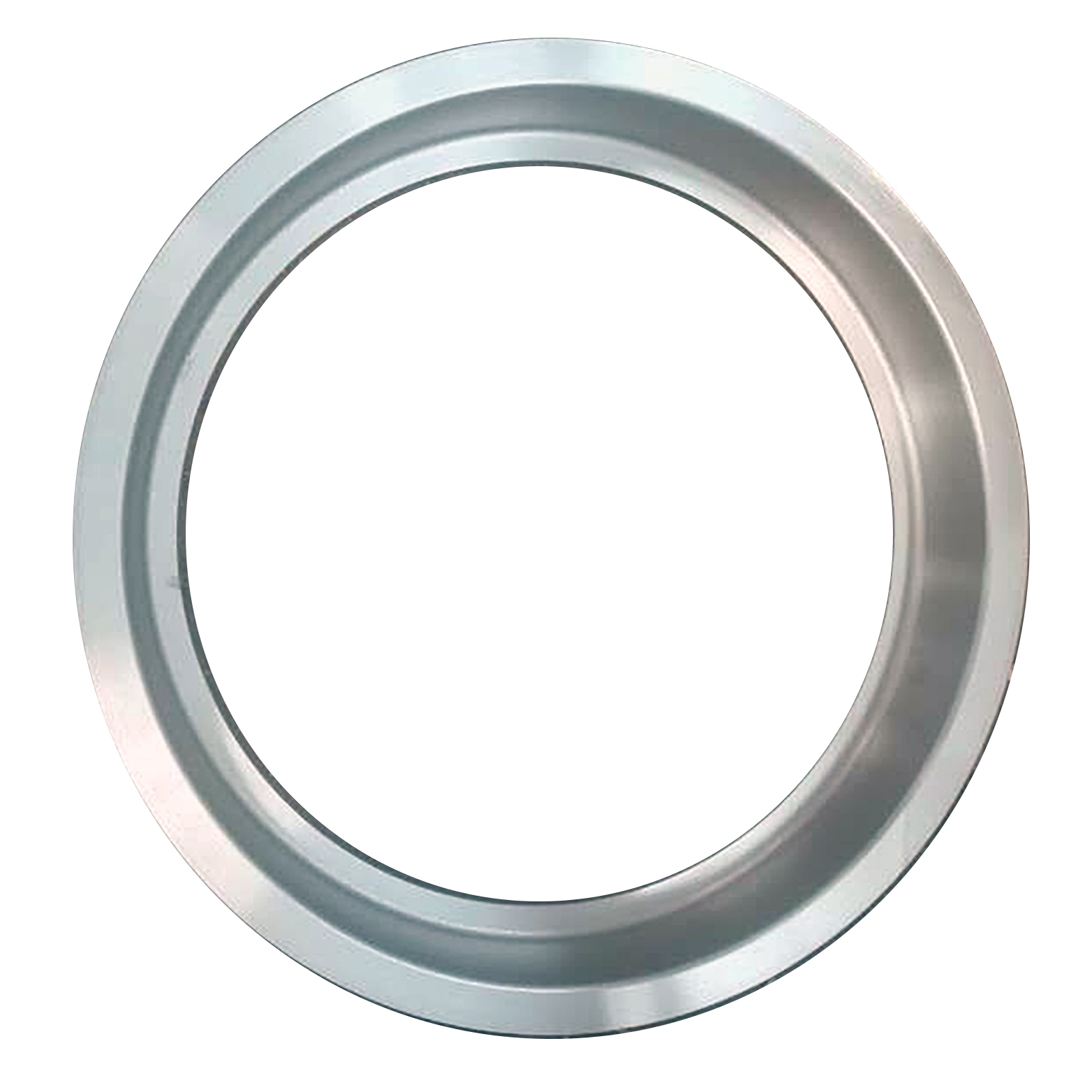

Efficient ODM Cast Iron Pipe Mold Pallet Solutions for Your Manufacturing Needs

The Importance of ODM Cast Iron Pipe Mold Pallets in Modern Manufacturing

In the manufacturing industry, the efficiency and effectiveness of production processes are paramount. One crucial element that plays a significant role in this is the use of specialized equipment, such as ODM cast iron pipe mold pallets. These pallets are integral to the casting process, providing stability and support to mold designs, especially in the production of cast iron pipes.

What Are ODM Cast Iron Pipe Mold Pallets?

ODM stands for Original Design Manufacturer, and it emphasizes the capability of creating bespoke designs tailored to specific manufacturing needs. Cast iron pipe mold pallets are designed to hold molds securely during the casting process. They are typically made from high-quality cast iron, enabling them to withstand the immense pressures and temperatures involved in casting operations. These pallets not only support the mold but also ensure that the final product maintains its shape and structural integrity throughout the manufacturing process.

Advantages of Using Cast Iron Pipe Mold Pallets

1. Durability and Strength Cast iron is known for its durability. Mold pallets made from this material can endure the high stress and abrasive nature of the casting process without warping or breaking. This longevity reduces the need for frequent replacements, leading to cost savings in the long term.

2. Precision Engineering ODM cast iron pipe mold pallets are engineered with precision to meet the specific requirements of different casting applications. This customization ensures that the molds fit perfectly and operate seamlessly, enhancing the overall quality of the cast products. The precision in design minimizes discrepancies and defects in the final pipes.

3. Thermal Stability During the casting process, temperatures can soar to thousands of degrees. Cast iron has excellent thermal stability, allowing it to maintain its structural integrity even under extreme heat. This characteristic ensures that the mold pallets can be reused multiple times without significant degradation, making them a sustainable choice.

4. Enhanced Productivity With their robust design and reliability, ODM cast iron pipe mold pallets contribute to increased productivity. They allow for quicker mold changes and setup times, enabling manufacturers to operate at higher volumes and meet market demands more effectively.

odm cast iron pipe mold pallet

5. Reduced Maintenance Costs The durability of cast iron mold pallets means they require less maintenance compared to alternatives made from other materials. Manufacturers can save on both labor and materials since there’s less need for repairs or replacements.

Applications in the Industry

ODM cast iron pipe mold pallets are used extensively in the plumbing, sewerage, and construction industries. The production of cast iron pipes is vital for infrastructure development, and thus, the equipment used must meet the highest standards of performance. These pallets ensure that pipes produced are not only robust but also meet regulatory standards for safety and reliability.

In addition to pipes, these pallets can also be utilized for casting other structures, such as fittings and connectors, which are essential in various construction applications. Their versatility makes them an invaluable asset in any foundry that specializes in cast iron products.

Future Trends

As industries evolve and the demand for efficient, high-quality products increases, the importance of ODM cast iron pipe mold pallets is only set to rise. The integration of advanced technologies, such as automation and digital manufacturing processes, may further enhance the capabilities of these mold pallets. Manufacturers are likely to explore new materials and innovative designs that can improve performance while maintaining the core benefits that cast iron offers.

Moreover, sustainability in manufacturing is becoming a focal point. Future developments may include the use of recycled materials in the production of cast iron pipe mold pallets, reducing environmental impact while ensuring top-tier performance.

Conclusion

In summary, ODM cast iron pipe mold pallets are a critical component in the manufacturing of cast iron pipes, offering an array of advantages, including durability, precision, and cost-effectiveness. As the industry continues to progress, the role of these pallets will become increasingly significant, underpinning the efficiency of production processes and the quality of the final products. The future of manufacturing relies on such innovative solutions, ensuring that industries can meet the challenges of tomorrow head-on.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025