- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 23, 2024 05:00 Back to list

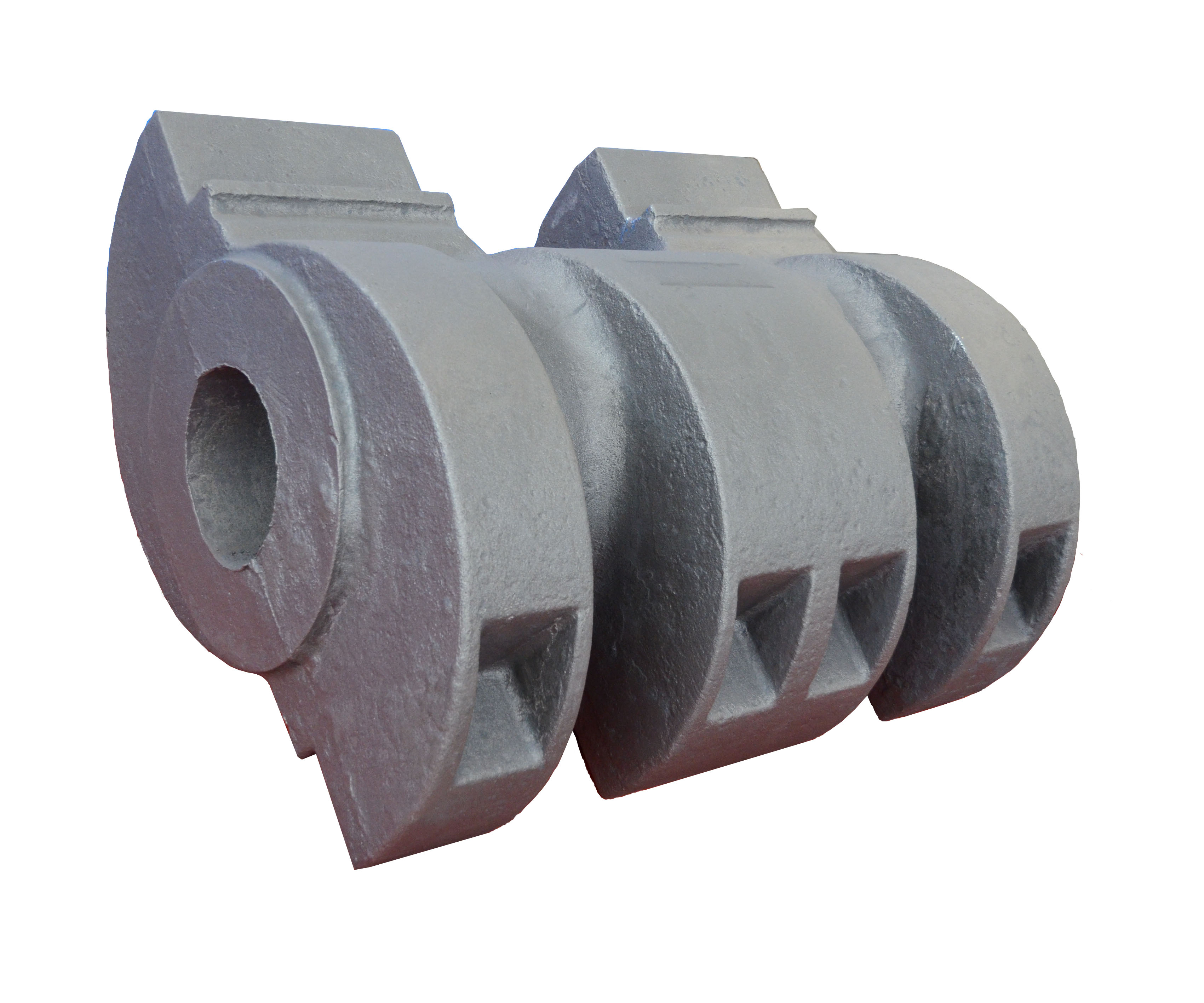

odm cast silicon aluminum alloy heat exchanger

The Emergence of ODM Cast Silicon Aluminum Alloy Heat Exchangers

In recent years, the demand for efficient thermal management solutions across various industries has surged, driven by advancements in technology and the increasing need for sustainable energy solutions. Among these innovations, ODM (Original Design Manufacturer) cast silicon aluminum alloy heat exchangers have emerged as a compelling option, combining lightweight properties, excellent thermal conductivity, and resistance to corrosion. This article delves into the attributes and applications of this innovative material in heat exchanger design.

Silicon aluminum alloys are distinguished by their unique combination of aluminum and silicon, which grants them superior casting properties and enhances their thermal performance. The alloy’s low density not only contributes to weight reduction in components but also improves the overall system's efficiency. Consequently, ODM cast silicon aluminum alloy heat exchangers are becoming increasingly favored in sectors such as automotive, aerospace, and renewable energy systems.

One of the standout features of silicon aluminum alloys is their excellent thermal conductivity. This property is crucial for heat exchangers, which are designed to transfer thermal energy between two or more fluids. High thermal conductivity ensures that heat is transferred efficiently, reducing the energy required to maintain desired temperatures within a system. As energy efficiency becomes paramount in modern design, ODM cast silicon aluminum alloy heat exchangers provide an effective solution, optimizing performance without compromising on space or weight.

odm cast silicon aluminum alloy heat exchanger

Moreover, these heat exchangers exhibit remarkable resistance to corrosion. Corrosion can significantly reduce the lifespan of traditional metal heat exchangers, leading to increased maintenance costs and system inefficiencies. The inherent properties of silicon aluminum alloys, however, provide resilience against various corrosive environments, thereby extending the service life of exchangers in challenging conditions.

The manufacturing process of ODM cast silicon aluminum alloy heat exchangers is another reason for their rising popularity. The ODM model allows for custom designs tailored to specific application needs, making it an ideal choice for manufacturers seeking unique solutions. Advanced casting technologies enable the production of complex geometries that can enhance the thermal performance of the heat exchangers while ensuring uniform material properties throughout the component. This capability is particularly beneficial in industries like automotive, where compact and efficient designs are essential.

The applications of ODM cast silicon aluminum alloy heat exchangers are diverse. In the automotive industry, they can be utilized in engine cooling systems, fuel cooling applications, and HVAC systems, where weight savings and efficiency are critical. In the aerospace sector, these heat exchangers contribute to the thermal control systems of aircraft, ensuring optimal performance at various altitudes and environmental conditions. Furthermore, renewable energy systems, such as solar thermal systems and geothermal applications, benefit from the lightweight design and efficient thermal transfer capabilities of these heat exchangers.

In conclusion, ODM cast silicon aluminum alloy heat exchangers represent a significant leap forward in thermal management technology. Their properties—lightweight, excellent thermal conductivity, resistance to corrosion, and customization options—position them as highly advantageous in various industries. As the global emphasis on efficiency and sustainability continues to grow, the adoption of such innovative materials will undoubtedly play a key role in enhancing thermal management solutions, contributing to a more sustainable future.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025