- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 11, 2024 00:51 Back to list

Concrete Pipe Mold and Bottom Ring for ODM Applications

The Importance of ODM Concrete and Cement Pipe Molds

In the rapidly evolving construction industry, the demand for durable and efficient building materials is at an all-time high. Among these materials, concrete and cement pipes play crucial roles in infrastructure development, particularly in drainage, sewage, and water supply systems. To ensure the quality and consistency of these pipes, the use of specialized molds, such as the ODM concrete and cement pipe molds, is essential.

Understanding ODM Concrete and Cement Pipe Molds

ODM, or Original Design Manufacturer, refers to companies that design and produce products based on specifications provided by another company. In the context of concrete and cement pipe manufacturing, ODM molds represent bespoke solutions tailored to meet specific client needs, enhancing production efficiency and product quality.

These molds are crafted using high-quality materials designed to withstand the intense pressures associated with concrete curing processes. They are engineered to create pipes of varying diameters and layouts, catering to diverse construction requirements. The ability to produce a wide range of products is vital for manufacturers aiming to serve different segments of the market.

Features of ODM Concrete and Cement Pipe Molds

One of the standout features of ODM molds is their customizable nature. Manufacturers can specify dimensions, ring designs, and configurations to create molds that fit their precise needs. This flexibility helps in reducing waste and increasing efficiency in the production process.

Moreover, ODM molds often come with enhanced functionalities, such as easy demolding systems, which facilitate quick removal of finished products. This feature not only expedites the manufacturing process but also minimizes potential damage to the pipes during extraction.

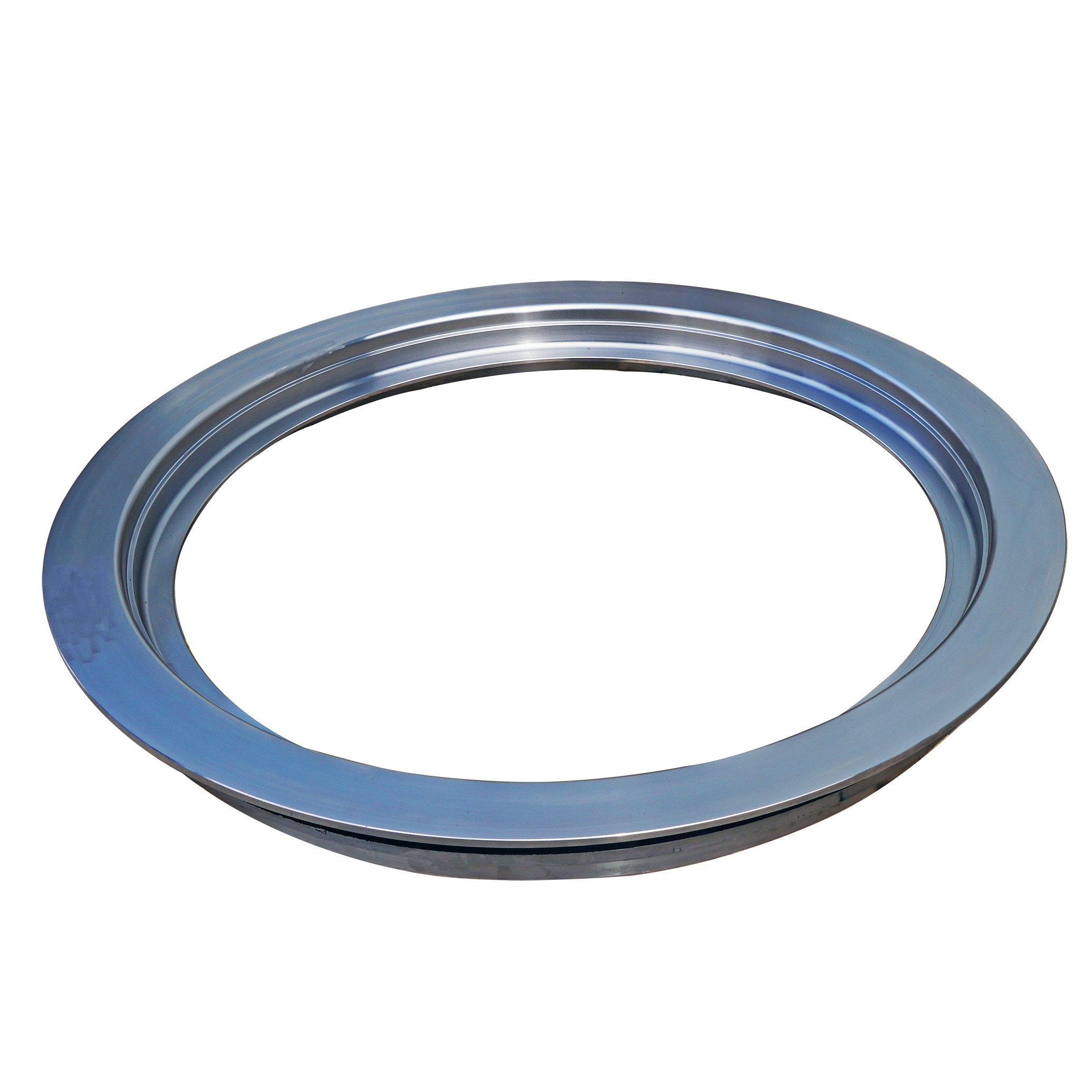

odm concrete/cement pipe mold/mould bottom ring

Another critical benefit is the durability of the molds. Constructed from high-grade materials such as steel and reinforced composites, ODM molds are resistant to corrosion and wear, ensuring they maintain their shape and performance over time. This longevity translates to lower replacement costs and increased productivity for manufacturers.

The Role of Mould Bottom Rings

An integral part of the ODM mold system is the bottom ring. The bottom ring provides structural support during the casting process and ensures uniformity in the pipe’s base, which is essential for load distribution. Without a reliable bottom ring, the integrity of the concrete pipe could be compromised, leading to issues such as cracking or deformation.

The design of the bottom ring is crucial; it must provide a secure fit while allowing for the seamless flow of concrete during filling. Modern technological advancements have led to the development of bottom rings that include features such as vibration absorption systems, further enhancing the quality of the finished product.

Conclusion

In summary, ODM concrete and cement pipe molds, along with their essential components like bottom rings, play a vital role in the construction industry. Their adaptability, durability, and efficient design contribute to the production of high-quality concrete pipes. As the demand for reliable infrastructure continues to grow, the importance of these molds will only increase.

Manufacturers looking to thrive in this competitive market must embrace the advancements in ODM mold technology to enhance their production capabilities. By investing in high-quality concrete and cement pipe molds, they can deliver superior products that meet the rigorous standards of today’s construction projects, ultimately contributing to the development of robust infrastructure worldwide.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025