- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 27, 2024 21:10 Back to list

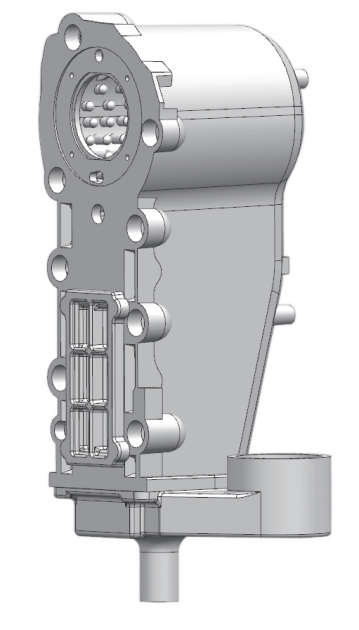

OEM Concrete Pipe Mold with Mould Bottom Ring for Efficient Cement Production Solutions

Understanding OEM Concrete and Cement Pipe Molds The Importance of Mould Bottom Rings

In the construction and manufacturing industries, particularly in the production of concrete and cement products, the importance of precision and efficiency cannot be overstated. One crucial component that plays a significant role in this process is the mold, especially the bottom ring of the mould used in the fabrication of concrete and cement pipes. Original Equipment Manufacturer (OEM) practices in this sector ensure that manufacturers produce high-quality, standardized components that meet international specifications.

What Are OEM Concrete and Cement Pipe Molds?

OEM molds are custom-made designs produced for specific manufacturers and are integral to making concrete and cement pipes. These molds are designed to ensure that pipes are formed correctly, maintaining the desired dimensions, shape, and structural integrity. The manufacturing process for these molds involves high precision engineering, often utilizing robust materials capable of withstanding the heavy pressure during the curing of concrete.

The significance of using OEM molds lies in their ability to streamline production processes. When manufacturers rely on OEM molds, they benefit from enhanced quality control, reduced production costs, and improved turnaround times. This advantage becomes particularly evident in large-scale production, where consistency and reliability are paramount.

The Role of Mould Bottom Rings

Among the various components of a concrete or cement pipe mold, the bottom ring is a critical feature that demands attention. The bottom ring serves as the foundation of the mold, providing stability and support while the concrete is poured and sets. Its design and construction can substantially affect the quality of the final product.

The bottom ring not only helps maintain the shape during the curing process, but it also influences the drainage of excess water. Proper drainage is essential for preventing defects in the concrete, such as cracks or uneven surfaces. A well-engineered bottom ring ensures that the mold can withstand the immense weight of wet concrete and maintains the integrity of the structure as it cures.

Benefits of Using High-Quality Bottom Rings

oem concrete/cement pipe mold/mould bottom ring

Investing in high-quality bottom rings for concrete and cement pipe molds has several advantages

1. Durability High-quality materials and manufacturing techniques extend the lifespan of the bottom rings, reducing the need for frequent replacements and repairs.

2. Precision Accurate dimensions ensure that the pipes produced meet industry standards, which is crucial for applications in plumbing, sewerage, and construction.

3. Reduced Defects By ensuring proper drainage and structural integrity during the curing process, high-quality bottom rings minimize the risk of defects, leading to a higher overall yield of usable products.

4. Cost Efficiency While there may be a higher initial investment in quality molds and components, the long-term savings from reduced waste, maintenance, and increased productivity considerably outweigh the upfront costs.

Conclusion

As the demand for concrete and cement products continues to grow, the role of OEM molds, particularly the bottom rings, becomes increasingly vital. They form the backbone of an efficient production process, ensuring that the end products meet the required standards of quality and performance.

Manufacturers looking to enhance their production capabilities should consider the integration of high-quality OEM molds into their operations. By focusing on the design and manufacturing of components like the mould bottom ring, they set the stage for sustainable practices, greater reliability, and a solid reputation in the market. Ultimately, investing in these critical components will yield substantial returns in quality, efficiency, and profitability for businesses in the concrete and cement manufacturing industry.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025