- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 04, 2024 10:19 Back to list

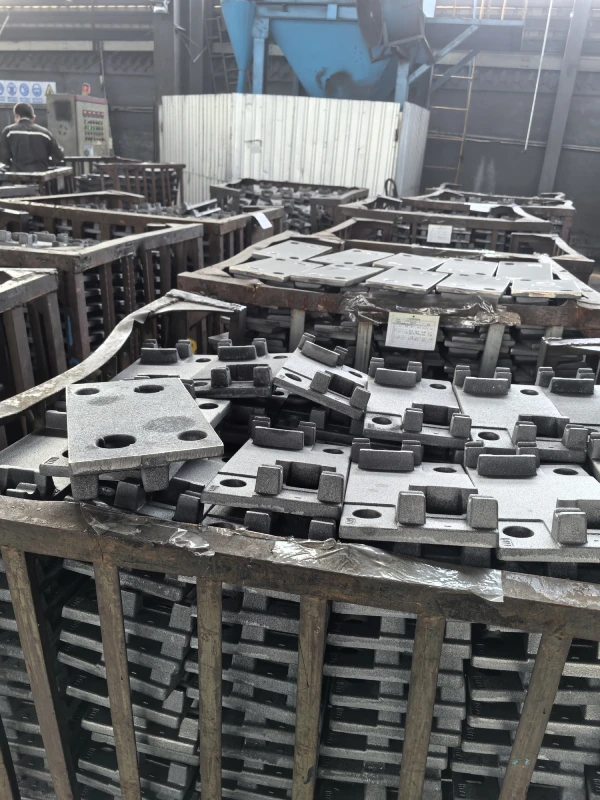

oem casting product

The Importance of OEM Casting Products in Modern Manufacturing

In today’s rapidly evolving industrial landscape, Original Equipment Manufacturer (OEM) casting products play a crucial role across various sectors, from automotive and aerospace to consumer goods and machinery. The term OEM refers to companies that produce products or components that are then marketed by another company under its brand. Casting, a manufacturing process that involves pouring liquid material into a mold to solidify and create intricate shapes, is vital to the production of high-quality OEM components.

Advantages of OEM Casting Products

One significant advantage of using OEM casting products is the ability to achieve high precision and complexity in design. Advanced casting techniques, such as sand casting, investment casting, and die casting, allow manufacturers to produce intricate and detailed components with tight tolerances. This precision is especially important in industries like aerospace, where even a minor flaw can impact safety and performance.

Another benefit of OEM casting is the material versatility it offers. Manufacturers can use a variety of metals and alloys, including aluminum, steel, iron, and more specialized materials like magnesium and titanium. This flexibility allows OEMs to select the best material for their product needs, ensuring optimal performance, durability, and cost-effectiveness.

Enhancing Efficiency Through OEM Partnerships

The collaboration between OEMs and casting manufacturers can significantly enhance overall production efficiency. By outsourcing casting operations to specialized suppliers, OEMs can focus on their core competencies, such as design, assembly, and marketing. This division of labor not only optimizes resource allocation but also enables faster turnaround times for product development and manufacturing.

Moreover, established casting suppliers often have the experience and expertise to implement efficient processes and quality control measures. They leverage advanced technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), and robotics to streamline the manufacturing process. As a result, OEMs can benefit from reduced waste, lower production costs, and improved product quality.

oem casting product

Innovation and Sustainability

The landscape of OEM casting is also changing with an increasing emphasis on innovation and sustainability. As industries face more stringent environmental regulations and consumer demand for eco-friendly products rises, manufacturers are looking for ways to minimize their environmental footprint. Many casting manufacturers are adopting sustainable practices, such as recycling sand and molten metal, utilizing energy-efficient equipment, and implementing waste reduction strategies.

Furthermore, advancements in technology, such as additive manufacturing and 3D printing, are reshaping the casting process. These innovations allow for even greater design freedom, shorter lead times, and the production of complex geometries that were previously impossible. Incorporating these technologies into OEM casting can result in lighter, stronger, and more efficient parts, ultimately leading to better-performing end products.

Challenges in the OEM Casting Sector

Despite the advantages, the OEM casting sector faces challenges that must be addressed to maintain competitiveness. Fluctuating raw material prices, global supply chain disruptions, and the need for consistent product quality can hinder production. Additionally, with the rise of globalization, OEMs must navigate various regulations and standards in different markets, which can complicate the manufacturing process.

To stay ahead in this competitive landscape, OEMs and casting suppliers must prioritize collaboration and communication. By developing long-term partnerships and investing in R&D, they can innovate and adapt to changing market demands. Continuous improvement processes, such as Lean and Six Sigma methodologies, can also help enhance efficiency and reduce defects.

Conclusion

In conclusion, OEM casting products are integral to the modern manufacturing ecosystem, offering numerous advantages in precision, material choice, and efficiency. As industries continue to evolve, the focus on innovation and sustainability will shape the future of OEM casting. By addressing current challenges and leveraging the latest technologies, OEMs can not only enhance their product offerings but also contribute to a more sustainable and efficient manufacturing landscape. Ultimately, the success of OEM casting lies in collaboration, innovation, and a commitment to quality, positioning it as a cornerstone of modern industry.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025