- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 08, 2024 04:54 Back to list

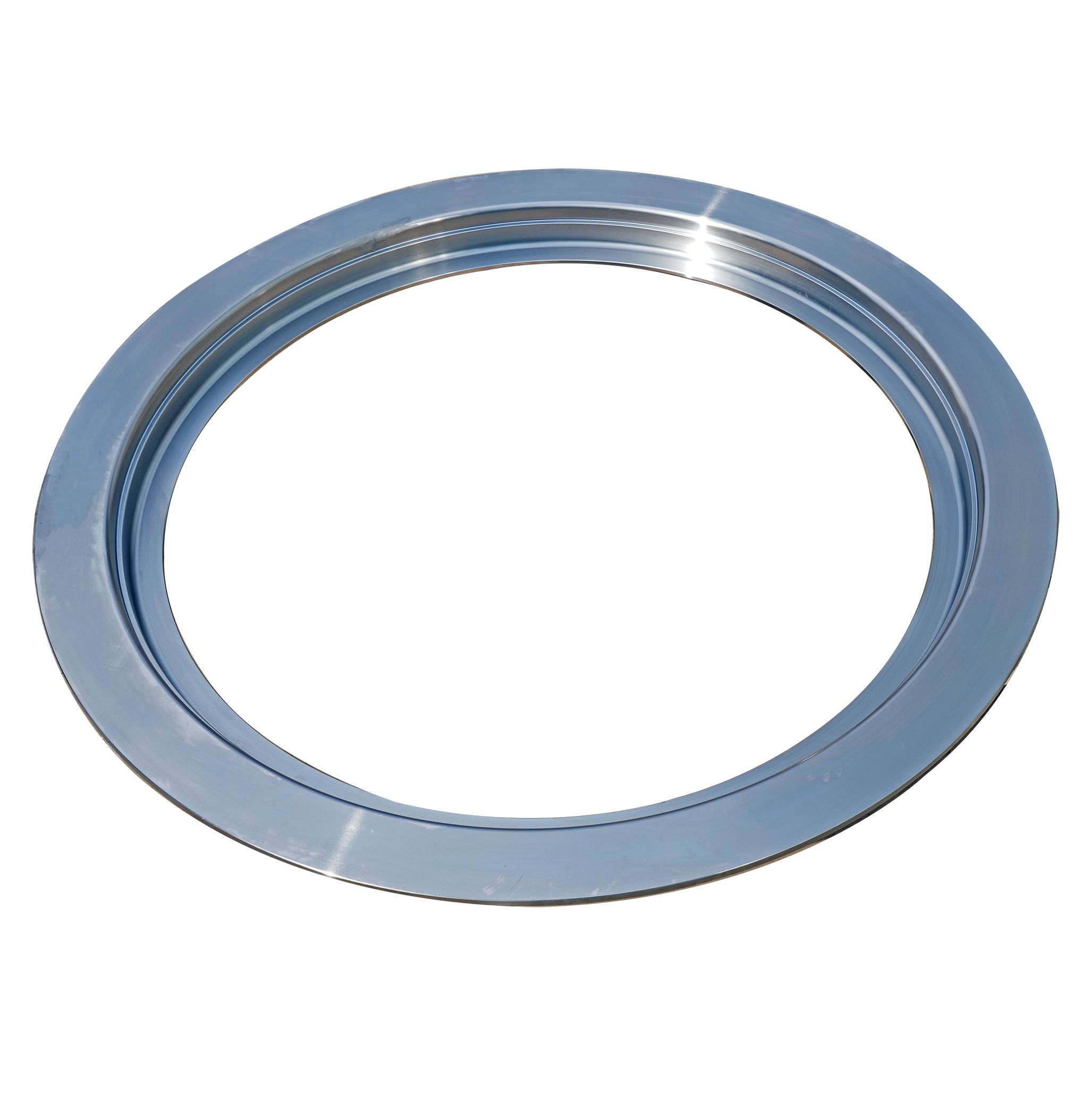

OEM Cast Steel Pipe Mold Base Ring Fabrication Solutions for Industrial Applications

The Importance of OEM Cast Steel Pipe Mold Bottom Rings in Manufacturing

In today's highly competitive manufacturing environment, the efficiency and effectiveness of production processes are paramount. One critical component that plays a significant role in ensuring smooth operations is the OEM cast steel pipe mold bottom ring. This specialized component is essential for industries that rely on the production of steel pipes, such as construction, automotive, and oil & gas. Understanding its functionality, benefits, and applications can provide valuable insight into why it is an indispensable part of the manufacturing process.

What is an OEM Cast Steel Pipe Mold Bottom Ring?

An OEM (Original Equipment Manufacturer) cast steel pipe mold bottom ring is a precision-engineered component designed for use in the casting process of steel pipes. The primary function of the bottom ring is to support the mold during the casting operation, ensuring that the shape and structural integrity of the pipe are maintained. Designed specifically for casting applications, these rings are manufactured from high-quality steel, which provides the necessary strength, durability, and resistance to thermal and mechanical stresses encountered during the casting process.

The Manufacturing Process From Design to Production

The creation of an OEM cast steel pipe mold bottom ring involves several steps. Initially, it begins with precise design specifications, which take into account the dimensions, weight tolerance, and material properties required for optimal performance. Modern CAD software is often employed to create detailed 3D models, ensuring that the manufacturing process will yield components that meet the stringent standards of various industries.

Once the design has been finalized, the next step is the casting process. High-quality steel is melted and poured into molds shaped according to the specified design. The casting is then allowed to cool and solidify, forming a robust bottom ring. After the initial casting, the rings undergo various finishing processes, including machining, surface treatment, and quality checks. These steps are crucial for removing any imperfections and ensuring that the rings meet the strict quality standards required for OEM products.

Benefits of Using OEM Cast Steel Pipe Mold Bottom Rings

oem cast steel pipe mold bottom ring

1. Durability and Longevity One of the main advantages of OEM cast steel pipe mold bottom rings is their durability. Made of high-quality steel, these rings can withstand the extreme conditions of the casting process, including high temperatures and mechanical forces. This durability leads to a longer lifespan and fewer replacements, which ultimately reduces operational costs.

2. Precision Engineering OEM components are manufactured to precise specifications, ensuring a perfect fit with the molds used in the casting process. This precision minimizes defects in the final product, leading to higher quality steel pipes that meet industry standards.

3. Customized Solutions OEM manufacturers often provide custom solutions tailored to the specific needs of their clients. This flexibility means that industries can receive bottom rings designed for specific use cases, enhancing productivity and efficiency.

4. Cost-Effectiveness While the initial investment in OEM cast steel pipe mold bottom rings may be higher than generic alternatives, their long-term benefits often outweigh the costs. The reliability, reduced downtime, and enhanced product quality can lead to significant savings over time.

Applications Across Industries

The application of OEM cast steel pipe mold bottom rings is extensive. In the construction industry, they are vital for producing high-quality steel pipes used in infrastructure projects. In the automotive sector, these pipes form essential components of vehicle systems. The oil & gas industry also relies heavily on steel pipes for transporting crude oil and natural gas, making the importance of durable and precise mold bottom rings even more pronounced.

Conclusion

In conclusion, OEM cast steel pipe mold bottom rings are crucial components in the steel manufacturing process. Their durability, precision, and potential for customization make them an excellent investment for industries that require efficient and effective casting operations. By understanding their importance and functionality, manufacturers can leverage these components to enhance their production capabilities, reduce costs, and improve product quality. As industries continue to evolve, the significance of these components will only grow, underscoring the need for innovative manufacturing solutions.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025