- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 23, 2024 04:05 Back to list

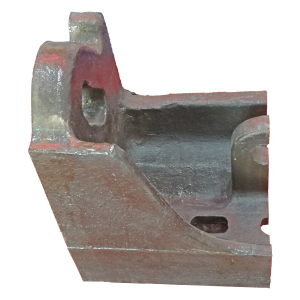

oem gas fired boiler made from cast silico aluminum heat exchanger

The Evolution of OEM Gas-Fired Boilers A Focus on Cast Silicon Aluminum Heat Exchangers

In the modern era of energy efficiency and sustainable practices, the demand for advanced heating solutions has never been more pressing. Among these innovations, OEM (Original Equipment Manufacturer) gas-fired boilers have emerged as a reliable and effective option for both residential and industrial applications. One of the key components driving the efficiency and performance of these boilers is the use of cast silicon aluminum heat exchangers, a technology that is revolutionizing the heating industry.

Gas-fired boilers operate by burning natural gas to generate heat, which is then transferred through a heat exchanger to water or air for heating purposes. The heat exchanger itself is crucial, as it determines how efficiently heat is transferred and how much energy is wasted in the process. Traditional heat exchangers were primarily made from steel, but recent advancements have led to the utilization of cast silicon aluminum, a material that offers several significant benefits.

One of the most notable advantages of cast silicon aluminum heat exchangers is their excellent thermal conductivity. When compared to traditional materials, aluminum boasts superior heat transfer properties, allowing these exchangers to operate more efficiently. This means that OEM gas-fired boilers equipped with aluminum heat exchangers can heat water more quickly and maintain higher temperatures, resulting in improved overall performance and reduced energy consumption. In an era where energy costs are on the rise, this efficiency translates into real savings for consumers.

Durability is another critical factor that makes cast silicon aluminum an ideal choice for heat exchangers. Cast silicon aluminum exhibits remarkable resistance to corrosion, which is particularly important in environments where the heat exchanger is exposed to moisture and other elements. This durability extends the lifespan of the heat exchanger, reducing the need for replacements and maintenance. For OEMs, this not only helps in lowering production costs but also enhances the value proposition offered to customers.

oem gas fired boiler made from cast silico aluminum heat exchanger

The lightweight nature of aluminum compared to traditional cast iron or steel is another advantage that cannot be overlooked. The reduced weight of cast silicon aluminum heat exchangers contributes to easier installation and transportation, making it a favorite among manufacturers and installers alike. This flexibility allows for a broader application of gas-fired boilers across different sectors, from residential homes to large industrial facilities.

Moreover, advancements in manufacturing processes have enabled the production of intricate designs using cast silicon aluminum, leading to more efficient heat exchanger configurations. This innovation facilitates increased surface area for heat transfer without compromising the structural integrity of the unit. As a result, OEM gas-fired boilers are becoming smaller and more compact while still providing high output levels.

Environmental considerations are also driving the shift towards gas-fired boilers with cast silicon aluminum heat exchangers. As governments and organizations worldwide strive to reduce carbon footprints and move towards greener solutions, these boilers represent a significant advancement. By maximizing energy efficiency and minimizing emissions, they provide a cleaner alternative to traditional heating methods, aligning with global sustainability goals.

Finally, the competitive market for OEM gas-fired boilers has pushed manufacturers to continuously innovate and improve their offerings. The integration of cast silicon aluminum heat exchangers reflects a broader trend towards high-performance, energy-efficient systems that meet the evolving needs of consumers.

In conclusion, OEM gas-fired boilers with cast silicon aluminum heat exchangers are at the forefront of heating technology. Their combination of efficiency, durability, light weight, and environmental benefits positions them as a preferred choice for a wide range of applications. As the industry continues to evolve, these innovations will play a crucial role in shaping the future of energy solutions, ensuring that we meet our heating needs without compromising on sustainability.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025