Nov . 08, 2024 05:57 Back to list

Top Suppliers of Stainless Steel Components and Parts for Industrial Use

The Growing Demand for Stainless Steel Parts Suppliers and Their Importance

In recent years, the demand for stainless steel parts has surged across various industries, including automotive, aerospace, construction, and manufacturing. The unique properties of stainless steel—such as its corrosion resistance, durability, and aesthetic appeal—make it an ideal choice for a wide range of applications. As a result, stainless steel suppliers have become crucial players in the supply chain, catering to the needs of manufacturers seeking high-quality parts.

Understanding Stainless Steel

Stainless steel is an alloy primarily composed of iron, carbon, and a minimum of 10.5% chromium. The presence of chromium creates a passive layer of chromium oxide on the surface of the steel, preventing oxidation and corrosion. This property is particularly beneficial in environments exposed to moisture, chemicals, and varying temperatures. Other alloying elements such as nickel, molybdenum, and manganese can also be added to enhance specific characteristics like strength, ductility, and resistance to pitting.

Due to its myriad benefits, stainless steel is used in a plethora of applications, from kitchenware to industrial machinery. The automotive industry utilizes stainless steel for exhaust systems, fuel tanks, and various structural components, while the aerospace sector incorporates it in aircraft engines and structural frames.

The Role of Suppliers

Stainless steel suppliers play a pivotal role in ensuring that manufacturers have access to the raw materials they need to produce high-quality parts. These suppliers operate in various capacities, from large-scale distributors to specialized manufacturers. They source stainless steel in various forms, including sheets, bars, tubes, and customized components, based on the exact specifications of their customers.

One of the critical responsibilities of stainless steel suppliers is maintaining a consistent supply chain. Fluctuations in the market, changes in raw material availability, and geopolitical events can impact the supply of stainless steel. Therefore, suppliers must strategically manage their inventories and logistics to meet customer demands without delay.

Moreover, suppliers often provide value-added services, such as custom fabrication, machining, and surface finishing. These services allow manufacturers to streamline their production processes by offering pre-fabricated parts that are ready for assembly. This not only saves time but also reduces the overall cost of manufacturing.

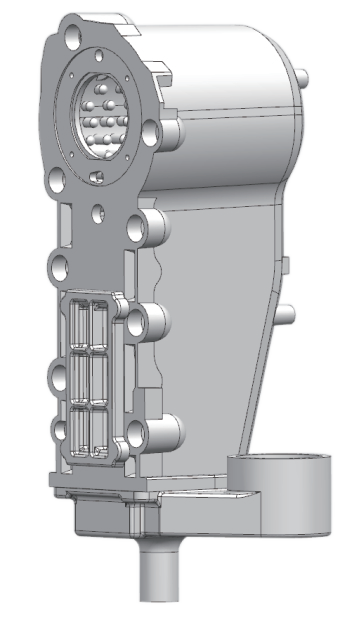

parts stainless steel suppliers

Sustainability Considerations

As industries continue to focus on sustainability and reducing their environmental impact, the demand for stainless steel is expected to increase. Stainless steel is 100% recyclable, making it an environmentally friendly choice compared to other materials. Many suppliers are now emphasizing sustainable practices in their operations, ensuring that their sourcing, production, and delivery processes align with environmentally responsible standards.

Additionally, suppliers are increasingly looking at their supply chains to identify and mitigate risks. By fostering relationships with reputable manufacturers and ensuring ethical sourcing practices, stainless steel suppliers can provide their customers with peace of mind regarding the origins of their materials.

Challenges Faced by Suppliers

Despite the growing demand, stainless steel suppliers face several challenges. Price volatility is a significant concern, as prices for raw materials can fluctuate based on global market conditions. Additionally, supply chain disruptions, such as those experienced during the COVID-19 pandemic, have highlighted the vulnerability of global trade and the need for resilient supply chains.

Furthermore, competition among suppliers is fierce. With many players in the market, suppliers must differentiate themselves by offering superior quality, customer service, and innovative solutions. Building long-term relationships with clients is essential, as repeat business can significantly impact a supplier's success.

Conclusion

In conclusion, stainless steel parts and their suppliers play a vital role in multiple industries and are essential to manufacturing and production processes. As the demand for stainless steel continues to rise, suppliers must navigate various challenges while maintaining high-quality standards and sustainable practices. By doing so, they not only ensure their survival in a competitive market but also contribute to the advancement of industries reliant on this versatile and valuable material. The future of stainless steel parts is bright, and with it, the importance of skilled and reliable suppliers will only grow.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025