Nov . 08, 2024 05:46 Back to list

Reliable Suppliers for High-Quality Stainless Steel Castings and Components

The Importance of Selecting Reliable Stainless Steel Casting Suppliers

In the manufacturing sector, stainless steel casting plays a significant role in various applications due to its durability, resistance to corrosion, and aesthetic appeal. The demand for high-quality stainless steel castings has led to a growing market of suppliers. Choosing the right stainless steel casting supplier is critical for manufacturers who aim to maintain quality and efficiency. In this article, we will explore key considerations when selecting stainless steel casting suppliers and highlight the significance of quality and reliability in this industry.

Understanding Stainless Steel Casting

Stainless steel casting is a process where molten stainless steel is poured into molds to create complex shapes and designs. This method is favored in industries such as automotive, aerospace, medical, and food processing due to its ability to produce intricate parts that are both strong and resistant to oxidation. The unique properties of stainless steel, such as its ability to withstand extreme temperatures and corrosive environments, make it a preferred choice for many applications.

Key Factors to Consider

1. Quality Control Standards One of the first factors to consider in selecting a stainless steel casting supplier is their adherence to quality control standards. Reputable suppliers often have certifications like ISO 9001, which indicates a commitment to high-quality production processes. Ensuring that the supplier follows stringent quality control measures can greatly reduce the likelihood of defects in the final product.

2. Material Specifications Different applications require different grades of stainless steel. Suppliers should be well-versed in the various types of stainless steel, such as 304, 316, and duplex stainless steels, each offering distinct advantages. It is essential to discuss your specific requirements with potential suppliers and ensure they can provide the appropriate materials for your project.

3. Customization Capabilities Many projects involve unique designs or specifications. A supplier that offers customization options can help you create tailored solutions that meet your exact needs. Ask potential suppliers about their capacity for custom molds and their experience in producing non-standard parts.

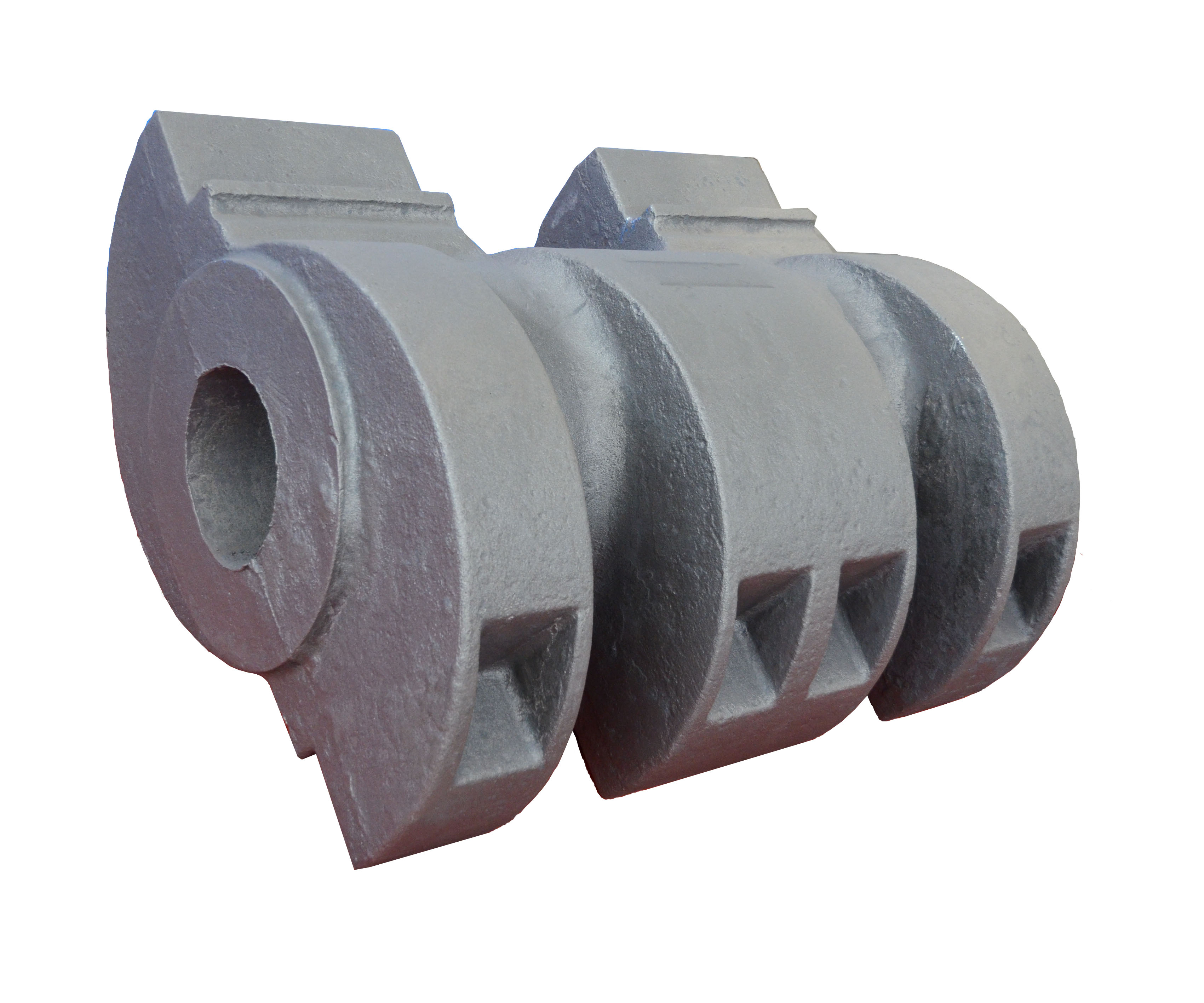

stainless steel casting suppliers

4. Technical Expertise The level of technical expertise within a company can significantly impact the quality of the final product. Look for suppliers with skilled engineers and designers who can provide guidance throughout the design and production process. A knowledgeable supplier can help troubleshoot issues early in the design phase, ensuring a smoother production process.

5. Lead Times and Delivery Timely delivery is crucial in the manufacturing industry. Investigate the lead times offered by various suppliers and their ability to meet your project timelines. A reliable supplier should provide a clear schedule and keep you informed of any potential delays.

6. Cost-effectiveness While quality should never be compromised, it is essential to consider the pricing of services. Obtain quotes from multiple suppliers, and compare not just the prices but the value offered. A cheaper option may end up costing more if it results in defects or delays in production.

7. Reputation and Experience Finally, consider the reputation and experience of potential suppliers. Look for client testimonials and case studies that highlight their successful projects. Suppliers with a proven track record in the industry will likely provide better service and quality.

Building a Long-lasting Relationship

Once you have selected a stainless steel casting supplier, it is crucial to build a solid working relationship. Open communication about expectations, timelines, and quality assurance can foster a partnership that benefits both parties. Regular check-ins and feedback can help improve the process and address any concerns before they escalate.

Conclusion

Selecting the right stainless steel casting suppliers is a vital step in ensuring the success of your manufacturing operations. By focusing on quality, customization options, technical expertise, and reputation, you can find a supplier that meets your needs and supports your project goals. As the market for stainless steel castings continues to grow, investing time and resources in building these relationships will ultimately lead to improved product quality and business success.

-

Centrifugally Cast Iron Water Main Pipe | Ductile Iron Solutions

NewsAug.24,2025

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025