- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 28, 2024 14:51 Back to list

Precision Cast Iron Casting Exporters and Their Global Impact on Industry

Precision Cast Iron Casting Exporters A Guide to Global Trade

In today's global marketplace, precision cast iron casting has emerged as a significant sector within the manufacturing industry. Known for its durability, thermal stability, and excellent machinability, cast iron is essential in various applications, from automotive parts to industrial machinery. This article explores the vital role of precision cast iron casting exporters, the benefits of their products, and the significance of this industry on a global scale.

Understanding Precision Cast Iron Casting

Precision casting, also known as lost wax casting or investment casting, is a manufacturing process that allows for intricate designs and tight tolerances. This technique ensures that the final product meets rigorous specifications, making it highly sought after in sectors that demand high-quality components. The precision cast iron casting process involves creating a wax model, encasing it in a refractory material, and then replacing the wax with molten iron, resulting in a precise cast.

The Role of Exporters in the Global Supply Chain

Exporters play a pivotal role in the availability of precision cast iron components worldwide. They bridge the gap between manufacturers in countries with surplus production capabilities, such as India, China, and the United States, and businesses in regions with growing demand, like Europe and Southeast Asia. With the expansion of global trade agreements and advancements in logistics, these exporters facilitate a smooth transaction process, ensuring that high-quality cast iron products reach various markets promptly.

Benefits of Precision Cast Iron Casting

1. Durability and Strength Precision cast iron components are known for their excellent durability and resistance to wear and tear. This makes them particularly suitable for heavy-duty applications, such as engine blocks, machine frames, and industrial tooling.

2. Cost-Effectiveness While the initial investment for precision casting might be higher than other manufacturing methods, the durability and longevity of cast iron components lead to lower overall costs. This is particularly beneficial for industries where replacement parts are frequently needed.

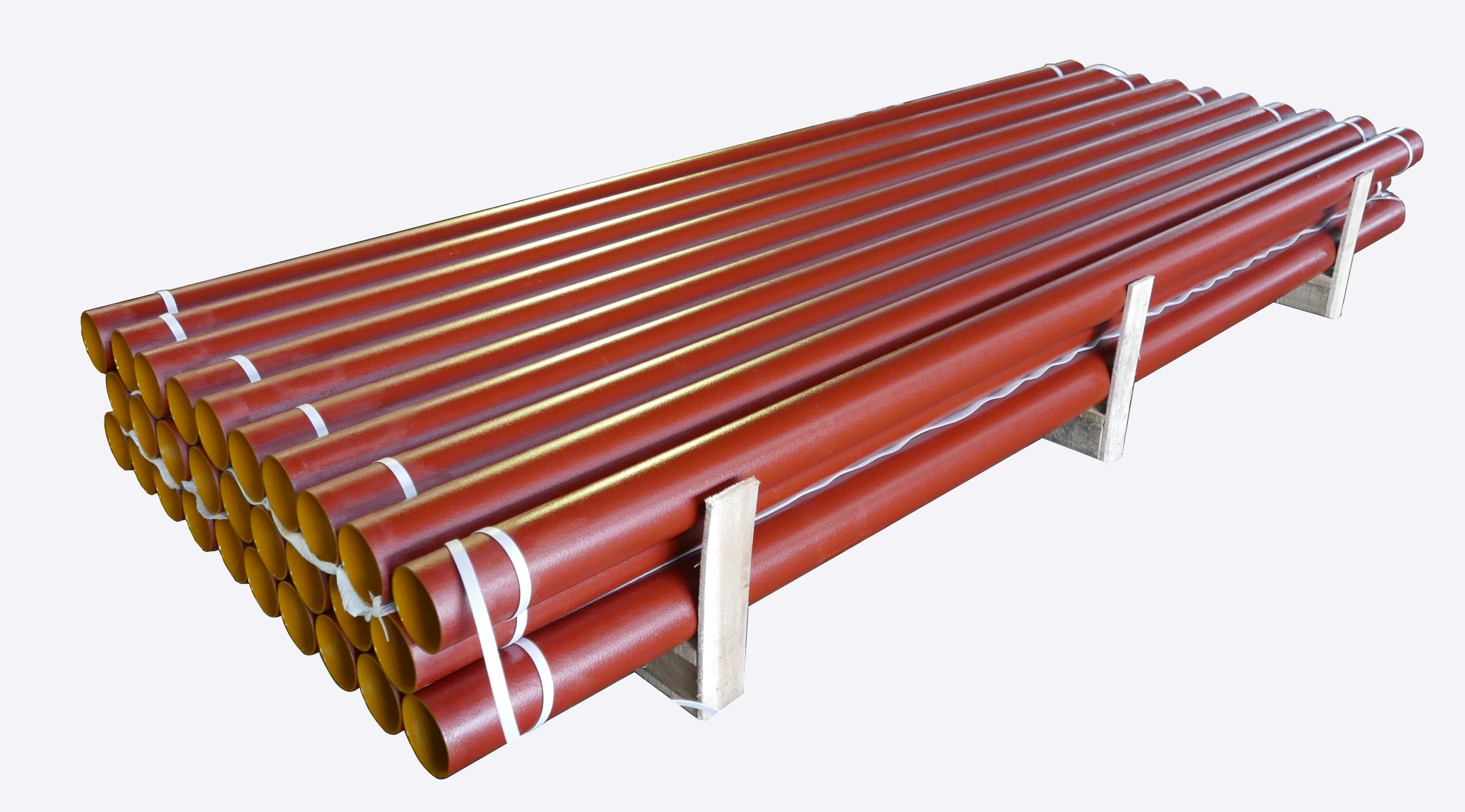

precision cast rion casting exporters

3. Design Flexibility The precision casting process allows for intricate designs that are difficult to achieve with other manufacturing methods. This means that industries requiring complex shapes and features can rely on precision cast iron products to meet their specifications.

4. Thermal Resistance Cast iron has excellent thermal conductivity and can withstand high temperatures, making it an ideal choice for applications such as exhaust manifolds and heat exchangers.

Challenges Faced by Exporters

Despite the numerous advantages, precision cast iron casting exporters face several challenges. Fluctuations in global demand, changes in trade regulations, and competitive pricing from local manufacturers can affect their operations. Additionally, maintaining quality standards across different regions can be challenging, as this industry requires strict adherence to specifications and safety standards.

Future Trends in the Industry

The future of precision cast iron casting is promising, particularly with advancements in technology. Companies are increasingly adopting automation and artificial intelligence to enhance production efficiency and quality control. Moreover, the growing emphasis on sustainability is pushing exporters to explore eco-friendly production methods, such as reducing waste and utilizing recycled materials.

Conclusion

Precision cast iron casting exporters play a crucial role in the global supply chain, providing high-quality components essential for various industries. As the demand for durable and precise parts continues to rise, these exporters must navigate challenges while embracing technological advancements to thrive in this competitive market. With their expertise and commitment to quality, precision cast iron casting exporters will remain instrumental in driving innovation and meeting the needs of manufacturers worldwide.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025