- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 09, 2024 07:36 Back to list

Mold Design for Punching Concrete Pipe Bottom Rings and Their Applications.

Understanding Punch Concrete Pipe Mold Bottom Ring

The concrete pipe industry has witnessed significant advancements in technology and methodology over the years, one of which is the development of specialized molds for the production of concrete pipes. Among these innovations, the punch concrete pipe mold bottom ring plays a critical role in ensuring the efficiency and quality of concrete pipe manufacturing. This article explores the functionality, importance, and application of the punch concrete pipe mold bottom ring in the industry.

What is a Punch Concrete Pipe Mold Bottom Ring?

The punch concrete pipe mold bottom ring is an integral component of the concrete pipe manufacturing process. It is essentially a detachable part that fits onto the bottom of the mold, where cement is poured to create cylindrical concrete pipes. The central feature of the bottom ring is its design, which includes specific geometrical shapes and openings that facilitate the molding process, ensuring that the concrete sets perfectly and retains the desired dimensions.

Importance of the Bottom Ring in Molding

One of the primary functions of the bottom ring is to provide support and stability during concrete pouring. When concrete is poured into the mold, it exerts pressure on the mold walls. The bottom ring helps distribute this pressure evenly, preventing deformation. Moreover, it ensures the mold maintains its shape throughout the setting process, which is critical for producing high-quality pipes.

Additionally, the design of the bottom ring is typically structured to allow for the incorporation of cores or inserts. This ensures that any necessary features, such as holes or recesses, can be molded directly into the pipe, greatly enhancing the functionality and versatility of the final product.

Manufacturing Process and Materials

The bottom ring is usually made from high-strength materials designed to withstand the harsh conditions of the concrete curing process. Common materials include steel and reinforced alloys, which provide durability and resistance to wear and tear. The manufacturing process involves precision engineering to ensure that every bottom ring meets strict specifications. CNC (Computer Numerical Control) machining is often employed, resulting in highly accurate and consistently shaped products.

Advantages of Using Punch Concrete Mold Bottom Rings

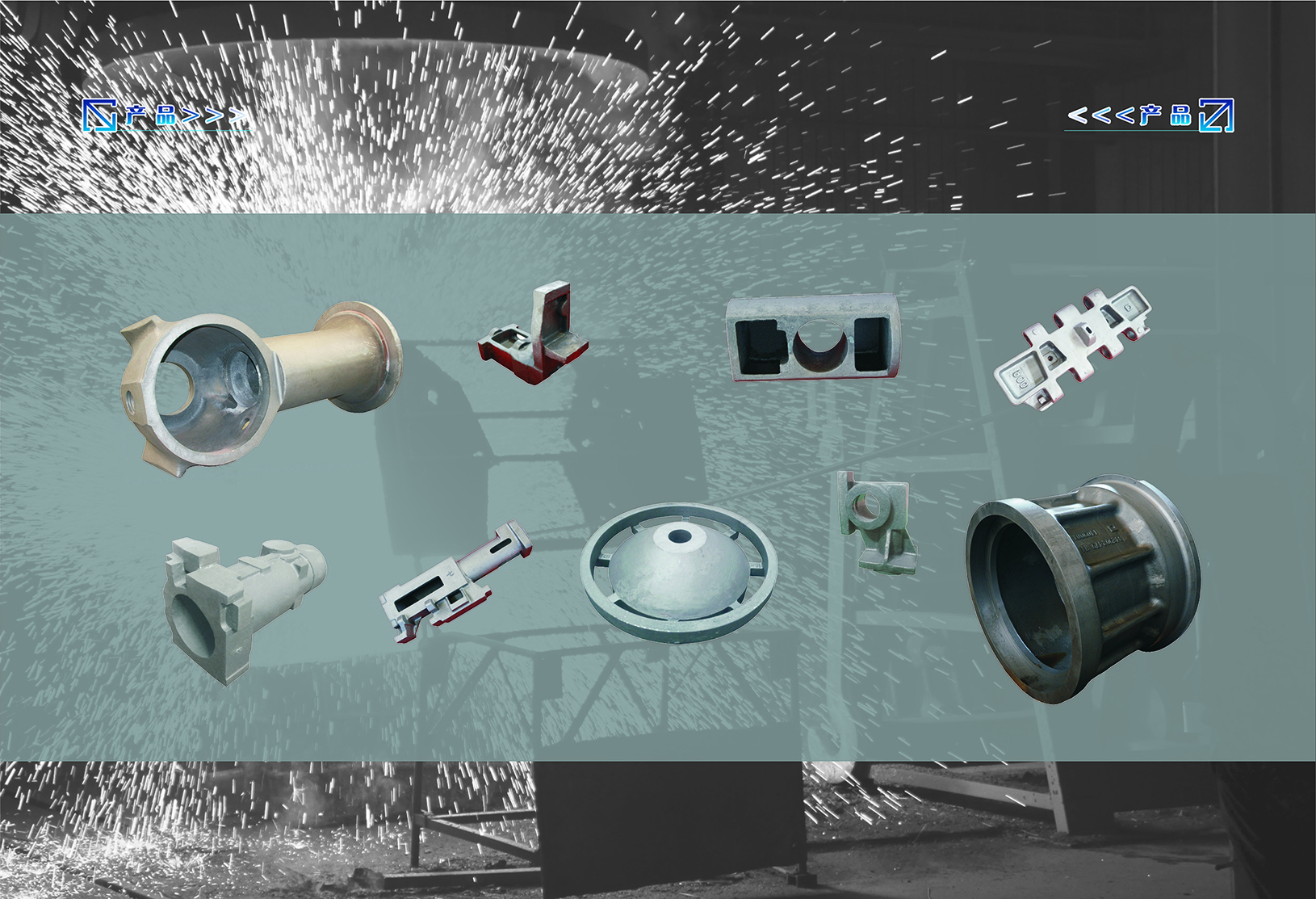

punch concrete pipe mold bottom ring

1. Quality Control The use of bottom rings enhances the quality of concrete pipes. With proper support and shape retention, the pipes produced are more likely to meet the required standards for density, strength, and dimension.

2. Efficiency The design of the bottom ring allows for more efficient pouring and setting. When molds are set up properly, manufacturers can operate at a faster pace without compromising product quality.

3. Customization Many manufacturers offer customizable bottom rings designed to meet specific requirements. This is particularly beneficial for producing specialized concrete pipes for unique applications, whether for construction, drainage, or municipal use.

4. Cost-Effectiveness Although the initial investment in high-quality molds and bottom rings may be higher, the long-term savings associated with reduced material wastage, minimized labor, and enhanced durability can significantly reduce overall production costs.

Application in the Concrete Pipe Industry

Punch concrete pipe mold bottom rings are employed in various sectors within the concrete industry. Whether for utility pipelines, culverts, or stormwater management systems, the bottom ring's role is essential. Its effectiveness in producing reliable and durable concrete structures means that it has become a standard component in modern concrete pipe manufacturing techniques.

As the construction industry continues to evolve, the implementation of advanced technologies and materials will likely lead to further enhancements in mold design. Manufacturers are continuously seeking ways to optimize their processes, and the punch concrete pipe mold bottom ring is a prime example of how innovative engineering can drive improvements in product quality and manufacturing efficiency.

Conclusion

In conclusion, the punch concrete pipe mold bottom ring serves a crucial function in the production of concrete pipes. Its ability to stabilize the mold, ensure quality, and enhance efficiency cannot be overstated. As technology progresses, the significance of these bottom rings will only grow, paving the way for more sophisticated concrete solutions in the infrastructure landscape. For concrete pipe manufacturers looking to improve product performance and manufacturing processes, investing in high-quality punch concrete pipe mold bottom rings is an essential step toward achieving excellence in their operations.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025