- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 21, 2024 10:52 Back to list

Punching Molds for Cement Concrete Pipe Pallets by Leading Manufacturer Solutions

The Importance of Quality in Punching Cement Concrete Pipe Mold Pallet Manufacturing

In the construction industry, the production of high-quality cement concrete pipes is crucial for various applications such as drainage systems, sewage treatment, irrigation, and infrastructure development. One of the key elements in the manufacturing process of these pipes is the use of molds and pallets. Punching cement concrete pipe molds and pallets form the backbone of the production process, determining both the efficiency of manufacturing and the quality of the final product. Therefore, selecting a reliable manufacturer for these materials is of paramount importance.

Understanding Punching Cement Concrete Pipe Molds

Punching molds are designed to create specific shapes and sizes of concrete pipes. The punching process involves forming the pipe's inner structure, allowing for the creation of holes necessary for various functionality—be it for drainage, ventilation, or simply to reduce the overall weight of the pipes. These molds must be made from durable materials that can withstand the pressures of the concrete pouring process and the subsequent curing stages.

High-quality punching molds are engineered to provide precise dimensions, ensuring tightly fitted pipes that meet engineering standards. Variations in mold quality can lead to non-uniform pipes, which can cause leaks and structural failures. Therefore, choosing a manufacturer that specializes in high-quality punching cement concrete pipe molds ensures that the pipes produced are both reliable and durable.

The Role of Pallets in Pipe Production

In addition to molds, pallets play a crucial role in the production of cement concrete pipes. Pallets are used to support the molds during the concrete pouring and curing stages. Quality pallets must be robust and designed to bear the heavy load of wet concrete. Furthermore, they need to be resistant to moisture and other environmental factors to ensure their longevity and effectiveness.

A well-manufactured pallet improves the efficiency of the production process by allowing for quicker and easier handling of the molds. This, in turn, contributes to reduced labor costs and improved productivity in the manufacturing facility. Manufacturers that focus on creating high-standard pallets can significantly enhance the overall workflow, benefiting the entire operation.

Choosing a Reliable Manufacturer

punching cement concrete pipe mold pallet manufacturer

When looking for a manufacturer of punching cement concrete pipe molds and pallets, several factors should be taken into consideration

1. Experience and Expertise Look for manufacturers with a proven track record in the industry. Companies that have been in business for several years often have the necessary experience to produce high-quality molds and pallets.

2. Material Quality The materials used in the production of molds and pallets should be durable and suitable for the planned applications. Manufacturers should be transparent about their material sourcing and production processes.

3. Customization Options Different projects may require specific mold designs and pallet sizes. A manufacturer that offers customization can provide solutions tailored to your specific needs.

4. Quality Assurance Ensure that the manufacturer adheres to quality control standards. Certifications and industry standards can be indicators of the quality of their products.

5. Customer Support Choose a manufacturer that provides excellent customer service, including support for installation and usage guidance.

6. Cost-Effectiveness While price should not be the sole determinant, it is essential to find a manufacturer that offers competitive pricing without compromising on quality.

In conclusion, the quality of punching cement concrete pipe molds and pallets is integral to the manufacturing of reliable cement concrete pipes. By partnering with a skilled manufacturer, construction companies can ensure the production of durable and efficient pipes, ultimately leading to safer and more sustainable infrastructure development. The choice of a manufacturer is not just a business decision; it is a commitment to quality and reliability in construction.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

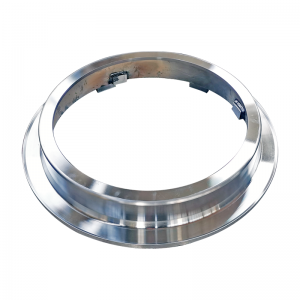

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025