- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 11, 2024 23:38 Back to list

Ductile Iron Casting Solutions for Railway Accessory Manufacturing and Design

The Importance of Ductile Iron Casting in Railway Accessory Production

Ductile iron, also known as spherical graphite iron, has become a material of choice for various applications in the railway industry, particularly in the production of railway accessories. This material exhibits unique properties that make it suitable for demanding environments and applications, ensuring the safety and efficiency of transportation systems. This article explores the significance of ductile iron casting in railway accessory manufacturing and its advantages over other materials.

The Role of Railway Accessories

Railway accessories play a crucial role in the safety and efficacy of the entire rail transport system. These components include rail fastening systems, wheel stops, couplings, and many other elements vital for ensuring smooth rail operations. Given the critical nature of these accessories, they must possess exceptional mechanical properties, durability, and resistance to wear and tear. This is where ductile iron casting shines, providing superior performance compared to traditional grey iron or steel.

Exceptional Mechanical Properties

One of the primary reasons for the adoption of ductile iron in railway applications lies in its outstanding mechanical properties. Ductile iron boasts a tensile strength that can surpass steel while maintaining high levels of ductility and toughness. This combination of strength and flexibility is crucial for railway accessories, which are subject to high-impact loads and dynamic stresses during operation. The material's ability to absorb shocks helps prevent failures that could disrupt service or compromise safety.

Corrosion Resistance and Longevity

Moreover, ductile iron possesses good corrosion resistance, particularly when treated with appropriate coatings. Railway accessories are often exposed to harsh environmental conditions, including moisture and chemicals, which can lead to rapid deterioration of materials. Ductile iron's resistance to these elements translates into longer service life and reduced maintenance costs. By utilizing this material, manufacturers can produce components that perform reliably over extended periods, minimizing the frequency of replacements and repairs.

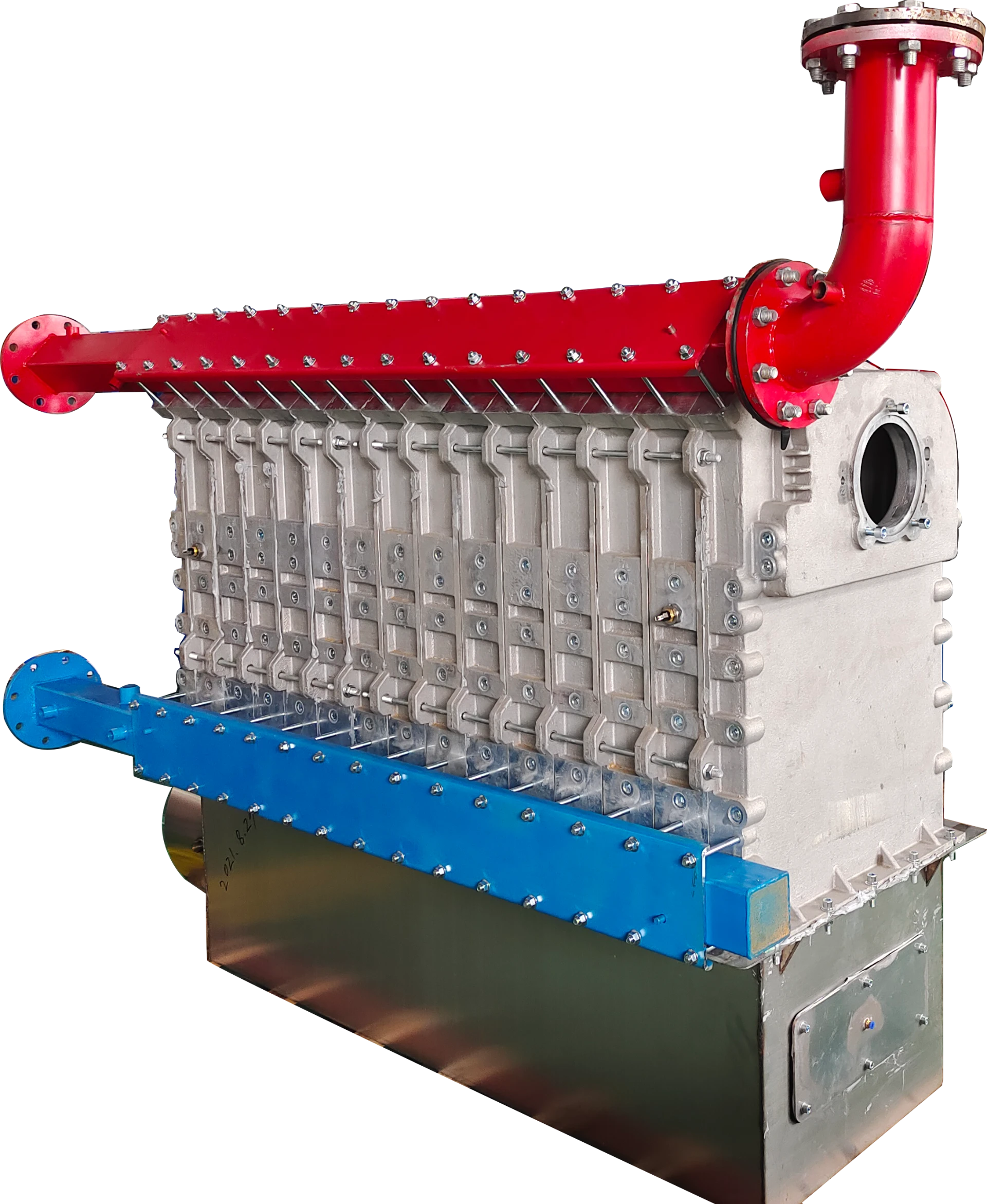

railway accessory ductile iron casting

Cost-Effectiveness

While the initial costs of ductile iron casting might seem higher compared to other materials, the overall lifecycle cost benefits are significant. The durability and longevity of ductile iron components lead to lower maintenance and replacement costs over time, making them a more cost-effective solution in the long run. Rail operators can benefit from investing in high-quality ductile iron accessories that reduce downtime and improve operational efficiency.

Design Flexibility

Another advantage of ductile iron casting is the flexibility it offers in design and manufacturing. Ductile iron can be cast into intricate shapes and sizes, allowing for the production of complex components that meet specific engineering requirements. This flexibility enables designers to create innovative solutions that enhance the functionality and performance of railway systems. The casting process itself also allows for high production volumes, making it easier to meet the growing demands of the railway industry.

Sustainability Considerations

Sustainability is becoming increasingly important in the manufacturing sector, and the railway industry is no exception. Ductile iron is often produced using recycled materials, which reduces the environmental impact associated with mining and new material production. Additionally, the extended lifespan of ductile iron components contributes to sustainability by reducing waste and resource consumption over time.

Conclusion

In conclusion, ductile iron casting plays an essential role in the production of railway accessories, delivering outstanding mechanical properties, corrosion resistance, and cost-effectiveness. As the railway industry continues to evolve, the demand for high-quality, durable, and efficient components will only grow. Ductile iron offers the perfect solution to meet these needs, providing a reliable foundation for the future of railway transportation. By recognizing and leveraging the benefits of ductile iron casting, manufacturers can play a significant role in enhancing the safety, efficiency, and sustainability of railway systems worldwide.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025