- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 17, 2024 12:27 Back to list

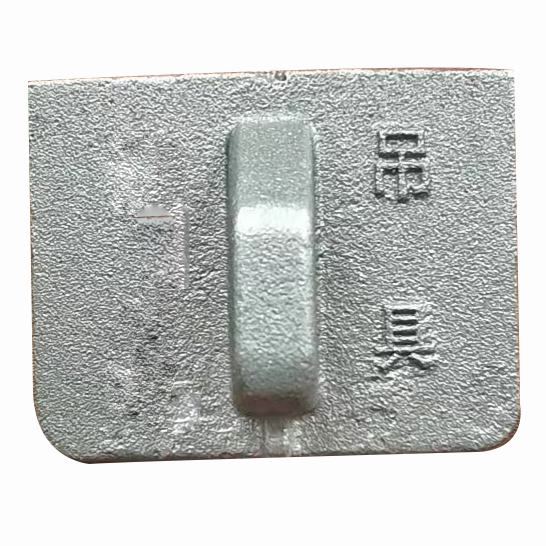

Room heating factories utilize heat exchangers for efficient temperature control.

The Vital Role of Heat Exchangers in Room Heating for Industrial Facilities

In the realm of industrial heating systems, heat exchangers play an indispensable role, particularly in room heating factories. These innovative devices serve as the backbone of efficient energy transfer, ensuring optimal warmth and comfort in workspaces while maximizing energy efficiency.

A heat exchanger is a mechanical device designed to transfer thermal energy from one medium to another, facilitating the process of heating or cooling. In the context of room heating factories, they are employed to extract waste heat from manufacturing processes and redistribute it to warm the surrounding environment. This not only conserves energy but also reduces operational costs, making it a sustainable and economically viable solution.

The primary function of a heat exchanger in room heating factories is to recover heat that would otherwise be lost during production. For instance, in industries like steel manufacturing or chemical processing, substantial amounts of heat are generated, which can be harnessed through heat exchangers. By capturing this heat, they prevent energy wastage and contribute significantly to the overall energy efficiency of the facility.

Heat exchangers come in various types, including shell and tube, plate, and finned tube designs, each tailored to suit specific industrial requirements. The choice of heat exchanger depends on factors such as the temperature and pressure of the fluids involved, the required heat transfer rate, and available space.

The integration of heat exchangers in room heating factories also promotes a safer working environment

The integration of heat exchangers in room heating factories also promotes a safer working environment The integration of heat exchangers in room heating factories also promotes a safer working environment

The integration of heat exchangers in room heating factories also promotes a safer working environment

The integration of heat exchangers in room heating factories also promotes a safer working environment

The integration of heat exchangers in room heating factories also promotes a safer working environment heat exchanger for room heating factories. By maintaining consistent room temperatures, they help prevent temperature-related accidents and improve worker comfort, leading to increased productivity. Furthermore, they contribute to the overall sustainability profile of the factory by reducing greenhouse gas emissions associated with energy consumption.

Innovations in heat exchanger technology continue to push the boundaries of efficiency. Advanced materials, improved designs, and smart control systems allow for more precise temperature regulation and higher heat transfer rates. As we move towards a greener future, the importance of heat exchangers in room heating factories will only grow, fostering a balance between industrial operations and environmental responsibility.

In conclusion, heat exchangers form a crucial element in the efficient heating of room environments within factories. They not only ensure a comfortable and safe workspace but also contribute significantly to energy conservation and the reduction of carbon footprint. As technology advances, the role of heat exchangers in industrial heating systems is set to become even more pivotal in the quest for sustainable and eco-friendly manufacturing practices.

heat exchanger for room heating factories. By maintaining consistent room temperatures, they help prevent temperature-related accidents and improve worker comfort, leading to increased productivity. Furthermore, they contribute to the overall sustainability profile of the factory by reducing greenhouse gas emissions associated with energy consumption.

Innovations in heat exchanger technology continue to push the boundaries of efficiency. Advanced materials, improved designs, and smart control systems allow for more precise temperature regulation and higher heat transfer rates. As we move towards a greener future, the importance of heat exchangers in room heating factories will only grow, fostering a balance between industrial operations and environmental responsibility.

In conclusion, heat exchangers form a crucial element in the efficient heating of room environments within factories. They not only ensure a comfortable and safe workspace but also contribute significantly to energy conservation and the reduction of carbon footprint. As technology advances, the role of heat exchangers in industrial heating systems is set to become even more pivotal in the quest for sustainable and eco-friendly manufacturing practices.

The integration of heat exchangers in room heating factories also promotes a safer working environment

The integration of heat exchangers in room heating factories also promotes a safer working environment

The integration of heat exchangers in room heating factories also promotes a safer working environment

The integration of heat exchangers in room heating factories also promotes a safer working environment heat exchanger for room heating factories. By maintaining consistent room temperatures, they help prevent temperature-related accidents and improve worker comfort, leading to increased productivity. Furthermore, they contribute to the overall sustainability profile of the factory by reducing greenhouse gas emissions associated with energy consumption.

Innovations in heat exchanger technology continue to push the boundaries of efficiency. Advanced materials, improved designs, and smart control systems allow for more precise temperature regulation and higher heat transfer rates. As we move towards a greener future, the importance of heat exchangers in room heating factories will only grow, fostering a balance between industrial operations and environmental responsibility.

In conclusion, heat exchangers form a crucial element in the efficient heating of room environments within factories. They not only ensure a comfortable and safe workspace but also contribute significantly to energy conservation and the reduction of carbon footprint. As technology advances, the role of heat exchangers in industrial heating systems is set to become even more pivotal in the quest for sustainable and eco-friendly manufacturing practices.

heat exchanger for room heating factories. By maintaining consistent room temperatures, they help prevent temperature-related accidents and improve worker comfort, leading to increased productivity. Furthermore, they contribute to the overall sustainability profile of the factory by reducing greenhouse gas emissions associated with energy consumption.

Innovations in heat exchanger technology continue to push the boundaries of efficiency. Advanced materials, improved designs, and smart control systems allow for more precise temperature regulation and higher heat transfer rates. As we move towards a greener future, the importance of heat exchangers in room heating factories will only grow, fostering a balance between industrial operations and environmental responsibility.

In conclusion, heat exchangers form a crucial element in the efficient heating of room environments within factories. They not only ensure a comfortable and safe workspace but also contribute significantly to energy conservation and the reduction of carbon footprint. As technology advances, the role of heat exchangers in industrial heating systems is set to become even more pivotal in the quest for sustainable and eco-friendly manufacturing practices. Share

Pervious:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025