- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 22, 2024 02:44 Back to list

sand cast exporters

Exploring the World of Sand Cast Exporters

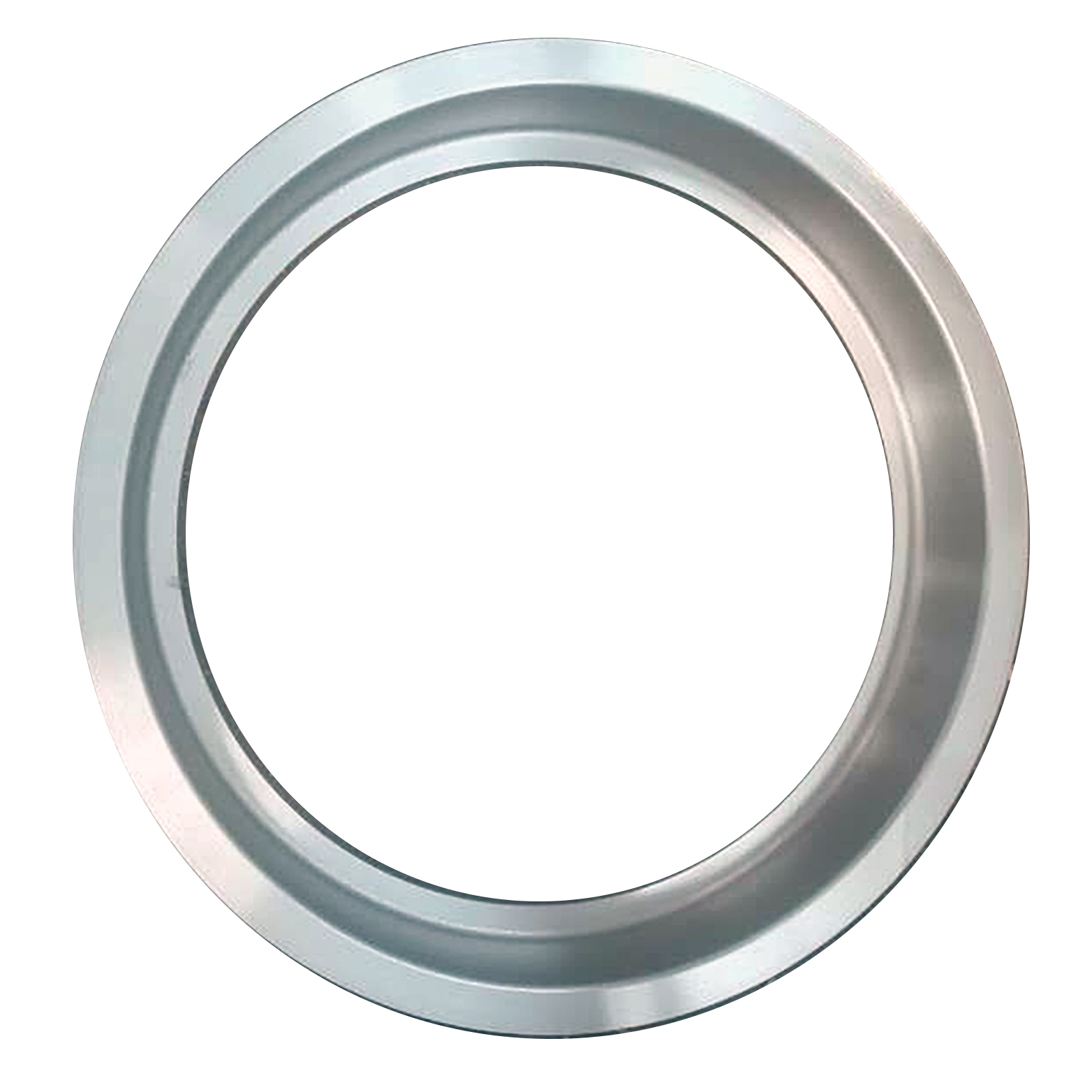

In the realm of manufacturing and engineering, sand casting is a widely used method that provides a cost-effective way to create complex metal parts. The process involves pouring molten metal into a sand mold, which hardens to form the desired shape. As global demand for customized metal components continues to rise, sand cast exporters play a crucial role in the supply chain, facilitating trade in this essential industry.

Sand cast exporters are enterprises that specialize in providing sand-cast components to various sectors, including automotive, aerospace, construction, and equipment manufacturing. They cater to clients who require high-quality, durable products designed to meet specific engineering specifications. The appeal of sand casting lies in its versatility; it can accommodate a range of metals—such as aluminum, iron, and bronze—and can produce parts of various sizes and complexities.

One of the primary advantages of working with sand cast exporters is their ability to leverage local resources and labor. Many exporters operate in regions rich in sand and metal resources, allowing them to minimize production costs and offer competitive prices. Furthermore, the expertise found in these local industries can lead to innovative solutions, enhancing the quality and performance of the final products.

sand cast exporters

As environmental concerns become increasingly important, many sand cast exporters are adopting more sustainable practices

. This includes the use of recycled materials and modern technologies that reduce waste and energy consumption during the casting process. By embracing these initiatives, exporters not only meet the demands of eco-conscious consumers but also position themselves as responsible players in the global market.In addition to their manufacturing capabilities, sand cast exporters often provide a range of services, including design assistance, prototyping, and quality assurance. Their involvement in the early stages of product development can significantly impact the final outcome, ensuring that the products meet industry standards and customer expectations.

The rise of digital technology has also transformed the landscape for sand cast exporters. Advanced software for simulation and modeling allows for more precise designs and reduced lead times. Moreover, digital communication tools have made it easier for exporters to connect with international clients, expanding their reach and fostering global collaboration.

In conclusion, sand cast exporters are vital contributors to the manufacturing industry, providing high-quality, customized metal components that meet the diverse needs of various sectors. Through sustainable practices, advanced technology, and a commitment to customer service, these exporters continue to thrive in a competitive global market, paving the way for innovative solutions in metal production.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025