- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 29, 2024 21:57 Back to list

Exploring the Applications and Benefits of Sand Casting in Manufacturing Industry

Understanding Sand Casting Parts A Comprehensive Overview

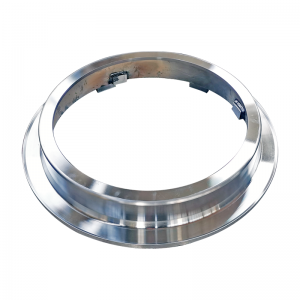

Sand casting, also known as sand mold casting, is one of the oldest and most widely used manufacturing processes in the metalworking industry. This technique involves creating a mold from sand and pouring molten metal into the cavity formed within that mold. The versatility and cost-effectiveness of sand casting make it a preferred method for producing a variety of metal parts across multiple industries, including automotive, aerospace, and marine.

The Sand Casting Process

The sand casting process begins with the creation of a pattern, which is a replica of the final part to be produced. This pattern can be made from various materials such as wood, metal, or plastic and is designed to be slightly larger than the final product to account for shrinkage during cooling. Once the pattern is ready, it is placed in a mold made of sand mixed with a binder to help maintain its shape.

The mold is created by packing sand around the pattern, usually in two halves, known as the cope and drag. After the sand has set, the two halves of the mold are separated, the pattern is removed, and any necessary cores are inserted to create internal cavities in the final part. The two halves of the mold are then reassembled, and molten metal is poured into the cavity through a sprue.

Advantages of Sand Casting

One of the most significant advantages of sand casting is its ability to produce complex shapes with high precision. The process can accommodate a wide range of metals—ferrous and non-ferrous alike, such as aluminum, iron, bronze, and brass—making it highly versatile. Moreover, sand casting operates well for both small and large production runs. It can be economically viable for low-volume production, while also scaling up for larger quantities in an efficient manner.

Another notable benefit is the relatively low cost of materials. Sand is abundant and inexpensive, making it an appealing choice for manufacturers. Additionally, the sand can be reused multiple times with proper reclamation processes, contributing to lower environmental impact and waste management costs.

sand casting parts

Applications of Sand Casting Parts

The application of sand casting is vast. It is particularly beneficial in industries where complex geometries and intricate designs are prevalent. In the automotive industry, sand castings are used for engine blocks, cylinder heads, and various brackets. In aerospace, parts like turbine housings and brackets benefit from the lightweight and high-strength characteristics of cast metals.

Furthermore, sand casting is also employed in artistic and architectural applications. Sculptures, decorative elements, and structural components can be crafted using this method, allowing for creative freedom and unique designs.

Challenges in Sand Casting

Despite its many advantages, sand casting does present some challenges. Surface finish quality is often lower compared to other casting processes such as investment casting, which may require additional machining to achieve the desired characteristics. Furthermore, defects such as sand inclusion, porosity, and shrinkage can occur if not properly managed.

To mitigate these challenges, manufacturers invest in rigorous quality control and testing processes. Employing modern technologies, such as 3D printing for patterns or advanced simulation software, can also enhance the precision and efficiency of sand casting.

Conclusion

Sand casting remains a fundamental manufacturing process that plays a crucial role in producing metal parts. Its adaptability to various materials, combined with its capability to create complex shapes, makes it an invaluable method in different sectors. While challenges exist, continuous advancements in technology and quality control methods are helping to enhance the overall effectiveness and reliability of sand casting. Whether for industrial applications or artistic endeavors, the impact of sand casting parts is significant and far-reaching, securing its place in the future of manufacturing.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025