- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 29, 2024 19:55 Back to list

shell and tube heat exchanger for sale

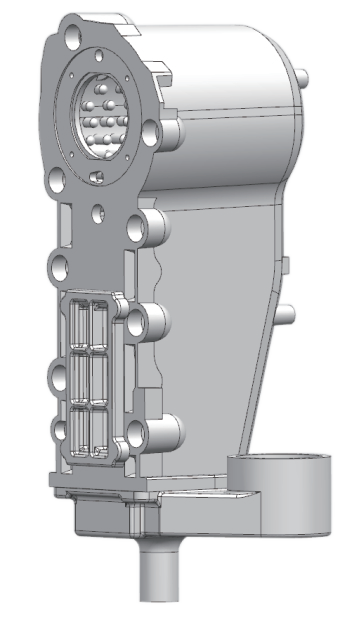

Shell and Tube Heat Exchangers for Sale An Overview

In various industrial processes, the efficient transfer of heat is paramount for optimal operation and energy conservation. One of the most widely used designs in this sector is the shell and tube heat exchanger. These heat exchangers are renowned for their reliability and versatility, making them a popular choice in several applications ranging from chemical processing to power generation.

A shell and tube heat exchanger consists of a series of tubes, one set carrying the hot fluid and another carrying the cold fluid. The design enables an efficient heat exchange between the two fluids as they flow in separate channels while allowing for high-pressure applications. This construction gives shell and tube heat exchangers an advantage over other types of exchangers due to their ability to handle high temperatures and pressures, thus making them suitable for heavy industrial uses.

When looking for shell and tube heat exchangers for sale, potential buyers must consider several factors. First and foremost, it’s essential to evaluate the materials of construction. Common materials include stainless steel, carbon steel, and alloys that are resistant to corrosion and are suitable for the specific applications intended. Depending on the fluids involved and the working conditions, selecting the right material is crucial to ensure durability and efficiency.

shell and tube heat exchanger for sale

Another critical factor is the heat transfer surface area. The design can vary significantly, with options available to optimize performance based on flow rates and thermal requirements. Buyers should assess the heat exchanger specifications to ensure they meet the demands of their particular system. A larger surface area usually translates to better heat transfer efficiency, but it may also occupy more space and require more maintenance.

In addition, maintenance and cleaning should not be overlooked. Shell and tube heat exchangers are relatively easy to clean due to their design, but regular inspections and maintenance can prevent fouling and scaling, which can degrade performance over time. Buyers should inquire about maintenance services or guidelines from the supplier.

Moreover, it’s essential to choose a reputable manufacturer or supplier. Investigating customer reviews and seeking recommendations can lead to high-quality options. A reliable vendor will offer warranties and support to ensure that the heat exchanger installed performs optimally throughout its service life.

In conclusion, shell and tube heat exchangers are crucial components in many industrial applications, and finding the right one for sale requires thorough research and consideration of material, design, efficiency, and supplier reputation. By choosing wisely, industries can enhance productivity, reduce energy consumption, and ensure the longevity of their heat transfer systems.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025