- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 27, 2024 20:32 Back to list

Shell Molding Casting Suppliers for High-Quality Precision Metal Parts Manufacturing

Understanding Shell Molding Casting A Comprehensive Guide for Manufacturers

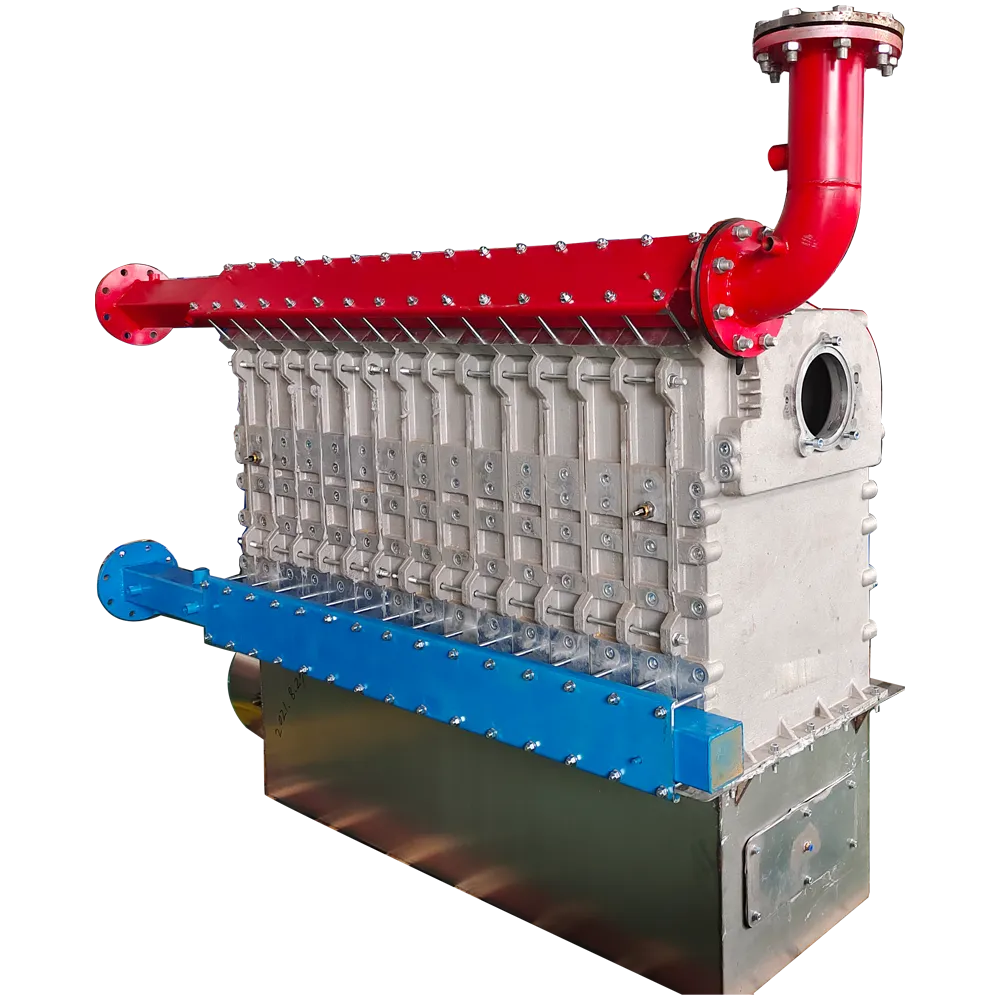

Shell molding casting is a sophisticated and efficient manufacturing process used primarily in the production of metal components. Derived from the traditional sand casting methods, shell molding offers enhanced precision and surface finish, making it a preferred choice in various industries, including automotive, aerospace, and machinery. This article delves into the intricacies of shell molding casting, its advantages, common applications, and a look at some of the leading manufacturers in the field.

What is Shell Molding Casting?

Shell molding casting involves creating a mold by heating a mixture of fine sand and thermosetting resin. The mold is formed around a pattern, which is usually made of metal, allowing for excellent heat transfer. The process begins when the sand-resin mixture is heated and then applied to the pattern, creating a shell. After sufficient cooling, the shell is removed from the pattern, and the two halves of the mold are assembled to create a cavity for metal pouring. Once the molten metal is introduced and solidifies, the mold can be broken apart for extraction.

Advantages of Shell Molding Casting

1. Superior Surface Finish One of the most significant advantages of shell molding casting is its ability to produce components with excellent surface finish. The smoothness of the shell allows for minimal post-processing, reducing time and cost.

2. Dimensional Accuracy The precision of the molding process results in parts that require minimal machining, which is crucial in industries where tolerances are vital.

3. High Production Rates Shell molding is suitable for high-volume production runs, making it a cost-effective choice for manufacturers.

4. Versatility This method can accommodate various metals, including iron, steel, and non-ferrous alloys, making it widely applicable across different sectors.

shell molding casting manufacturers

Common Applications

Shell molding casting is widely used in several industries due to its numerous advantages. Some common applications include

- Automotive Industry Components such as engine blocks, transmission cases, and various other parts that require strength and precision. - Aerospace Components Parts that demand lightweight solutions without compromising strength, such as brackets, housings, and turbine components.

- Industrial Machinery Many industrial machines require durable and heavy components that shell molding can efficiently produce.

- Defense and Military Equipment High-performance and safety-critical parts are often manufactured using this method to ensure longevity and reliability.

Leading Manufacturers

Several manufacturers are recognized in the shell molding casting industry for their expertise and innovative practices. Companies such as Morris Group International, Apex Technologies, and Baker Hughes are known for their cutting-edge facilities and commitment to quality. Their investment in technology and skilled workforce enables them to produce complex, high-precision parts that meet stringent industry standards.

Additionally, emerging firms focusing on sustainability practices in manufacturing are gaining traction. By adopting eco-friendly materials and processes, these companies align with global trends towards greener production methods, appealing to a broader market base.

Conclusion

Shell molding casting presents a strategic manufacturing solution for producing high-quality components across various industries. Its benefits, including superior surface finish, dimensional accuracy, and versatility, position it as a preferred choice for many manufacturers. As the industry continues to evolve, staying informed about advancements and best practices in shell molding casting will be essential for those involved in production and design. Whether you are a manufacturer or a buyer, understanding this process can empower you to make informed decisions that enhance your operational capabilities and competitiveness in the market.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025