- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 06, 2024 23:42 Back to list

src concrete pipe mould pallet factories

The Importance of SRC Concrete Pipe Mould Pallet Factories

In the rapidly evolving construction industry, the demand for high-quality concrete products is constantly on the rise. Among these essential products are concrete pipes, which are crucial for sewage, drainage, and various utility applications. To meet this demand, SRC (Steel Reinforced Concrete) pipe mould pallet factories play a vital role in producing efficient and durable concrete solutions.

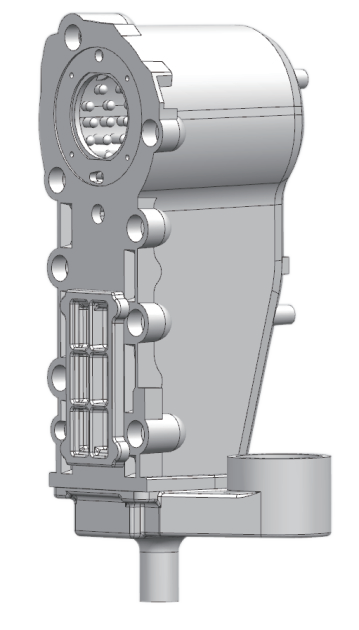

SRC concrete pipes are renowned for their strength and longevity. They are manufactured using a specialized process that reinforces concrete with steel, thereby enhancing its structural integrity. The moulds used in producing these pipes are of paramount importance as they dictate the shape, size, and quality of the final product. This is where mould pallet factories come into play.

Mould pallet factories utilize advanced technology and high-precision machinery to create moulds that are essential for the production of SRC concrete pipes. The process begins with the design and engineering of the moulds, which requires a deep understanding of both mechanical design and the properties of concrete. Engineers create detailed plans that ensure the moulds will produce pipes that meet industry standards for strength and durability.

Once the designs are finalized, the manufacturing of moulds takes place. Factories typically use durable materials such as steel and reinforced plastics to construct moulds that can withstand the rigors of concrete production. Each mould is carefully crafted to ensure that it can handle the weight of the concrete and the pressure exerted during the curing process.

src concrete pipe mould pallet factories

In addition to manufacturing moulds, these factories often take on the role of producing the concrete pipes themselves. By using automated systems for pouring and curing the concrete within the moulds, they can achieve high levels of efficiency and consistency in their products. This automation not only speeds up production times but also minimizes human error, ensuring that each pipe produced is of the highest quality.

Environmental considerations also play a role in modern SRC concrete pipe mould pallet factories. Many of these facilities are implementing sustainable practices by recycling materials and reducing waste. For instance, using recycled aggregates in the concrete mix not only lowers costs but also lessens the environmental impact of the production process.

Finally, the importance of quality control cannot be understated in SRC concrete pipe mould production. Factories implement rigorous testing protocols to ensure that each batch of moulds and pipes meets strict safety and performance standards. This is crucial for maintaining the integrity of infrastructure projects, where failure is not an option.

In conclusion, SRC concrete pipe mould pallet factories are integral to the construction industry, providing the necessary moulds and pipes that ensure the efficient and sustainable management of water and waste. As technology advances and the demand for high-quality concrete products grows, these factories will continue to be a cornerstone of modern construction practices.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025