- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 22, 2024 07:03 Back to list

src concrete pipe pallet factory

The Importance of Concrete Pipe Pallet Factories in Infrastructure Development

Concrete pipes are integral components in modern infrastructure, playing a crucial role in sewage systems, drainage, and water supply networks. To ensure the proper production and transportation of these essential materials, concrete pipe pallet factories have emerged as key players in the industry. This article delves into the significance of these factories, their operational processes, and their overall impact on urban and rural development.

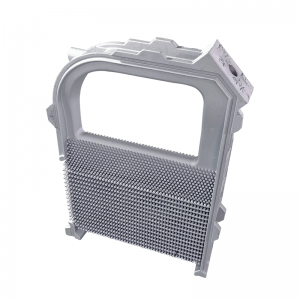

Concrete pipe pallet factories specialize in the manufacturing of concrete pipes and their associated pallets. The pallets serve as support structures that allow for the efficient handling and storage of pipes during transportation. The importance of these factories cannot be overstated, as they provide the foundational elements required for essential infrastructure projects that improve public health and enhance economic development.

The Importance of Concrete Pipe Pallet Factories in Infrastructure Development

Once the pipes are cast, they undergo a curing process. This stage is critical, as it allows the concrete to harden and attain its full strength. In many factories, modern curing techniques using steam or controlled environments are employed to expedite this process and enhance the overall quality of the pipes. After curing, the pipes are removed from their molds and placed onto the pallets. These pallets, often made from wood or plastic, provide a stable base that facilitates easy stacking and transportation.

src concrete pipe pallet factory

The design and production of pallets are also essential in the context of logistics. Factories often invest in durable, lightweight materials that not only support the weight of the concrete pipes but also minimize transportation costs. Efficient pallet design reduces the risk of damage during transit, ensuring that the pipes arrive at construction sites in optimal condition.

Concrete pipe pallet factories also contribute significantly to sustainability efforts within the construction industry. Many manufacturers are adopting eco-friendly practices by utilizing recycled materials and implementing energy-efficient production processes. Additionally, concrete pipes offer longevity and low maintenance requirements compared to alternative materials, thereby reducing the environmental impact over their lifecycle.

Furthermore, the proliferation of concrete pipe pallet factories can boost local economies. These factories create jobs ranging from production line workers to management and logistics personnel. By sourcing materials locally and distributing finished products to nearby construction projects, they also contribute to the regional economy. The presence of such factories in a community can lead to improved infrastructure, enhancing the quality of life for residents through better drainage systems, reliable water supply, and efficient waste management.

In conclusion, concrete pipe pallet factories play a pivotal role in the manufacturing and distribution of essential infrastructure components. Through advanced production techniques and sustainable practices, these factories not only meet the growing demand for concrete pipes but also contribute to economic and environmental sustainability. As urbanization continues to expand, the significance of these factories will only increase, as they enable the development of resilient and efficient infrastructure systems essential for modern society.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025