- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 23, 2024 02:56 Back to list

stamp concrete pipe mold bottom ring manufacturer

Stamp Concrete Pipe Mold Bottom Ring Manufacturer A Comprehensive Guide

In the realm of construction and infrastructure development, the role of concrete pipes cannot be overstated. These sturdy and durable structures are essential for the transportation of water, sewage, and other fluids in both urban and rural settings. One critical component in the production of concrete pipes is the mold bottom ring. This specialized part plays a crucial role in ensuring the quality and integrity of the final product.

A stamp concrete pipe mold bottom ring manufacturer is a company that specializes in the design, manufacturing, and supply of these essential components. These manufacturers work closely with engineers, contractors, and other stakeholders to understand the specific requirements of each project and provide customized solutions.

The process of manufacturing a concrete pipe mold bottom ring involves several critical steps. First, the manufacturer selects high-quality materials that are resistant to corrosion and wear. These materials include stainless steel, aluminum, or other alloys that can withstand the harsh conditions encountered during the casting process.

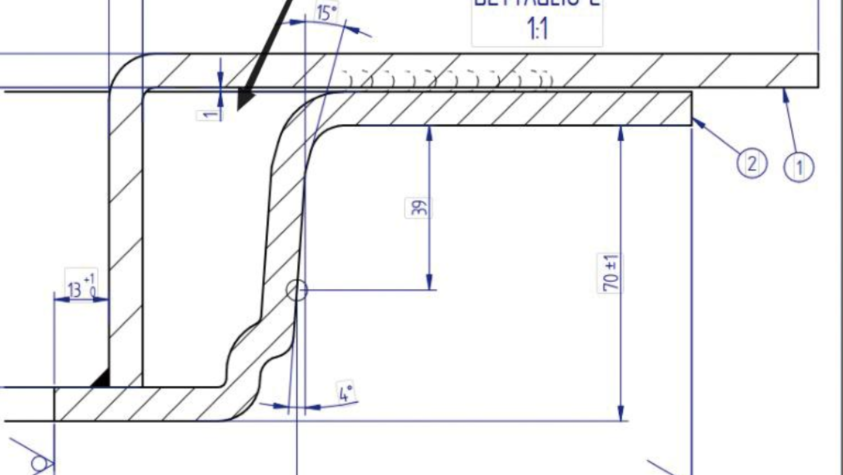

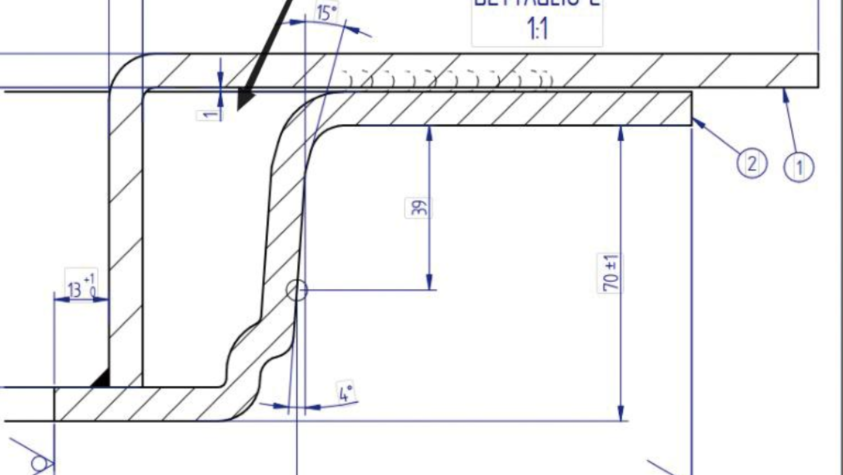

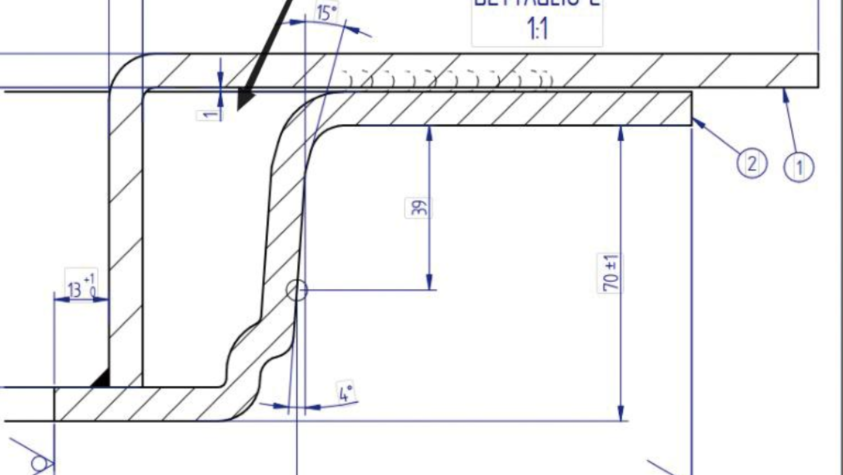

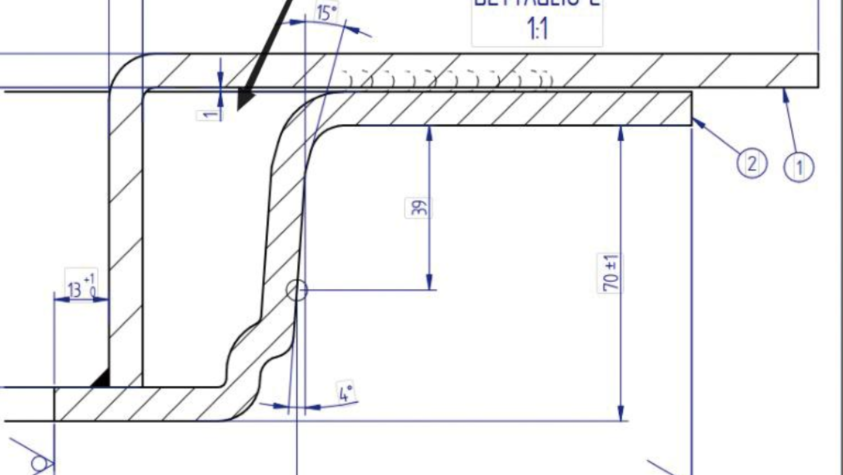

Once the materials have been selected, the manufacturer proceeds to create a detailed design of the mold bottom ring. This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances

This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances stamp concrete pipe mold bottom ring manufacturer. The design is then reviewed and approved by engineers and other experts before proceeding to the manufacturing stage.

The manufacturing process typically involves the use of advanced machinery and equipment. The mold bottom ring is precision-machined to ensure that it fits perfectly into the concrete pipe mold. The surface of the mold bottom ring is also treated to ensure that it is smooth and free from any defects that could affect the quality of the concrete pipe.

After the mold bottom ring has been manufactured, it is carefully inspected to ensure that it meets the required standards. Any defects or deviations from the design specifications are identified and corrected before the mold bottom ring is shipped to the customer.

Overall, the role of a stamp concrete pipe mold bottom ring manufacturer is crucial in ensuring the success of any concrete pipe project. By providing high-quality, customized solutions, these manufacturers help to streamline the production process, reduce costs, and improve the overall quality of the final product. As such, they play a vital role in the ongoing development of infrastructure and the built environment.

stamp concrete pipe mold bottom ring manufacturer. The design is then reviewed and approved by engineers and other experts before proceeding to the manufacturing stage.

The manufacturing process typically involves the use of advanced machinery and equipment. The mold bottom ring is precision-machined to ensure that it fits perfectly into the concrete pipe mold. The surface of the mold bottom ring is also treated to ensure that it is smooth and free from any defects that could affect the quality of the concrete pipe.

After the mold bottom ring has been manufactured, it is carefully inspected to ensure that it meets the required standards. Any defects or deviations from the design specifications are identified and corrected before the mold bottom ring is shipped to the customer.

Overall, the role of a stamp concrete pipe mold bottom ring manufacturer is crucial in ensuring the success of any concrete pipe project. By providing high-quality, customized solutions, these manufacturers help to streamline the production process, reduce costs, and improve the overall quality of the final product. As such, they play a vital role in the ongoing development of infrastructure and the built environment.

This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances

This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances This design takes into account factors such as the size and shape of the concrete pipe, the material properties of the concrete, and the required tolerances stamp concrete pipe mold bottom ring manufacturer. The design is then reviewed and approved by engineers and other experts before proceeding to the manufacturing stage.

The manufacturing process typically involves the use of advanced machinery and equipment. The mold bottom ring is precision-machined to ensure that it fits perfectly into the concrete pipe mold. The surface of the mold bottom ring is also treated to ensure that it is smooth and free from any defects that could affect the quality of the concrete pipe.

After the mold bottom ring has been manufactured, it is carefully inspected to ensure that it meets the required standards. Any defects or deviations from the design specifications are identified and corrected before the mold bottom ring is shipped to the customer.

Overall, the role of a stamp concrete pipe mold bottom ring manufacturer is crucial in ensuring the success of any concrete pipe project. By providing high-quality, customized solutions, these manufacturers help to streamline the production process, reduce costs, and improve the overall quality of the final product. As such, they play a vital role in the ongoing development of infrastructure and the built environment.

stamp concrete pipe mold bottom ring manufacturer. The design is then reviewed and approved by engineers and other experts before proceeding to the manufacturing stage.

The manufacturing process typically involves the use of advanced machinery and equipment. The mold bottom ring is precision-machined to ensure that it fits perfectly into the concrete pipe mold. The surface of the mold bottom ring is also treated to ensure that it is smooth and free from any defects that could affect the quality of the concrete pipe.

After the mold bottom ring has been manufactured, it is carefully inspected to ensure that it meets the required standards. Any defects or deviations from the design specifications are identified and corrected before the mold bottom ring is shipped to the customer.

Overall, the role of a stamp concrete pipe mold bottom ring manufacturer is crucial in ensuring the success of any concrete pipe project. By providing high-quality, customized solutions, these manufacturers help to streamline the production process, reduce costs, and improve the overall quality of the final product. As such, they play a vital role in the ongoing development of infrastructure and the built environment. Share

Latest news

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025