- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 16, 2024 17:13 Back to list

stamping concrete pipe mould pallet factories

The Importance of Stamping Concrete Pipe Mould Pallet Factories

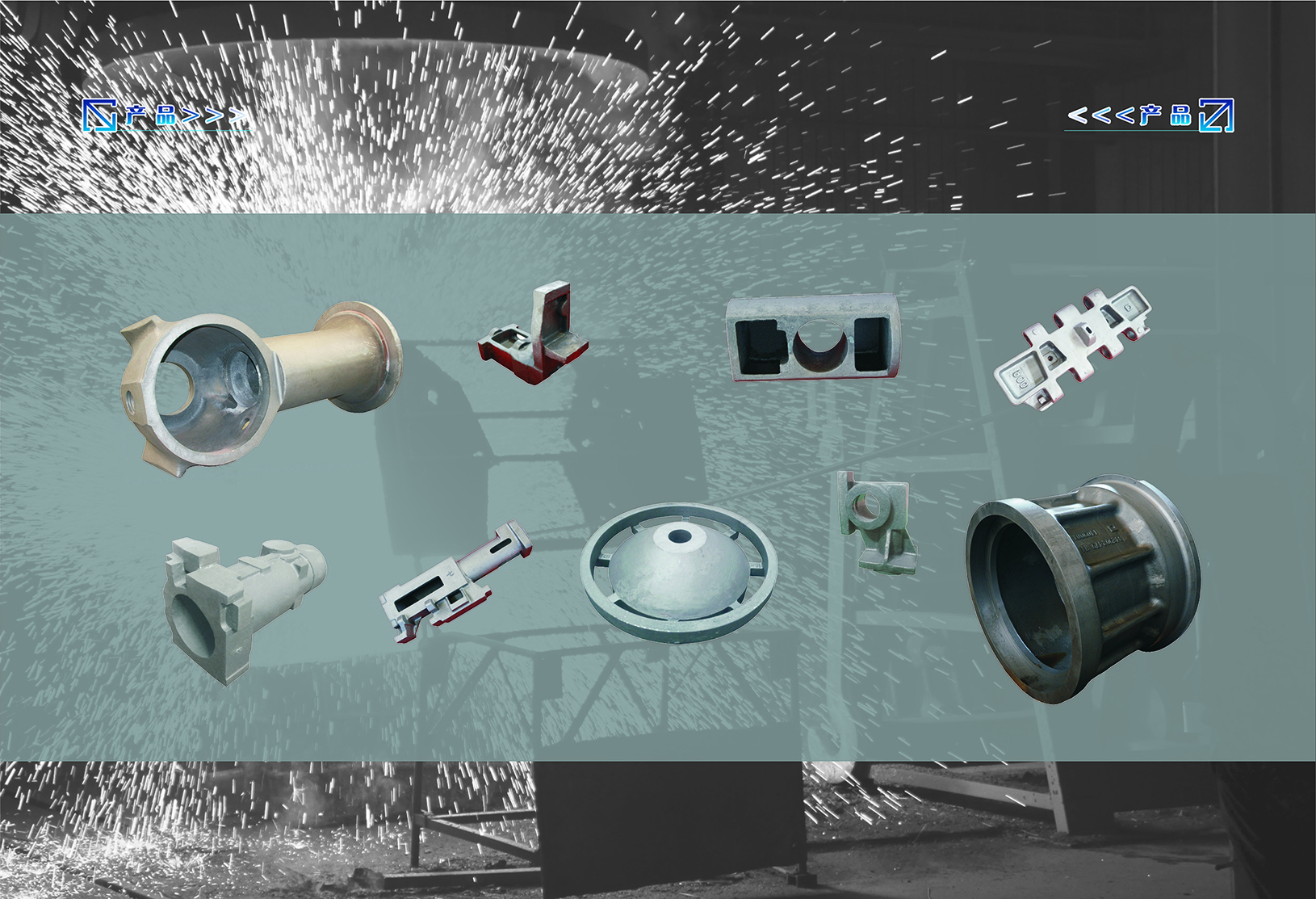

In the construction and infrastructure sectors, the production of concrete pipes is pivotal for various applications, including drainage, sewer systems, and water supply. One of the most critical components in the manufacturing process of these pipes is the mould used to shape them. Stamping concrete pipe mould pallet factories play a significant role in ensuring that the moulds are produced with precision and efficiency. This article explores the importance of these factories in the competitive landscape of concrete pipe manufacturing.

The primary function of concrete pipe mould pallets is to create the desired shape and dimensions of the pipes. These moulds are typically made from high-quality steel or other durable materials, designed to withstand the pressures and stresses involved in the concrete pouring and curing process. Stamping the moulds not only allows for intricate designs and specifications but also enhances the durability and overall quality of the final product.

One of the key advantages of utilizing stamping techniques in mould production is the high level of accuracy achieved. Traditional methods of mould creation may involve manual labour and may introduce inconsistencies in dimensions. In contrast, stamping machines can produce moulds with tight tolerances, ensuring that every concrete pipe manufactured fits the required standards. This precision is crucial for projects that demand strict adherence to specifications, such as municipal infrastructure projects.

stamping concrete pipe mould pallet factories

Moreover, stamping concrete pipe mould pallets allows for mass production, which is vital in meeting the growing demands of the construction industry. As cities expand and infrastructure needs increase, the ability to produce large quantities of high-quality concrete pipes efficiently can give manufacturers a competitive edge. Factories that specialize in stamping methods can streamline production processes, reducing lead times and helping clients meet project deadlines.

In addition to efficiency and precision, sustainability is another critical aspect of modern manufacturing practices. Many stamping concrete pipe mould pallet factories are now adopting eco-friendly practices in their production processes. This includes using recycled materials for mould production and optimizing energy consumption. By focusing on environmentally friendly manufacturing methods, these factories not only contribute to reducing their carbon footprint but also appeal to clients who prioritize sustainable construction practices.

The innovation in stamping technology is constantly evolving. Advanced computerized systems and automation have greatly enhanced the capabilities of mould production. This technological advancement enables factories to design complex moulds with greater ease, catering to various project requirements. As the construction industry embraces digitalization, stamping concrete pipe mould pallet factories are expected to integrate more sophisticated technologies to stay ahead of the curve.

In conclusion, stamping concrete pipe mould pallet factories are indispensable in the concrete pipe manufacturing sector. They ensure high-quality production, efficiency, and sustainability, all while adapting to the ever-changing demands of the construction industry. As we move forward, the importance of these factories will only continue to grow, making them a vital part of the infrastructure development landscape. The future of construction relies heavily on the quality of materials, and stamping concrete pipe mould pallet factories are at the forefront of delivering just that.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025