- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 04, 2024 12:02 Back to list

Factory for Concrete Pipe Moulds and Pallets with Stamping Technology

The Role of Stamping in the Production of Cement Concrete Pipe Mould Pallets

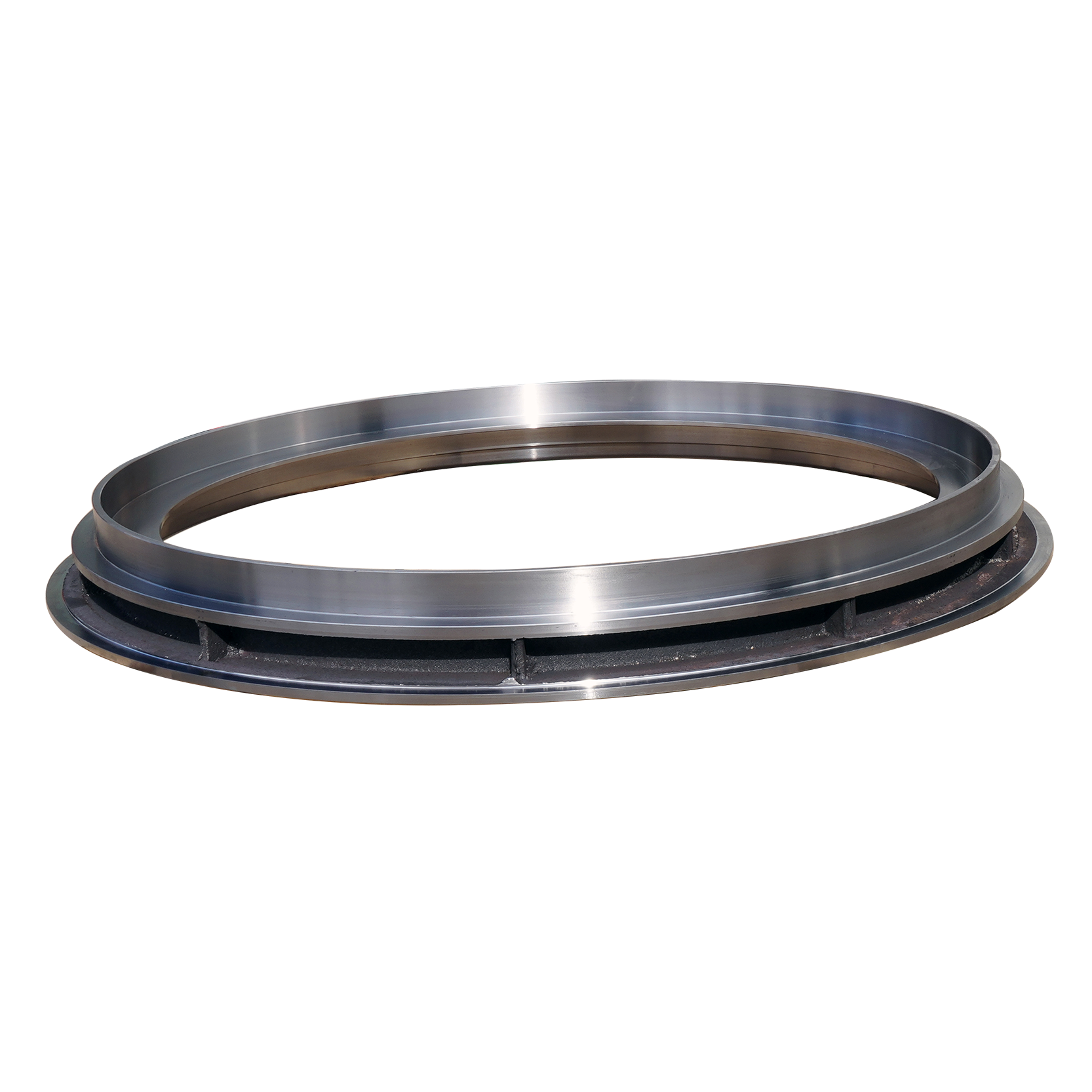

In the world of construction and civil engineering, the demand for durable and reliable infrastructure is ever-increasing. Among the essential components that facilitate such construction are cement concrete pipes, which are widely utilized for drainage, sewage systems, and water supply networks. At the heart of the manufacturing process for these pipes lies the pivotal role of mould pallets, particularly those produced through the stamping process. This article delves into the significance and advantages of stamping in the context of cement concrete pipe mould production.

Understanding Cement Concrete Pipe Moulds

Cement concrete pipe moulds are specialized forms used to shape and cure concrete into pipes. These moulds can vary in size, shape, and capacity depending on the intended use of the concrete pipes. The production of high-quality mould pallets is crucial because they directly affect the efficiency and quality of the pipes produced. Traditional methods of producing moulds often involved labor-intensive, time-consuming processes. However, advances in stamping techniques have revolutionized the industry.

The Stamping Process Explained

Stamping is a manufacturing process that involves the fabrication of parts through the use of a die. This process allows for the efficient and uniform production of various components. In the context of cement concrete pipe moulds, stamping involves pressing sheets of high-strength steel or other materials into specific shapes required for the moulds. This method provides several benefits

1. Precision and Consistency Stamping ensures that each mould pallet is produced with high precision. This reproducibility is crucial for maintaining the quality of the pipes, as inconsistencies in mould dimensions can lead to structural weaknesses in the final product.

2. Increased Production Speed The stamping process significantly reduces the time required to create mould pallets. Where traditional methods might take hours or even days, stamping can produce a large number of moulds in a fraction of the time. This efficiency is particularly important in meeting the high demands of construction projects.

3. Cost-Effectiveness While the initial investment in stamping equipment may be substantial, the long-term savings in labor costs and production times make stamping a cost-effective solution. Manufacturers can achieve higher output without a proportional increase in labor, ultimately reducing per-unit costs.

stamping cement concrete pipe mould pallet factory

4. Material Optimization The stamping process allows for optimal use of materials. Engineers can design moulds that minimize waste, ensuring that the use of raw materials is as efficient as possible. This approach not only reduces costs but also aligns with sustainable manufacturing practices.

Quality Considerations and Advanced Techniques

While the stamping process offers numerous advantages, it is crucial to ensure that the quality of the mould pallets remains high. Manufacturers often employ various quality assurance measures, such as

- Regular Maintenance Stamping equipment requires regular maintenance to ensure that the dies remain sharp and effective, producing high-quality moulds consistently.

- Material Testing The raw materials used in the stamping process should undergo rigorous testing to confirm their strength and durability. High-quality steel alloys are typically preferred for their resistance to wear and corrosion.

- Continuous Innovation The field of stamping technology is continuously evolving. Innovative techniques, such as computer numerical control (CNC) stamping, allow for even greater precision and flexibility in mould design.

Conclusion

The production of cement concrete pipe mould pallets through stamping represents a significant advancement in manufacturing technology within the construction industry. The precision, speed, and cost-effectiveness of stamping not only streamline the production process but also enhance the overall quality of concrete pipes. As the demand for infrastructure continues to grow, the reliance on efficient and reliable manufacturing methods like stamping will undoubtedly increase, positioning it as a cornerstone of modern construction practices. Whether for urban development, road construction, or any other infrastructure projects, the integration of stamping technology into the production of mould pallets ensures that we can meet the challenges of today and tomorrow.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025