- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 13, 2024 16:03 Back to list

steel reinforced concrete pipe mould bottom ring exporters

Exploring the Market for Steel Reinforced Concrete Pipe Mould Bottom Rings

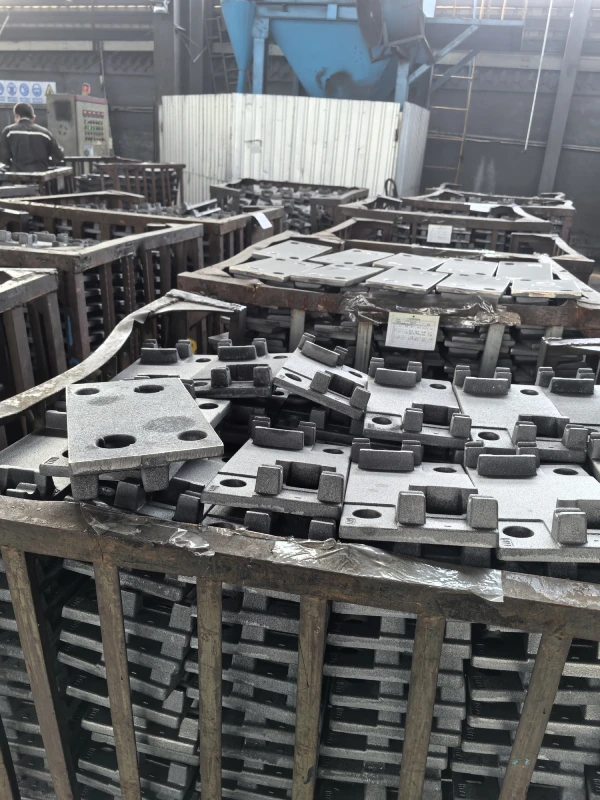

Steel reinforced concrete pipes are widely recognized for their strength, durability, and versatility in various construction and civil engineering applications. One critical component in the production of these pipes is the mould used for their formation. Among the various components of the mould, the bottom ring holds particular significance, serving as the foundational element that shapes and supports the concrete during the curing process. As global demand for steel reinforced concrete pipes increases, the market for mould bottom rings has also witnessed significant growth.

What are Steel Reinforced Concrete Pipe Mould Bottom Rings?

Mould bottom rings are essential parts of the pipe manufacturing process, designed to provide structural integrity and ensure precise dimensions. Constructed using high-quality materials, these rings are often made of steel or have steel reinforcements to withstand the pressure exerted by the wet concrete. Their design can vary depending on the specific requirements of the pipe being produced, including diameter, length, and intended use.

Factors Driving Export Demand

Several factors are driving the export of steel reinforced concrete pipe mould bottom rings

1. Infrastructure Development Many countries are investing heavily in infrastructure projects, such as roads, bridges, and water supply systems. This has led to an increased production of concrete pipes, subsequently boosting the demand for high-quality mould components, including bottom rings.

steel reinforced concrete pipe mould bottom ring exporters

2. Quality and Efficiency Manufacturers are increasingly seeking Mould bottom rings that offer enhanced durability while reducing production costs. High-quality rings help in achieving better finishing and increasing the lifespan of the concrete pipes, making them an attractive option for exporters.

3. Technological Advancements Innovations in manufacturing processes have improved the quality and design of mould bottom rings. This includes advancements in casting techniques and materials, resulting in products that cater to diverse requirements, which, in turn, enhances their export potential.

4. Global Market Reach The growth of global trade and the opening of new markets for construction materials have presented significant opportunities for exporters. Countries that previously depended on local manufacturers are now looking for high-quality products from international suppliers.

Challenges in the Export Market

While the prospects for exporting mould bottom rings appear promising, several challenges remain. Stringent regulations regarding manufacturing standards, transportation logistics, and compliance with international certifications can pose hurdles to exporters. Additionally, competition is intensifying, with numerous manufacturers entering the market, thereby emphasizing the need for innovation and quality assurance.

Conclusion

The export market for steel reinforced concrete pipe mould bottom rings is poised for growth, driven by increasing global infrastructure demands and advancements in manufacturing technology. As the construction industry continues to lean towards durable and efficient materials, manufacturers and exporters must focus on quality, innovation, and compliance to stay competitive. By navigating the challenges and leveraging the opportunities in this expanding market, businesses can establish a robust presence and contribute significantly to the global pipeline infrastructure.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025