- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 14, 2024 06:28 Back to list

Strategies for Effectively Managing Supplier Relationships and Enhancing Supply Chain Performance

Handling Suppliers Best Practices for Effective Supply Chain Management

In today’s fast-paced business environment, effective supplier management has become a cornerstone of successful supply chain operations. Building strong relationships with suppliers not only ensures the seamless flow of goods and services but also enhances innovation, reduces costs, and improves overall efficiency. Here, we explore essential strategies for handling suppliers effectively, providing a roadmap for businesses aiming to optimize their supply chain processes.

1. Establish Clear Communication Channels

Clear and consistent communication is fundamental to successful supplier management. Businesses should establish dedicated points of contact and utilize collaborative tools to facilitate real-time communication. Regular meetings, whether in-person or virtual, can help address concerns and streamline processes. Additionally, leveraging technology such as supply chain management software can help maintain transparency, allowing both parties to keep track of orders, invoices, and performance metrics.

2. Set Performance Metrics

To foster accountability and drive improvement, it’s vital to set clear performance metrics for suppliers. Key Performance Indicators (KPIs) should be established based on quality, delivery times, cost management, and responsiveness. Regularly reviewing these metrics allows businesses to identify areas for improvement, recognize high-performing suppliers, and make informed decisions regarding contract renewals or terminations.

3. Build Strong Relationships

Successful supplier management goes beyond transactional interactions; it requires nurturing partnerships. Building strong relationships can lead to loyalty, better pricing, and early access to new products or innovations. Businesses should take the time to understand their suppliers’ challenges and capabilities, showing empathy and support. Celebrating milestones, recognizing achievements, and fostering a culture of collaboration can significantly enhance these relationships.

4. Diversify the Supplier Base

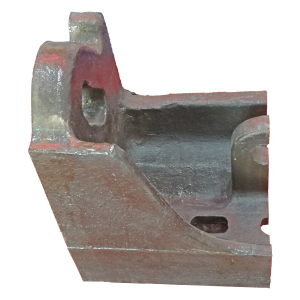

handle suppliers

Relying on a single supplier can be risky; disruptions in their operations can halt your business processes. To mitigate these risks, organizations should strive for a diversified supplier base. By engaging multiple suppliers for critical components, businesses can reduce dependency and ensure continuity in the supply chain. However, it is essential to maintain a balance; managing too many suppliers can complicate logistics and increase operational costs.

5. Invest in Supplier Development

An important aspect of handling suppliers effectively is investing in their development. Providing training, sharing best practices, and collaborating on innovations can uplift the supplier’s capabilities and, in turn, improve the quality of the products or services they provide. Beyond immediate benefits, such investment fosters loyalty and can lead to long-term advantages for both parties.

6. Regularly Evaluate Supplier Performance

Continuous improvement should be at the forefront of supplier management efforts. Regular evaluations of suppliers’ performance based on the predetermined KPIs will help businesses adapt to changing circumstances. Feedback sessions can serve as constructive discussions to understand expectations and address any shortcomings. This proactive approach not only helps maintain high-quality standards but also prepares both parties for future challenges.

7. Implement Risk Management Strategies

Effective supplier handling should also include a risk management strategy. Identifying potential risks, such as financial instability, natural disasters, or geopolitical events, allows businesses to develop contingency plans. This preparation ensures that alternative suppliers are ready to step in if needed, safeguarding operations against unexpected disruptions.

In conclusion, handling suppliers effectively requires a strategic approach centered around communication, relationship-building, and continuous improvement. By implementing these best practices, businesses can create a robust supply chain that not only meets their current demands but also positions them for future growth. In an ever-evolving marketplace, strong supplier relationships become a vital asset that can drive innovation and success.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025