- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 16, 2024 15:56 Back to list

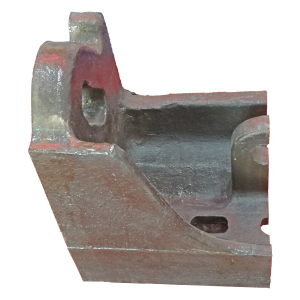

Supplier of Concrete Pipe Molds and Bottom Rings for Cement Casting

The Importance of Quality Molds in Concrete Pipe Production

In the construction and infrastructure industry, concrete and cement products play a pivotal role, particularly when it comes to the manufacturing of pipes. One of the key components in producing high-quality concrete pipes is the mold, specifically the bottom ring mold. This piece of equipment is essential for achieving the desired shape and structural integrity of the pipe. In this article, we will explore the significance of bottom ring molds in the concrete pipe industry and the benefits of sourcing them from a reliable supplier.

Understanding Bottom Ring Molds

The bottom ring mold is a critical component in the production of concrete pipes. It serves as the foundation upon which the rest of the pipe is formed. Typically made from high-strength materials, these molds are designed to withstand the immense pressure of the concrete as it sets. The quality of the mold directly impacts the final product's performance, durability, and longevity. As such, investing in high-quality molds is non-negotiable for manufacturers who wish to produce reliable and sturdy pipes.

The Role of a Supplier

Choosing the right supplier for concrete pipe molds can significantly influence the overall success of a manufacturing operation. A reputable mold supplier should not only provide molds that meet industry standards but also offer customization options. This is particularly essential as different projects may require pipes of various sizes and specifications.

When considering a mold supplier, manufacturers should assess their experience in the industry, the materials used in the molds, and their ability to provide after-sales support. A supplier that offers comprehensive guidance, maintenance, and quick replacement options can save considerable time and costs in the long run.

Benefits of Quality Molds

concrete/cement pipe mold/mould bottom ring supplier

1. Enhanced Product Quality High-quality bottom ring molds ensure that concrete pipes are produced with uniformity in shape and size. This leads to fewer defects and wastage, thus enhancing overall product quality.

2. Improved Efficiency Reliable molds reduce production downtime. When molds are made from durable materials, they last longer and require less frequent replacement. This increases machine uptime and boosts production efficiency.

3. Cost-Effective Production While high-quality molds may come with a higher initial investment, they pay off in the long run by reducing maintenance costs and production errors. Manufacturers can achieve better margins through fewer defective products and less rework.

4. Customization Capabilities A good supplier will work closely with manufacturers to provide molds tailored to specific project requirements. This flexibility can help companies adapt to changing market demands and enhance their competitive edge.

Conclusion

The importance of sourcing high-quality bottom ring molds cannot be overstated in the concrete pipe production industry. The right mold affects not only the shape and integrity of the pipes but also contributes to the overall efficiency and profitability of the manufacturing process.

When selecting a mold supplier, manufacturers must consider factors such as quality, customization options, and after-sales support. By investing in superior molds and partnering with reputable suppliers, manufacturers can ensure that their pipes meet the highest standards and fulfill the rigorous demands of modern infrastructure projects. Ultimately, the bottom ring mold is not just a piece of equipment; it is a crucial factor that can determine the success and reputation of a concrete pipe manufacturer.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025