- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 27, 2024 21:21 Back to list

Supplier of FRC Concrete Pipe Molds for Bottom Rings and Related Accessories in Construction Industry

FRC Concrete Pipe Mold Bottom Ring Supplier Ensuring Quality and Precision in Infrastructure

In the construction and infrastructure development sectors, the importance of reliable materials cannot be overstated. Among the crucial components used in constructing drainage and sewage systems are concrete pipes, which necessitate high-quality molds for production. The bottom ring mold, particularly in Fiber Reinforced Concrete (FRC) applications, plays a pivotal role in ensuring the structural integrity and durability of these pipes. This article delves into the significance of FRC concrete pipe mold bottom ring suppliers, focusing on their contributions to enhanced construction practices.

The Rise of Fiber Reinforced Concrete

FRC has gained popularity owing to its superior mechanical properties compared to conventional concrete. By incorporating fibrous materials into the mix, FRC exhibits increased resistance to cracking, improved ductility, and enhanced tensile strength. This makes it an ideal solution for constructing pipeline systems that must withstand harsh environmental conditions and heavy loads over time. The manufacturing of FRC pipes calls for precise molds, and this is where specialized suppliers come into play.

Understanding the Role of Bottom Ring Molds

The bottom ring mold is essential in shaping the base of concrete pipes. Its design directly impacts the pipe's performance and longevity. A well-constructed bottom ring helps achieve uniform thickness, ensuring that the pipe can endure varying pressure levels once installed. Suppliers of FRC concrete pipe mold bottom rings must have a deep understanding of the engineering requirements to produce molds that meet industry standards.

These molds are typically tailored to specific project needs, considering factors such as pipe diameter, wall thickness, and load-bearing requirements

. Suppliers who can provide bespoke solutions offer significant advantages, as they can cater to unique project specifications, which is crucial for achieving optimal results.Quality and Precision in Manufacturing

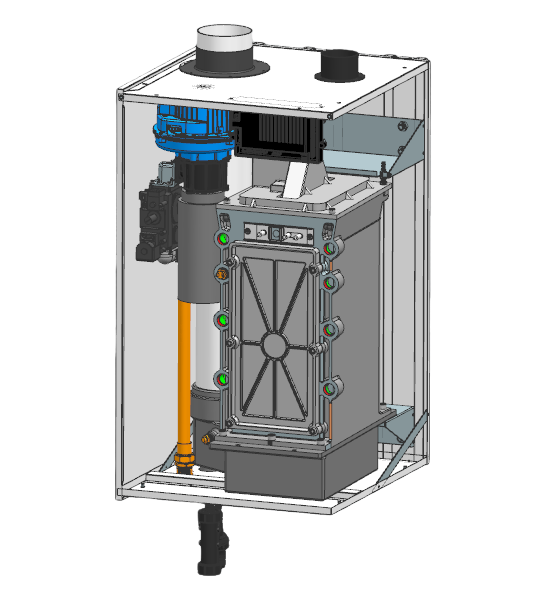

frc concrete pipe mold bottom ring supplier

When selecting a supplier for FRC concrete pipe mold bottom rings, quality should be the priority. The reliability of concrete pipes is heavily dependent on the precision and durability of the molds used during manufacturing. High a quality supplier will employ advanced technologies and adhere to strict quality control standards that ensure each mold produced meets or exceeds industry expectations.

Moreover, suppliers usually utilize high-grade materials for mold construction to guarantee longer service life and resistance to wear and tear during the production process. The incorporation of innovative design elements can further enhance mold efficiency, leading to faster production cycles and reduced costs.

Environmental Considerations

As the construction industry increasingly acknowledges its environmental responsibilities, FRC materials are recognized for their lower carbon footprint compared to traditional concrete. Suppliers focusing on sustainability by sourcing eco-friendly materials and utilizing efficient manufacturing processes align with modern construction practices aimed at minimizing environmental impact.

Additionally, the longevity of FRC pipes created from high-quality molds results in reduced maintenance and replacement needs, contributing to more sustainable infrastructure solutions over time.

Conclusion

The importance of FRC concrete pipe mold bottom ring suppliers extends beyond mere production; they are integral to the development of sustainable and enduring infrastructural solutions. By delivering precision-engineered molds, these suppliers play a crucial role in the overall efficiency and resilience of concrete pipe systems. As urbanization and infrastructure demands continue to grow, partnering with a reliable FRC concrete pipe mold bottom ring supplier is essential for achieving high-quality construction outcomes. In an industry where every detail counts, the right supplier makes a significant difference in ensuring the success and longevity of infrastructure projects.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025