- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 07, 2024 02:55 Back to list

Suppliers for Quality Copper Sand Casting Solutions and Services to Meet Your Manufacturing Needs

Copper Sand Casting Suppliers The Backbone of Quality Metalworks

In the manufacturing industry, copper sand casting has emerged as a vital process for producing high-quality metal parts. This technique, which involves pouring molten copper into a sand mold, allows for intricate designs and exceptional durability. With the growing demand for copper components across various industries—such as automotive, electrical, and construction—the role of reliable copper sand casting suppliers becomes increasingly important.

Understanding Copper Sand Casting

Copper sand casting is a process that utilizes the excellent fluidity and thermal conductivity of copper, making it ideal for producing complex shapes. The process begins with creating a mold from a mixture of sand and a binding agent. Once the mold is prepared, molten copper is poured into it. After the metal cools and solidifies, the mold is broken away to reveal the finished product. This method is not only cost-effective for small to medium production runs but also offers the flexibility to create one-off prototypes.

The Importance of Quality Suppliers

Choosing the right copper sand casting supplier is crucial for manufacturers looking to ensure high-quality output. A reputable supplier will have extensive experience and technological expertise in the casting process. They should also adhere to stringent quality control standards to guarantee that the final products meet industry specifications. For example, look for suppliers who utilize modern techniques such as computer-aided design (CAD) and computer-aided manufacturing (CAM) to optimize the casting process and improve precision.

Furthermore, effective communication is key. A reliable supplier should be able to collaborate closely with clients to understand their specific requirements, offer advice on design improvements, and adjust production methods as necessary. This collaborative approach helps to reduce lead times and enhance overall efficiency in the manufacturing process.

Sustainability and Responsible Sourcing

copper sand casting suppliers

In today’s environmentally conscious market, it is essential for copper sand casting suppliers to adopt sustainable practices. This includes using recycled copper, which not only helps reduce waste but also lowers energy consumption during the production process. Suppliers that prioritize sustainability are more likely to appeal to a broad range of clients, particularly those within sectors that emphasize corporate social responsibility.

When partnering with a supplier, it is a good idea to inquire about their sourcing practices. Working with suppliers that ensure responsible mining and production processes not only helps protect the environment but can also enhance a manufacturer's reputation in the marketplace.

Finding the Right Supplier

With numerous copper sand casting suppliers available, it can be challenging to determine which one fits your needs best. Start by conducting thorough research, including reading reviews and case studies to gauge the supplier's reputation. Ask for samples of their previous work to assess quality directly. Additionally, consider their ability to handle your specific production volumes and timelines.

Networking within industry circles can also yield valuable recommendations. Engaging with trade associations or attending industry conferences may provide opportunities to connect with trusted suppliers renowned for their quality and service.

Conclusion

As industries increasingly rely on high-quality copper components, the significance of experienced and reliable copper sand casting suppliers cannot be overstated. These suppliers not only facilitate the production of durable and complex parts but also play an essential role in fostering innovation and sustainability within the manufacturing sector. By carefully selecting a copper sand casting supplier that aligns with your business values and quality standards, you can ensure the success of your manufacturing endeavors in a competitive marketplace.

-

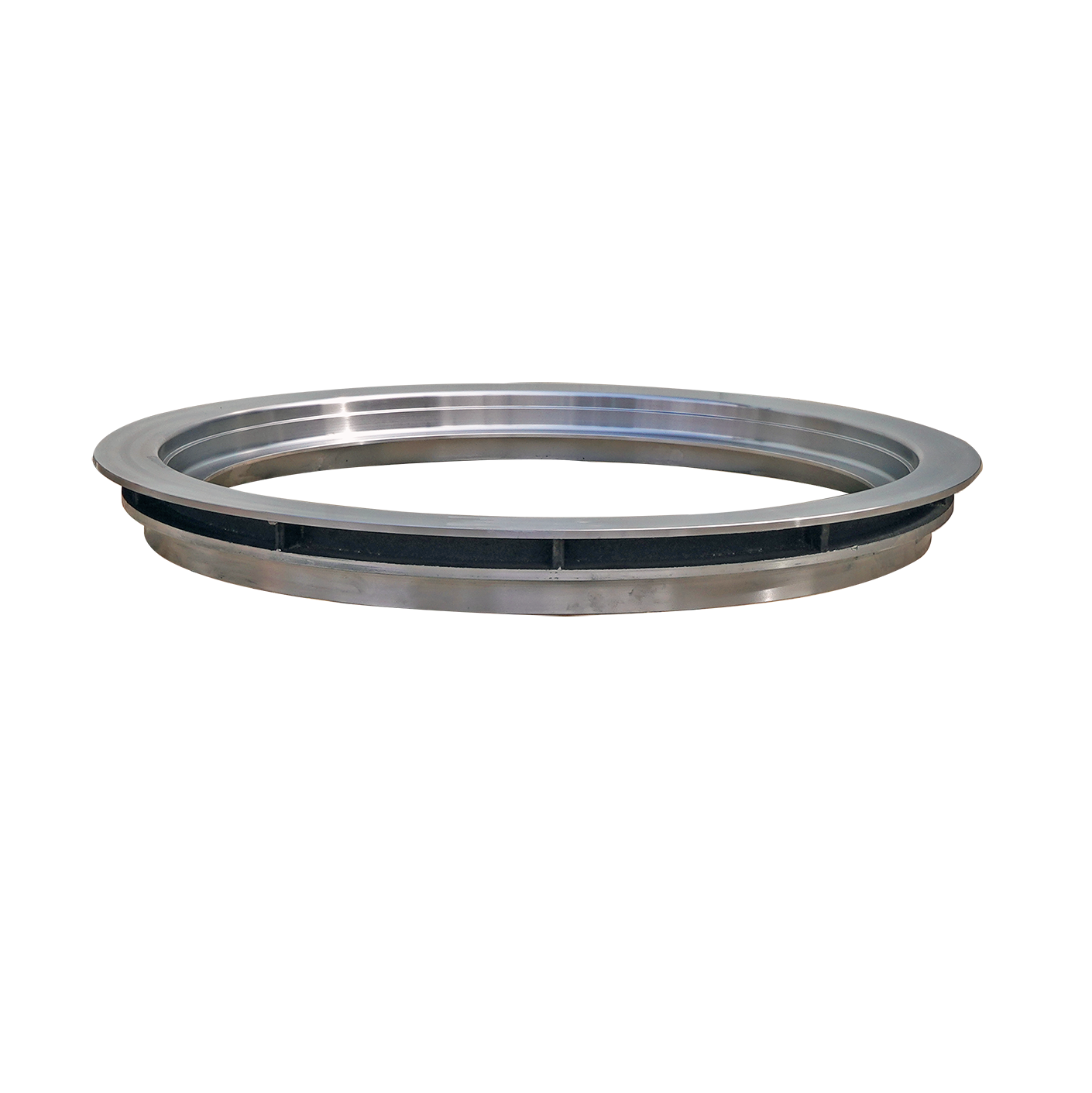

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025