- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aug . 03, 2024 00:38 Back to list

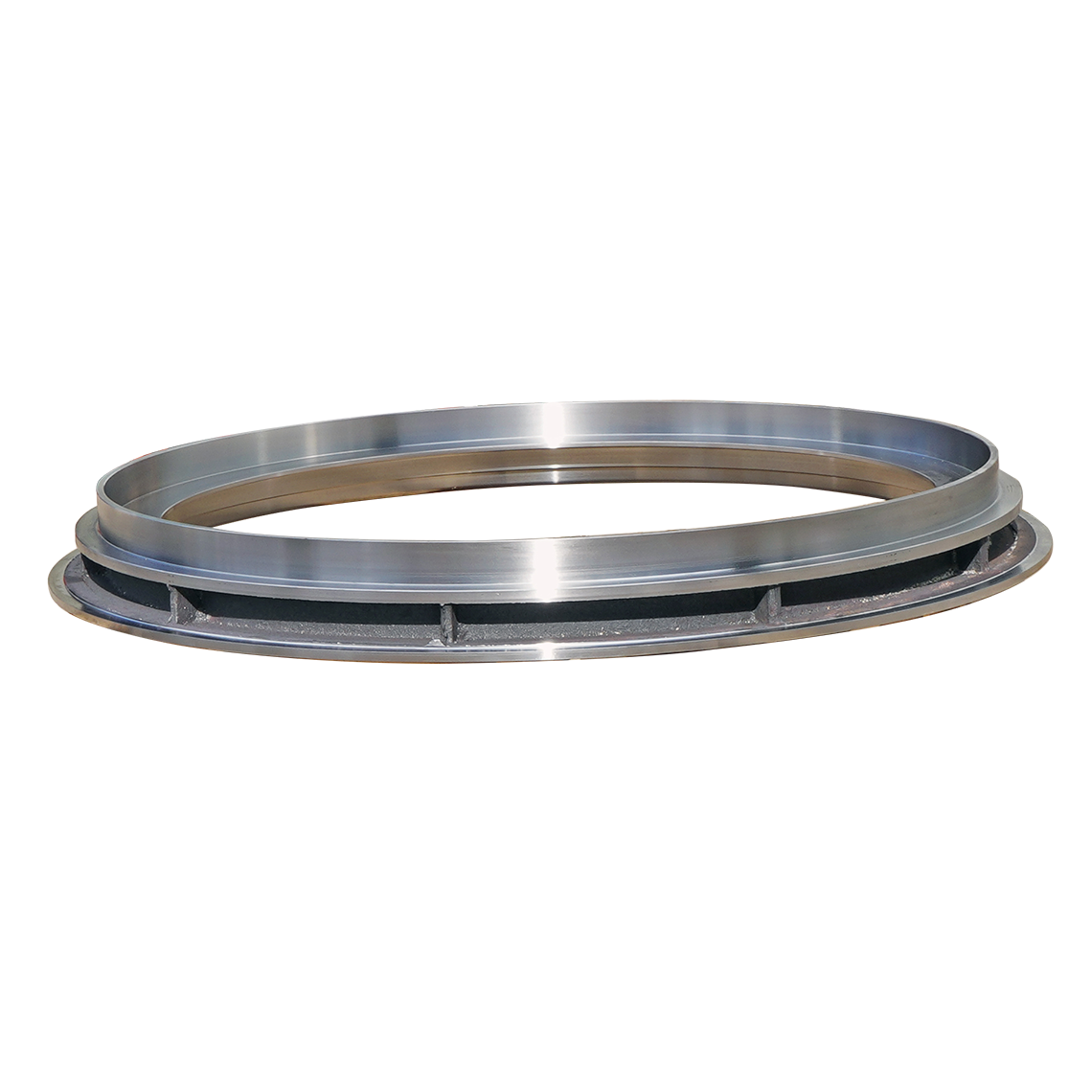

Suppliers of Dry Cast Reinforced Concrete Pipe Mold Bottom Rings for Construction Needs

Dry Cast Reinforced Concrete Pipe Mold Bottom Ring Suppliers

In the realm of civil engineering and infrastructure development, the demand for high-quality materials is paramount. One such essential component is the dry cast reinforced concrete pipe mold bottom ring. These rings are crucial in ensuring the structural integrity and durability of concrete pipes used in various applications, from stormwater management to sewage systems. This article explores the significance of these molds, their suppliers, and the advantages they offer.

Understanding Dry Cast Reinforced Concrete Pipe Molds

Dry cast concrete is a mixture with minimal water content, allowing it to maintain a consistent shape during the mold process. This technology results in denser and stronger concrete pipes with improved load-bearing capacities and resistance to environmental stressors. The bottom ring of the mold plays a vital role in forming the base of the pipe, ensuring uniform thickness and strength throughout the structure.

Suppliers of these molds focus on precision engineering, which is critical for achieving the desired dimensions and specifications. The bottom ring molds are designed to cater to various pipe sizes and are often customizable based on the unique requirements of clients. Reliable suppliers understand that different projects may demand specific material properties and manufacturing techniques, hence their ability to provide tailored solutions.

The Role of Suppliers

Suppliers of dry cast reinforced concrete pipe mold bottom rings play a significant role in modern construction. They not only provide the raw materials needed for manufacturing these molds but also often offer valuable insights and best practices in mold design and usage. Many reputable suppliers invest in research and development to stay ahead of industry trends, ensuring they offer state-of-the-art products.

Moreover, a good supplier emphasizes quality control throughout the production process. They use advanced technologies to test the molds for durability, dimensional accuracy, and overall performance. This standard of excellence ensures that the final concrete pipes meet or exceed industry regulations and client expectations.

dry cast reinfored concrete pipe mold bottom ring suppliers

Advantages of Using Dry Cast Reinforced Concrete Pipe Molds

1. Enhanced Durability Dry cast concrete offers superior strength and durability compared to traditional wet mix concrete. This durability translates into longer-lasting infrastructure, reducing the frequency and cost of repairs or replacements.

2. Cost-Effectiveness While the initial investment in high-quality molds may be higher, the long-term benefits outweigh these costs. The increased lifespan of the pipes and reduced maintenance needs lead to significant savings over time.

3. Environmentally Friendly The dry casting process requires less water, making it a more sustainable option. Additionally, the enhanced lifecycle of the products contributes to reduced environmental impact by lessening the need for frequent replacements.

4. Customizability As infrastructure needs evolve, so do the requirements for concrete pipes. Suppliers who offer customizable molds ensure that contractors can produce pipes suited specifically for their projects, facilitating innovative designs.

5. Faster Production With the efficient design of dry cast molds, manufacturers can achieve faster production cycles. This efficiency is crucial for meeting tight project deadlines.

Conclusion

The importance of dry cast reinforced concrete pipe mold bottom ring suppliers cannot be overstated in the context of modern construction. They provide indispensable products that ensure the durability and reliability of essential infrastructure components. By continuously innovating and maintaining high standards, these suppliers help shape the future of construction, ensuring that projects are executed smoothly and effectively. As cities grow and infrastructure demands increase, the role of these suppliers in delivering quality concrete pipe solutions will continue to be vital.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025