- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 17, 2024 14:36 Back to list

wholesale casting

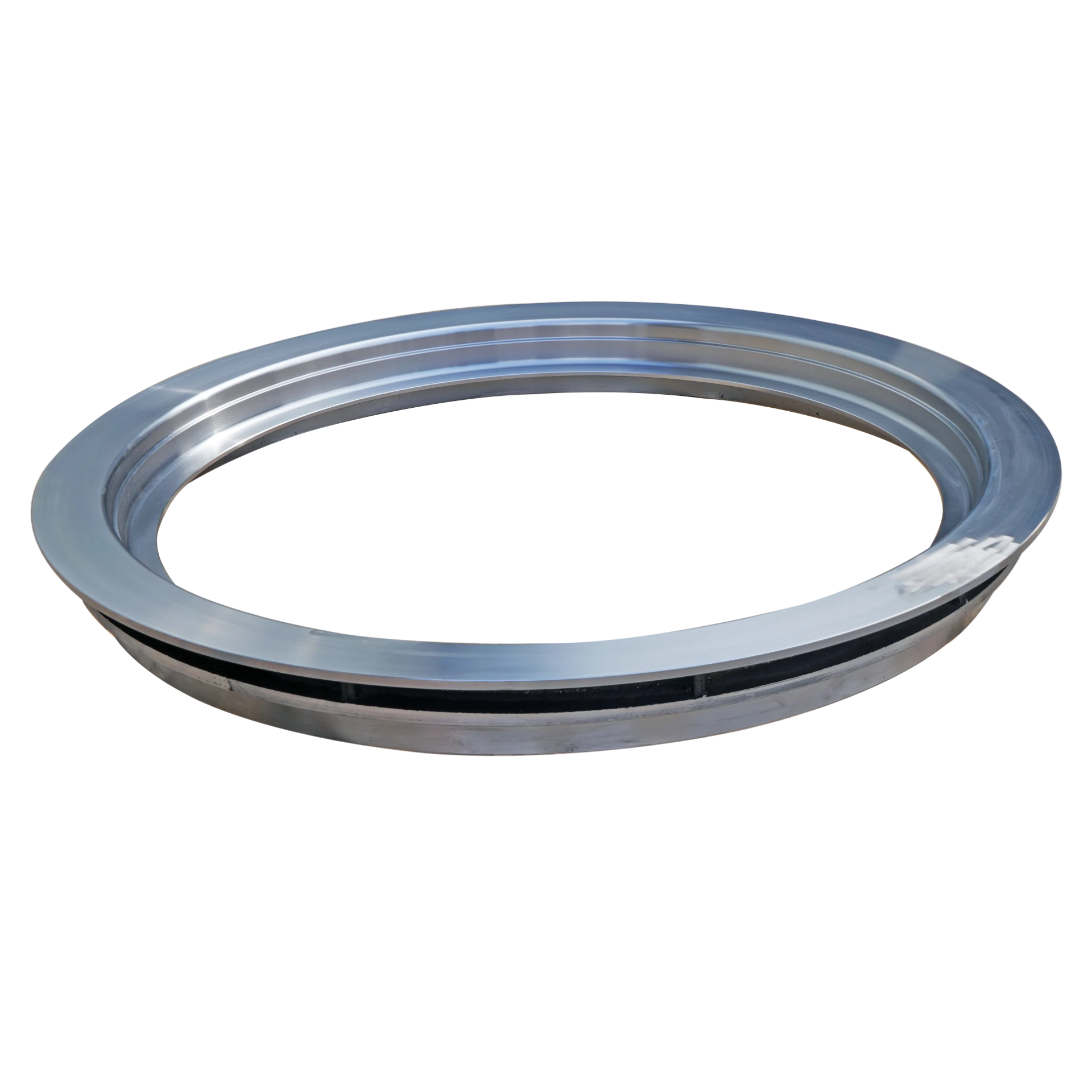

Understanding Wholesale Casting A Comprehensive Overview

In the world of manufacturing and production, wholesale casting plays a pivotal role, providing businesses with a reliable method for creating high-quality metal parts and products at scale. This process involves the pouring of molten metal into molds where it solidifies, taking the shape of the mold. It's a process that dates back thousands of years but remains integral to various industries today, including automotive, aerospace, construction, and consumer goods.

The Basics of Wholesale Casting

At its core, wholesale casting can be defined as the mass production of metal components through the casting process. This approach allows manufacturers to produce large quantities of parts quickly and efficiently, often at a lower cost than other manufacturing methods. The basic steps involved in wholesale casting include pattern making, mold creation, melting the metal, pouring it into the mold, and finally finishing the castings.

1. Pattern Making A pattern is a replica of the final product, usually made from materials like wood, metal, or plastic. Creating a precise pattern is crucial as it directly influences the quality of the final casting.

2. Mold Creation After the pattern is made, molds are created. These can be made from sand, metal, or ceramic, depending on the type of casting process being employed. The choice of mold material affects production speed, surface finish, and the overall cost.

3. Melting the Metal The selected metal undergoes melting in a furnace. The temperature and duration of this process are crucial for ensuring that the metal achieves the desired properties.

4. Pouring Once the metal is molten, it is poured into the mold where it will solidify and take on the shape of the mold. This step requires precision to prevent defects and ensure uniformity.

5. Finishing After the metal has cooled and solidified, the casting is removed from the mold, and any necessary finishing operations—such as machining, sanding, and coating—are performed to meet the specification required by the customer.

Benefits of Wholesale Casting

wholesale casting

Wholesale casting offers several distinct advantages that make it an appealing option for manufacturers

- Cost Efficiency By producing components in large quantities, wholesale casting significantly reduces the cost per unit. This economy of scale is particularly beneficial for businesses looking to lower production costs while maintaining quality.

- Design Flexibility Castings can be produced in a variety of shapes and sizes, offering engineers the flexibility to create complex geometries that may not be achievable with traditional machining methods.

- Material Versatility A wide range of metals can be utilized in the casting process, including aluminum, iron, bronze, and magnesium. This versatility allows manufacturers to choose materials based on the needs of their products.

- Strength and Durability Cast metal products typically exhibit excellent strength and durability, making them suitable for applications where structural integrity is paramount.

Challenges in Wholesale Casting

Despite its many advantages, wholesale casting does come with challenges. The initial costs for patterns and molds can be high, particularly for complex designs. Additionally, the casting process may produce defects such as voids or misalignments if not carefully controlled, necessitating strict quality assurance protocols.

Conclusion

In conclusion, wholesale casting is a vital manufacturing process that continues to evolve alongside technological advancements. With its capability to produce large quantities of complex and durable metal components efficiently and cost-effectively, it remains a cornerstone of modern manufacturing practices. Businesses that recognize and leverage the benefits of wholesale casting can enhance their production capabilities, minimize costs, and meet the growing demands of their industries.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025