- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 04, 2024 20:01 Back to list

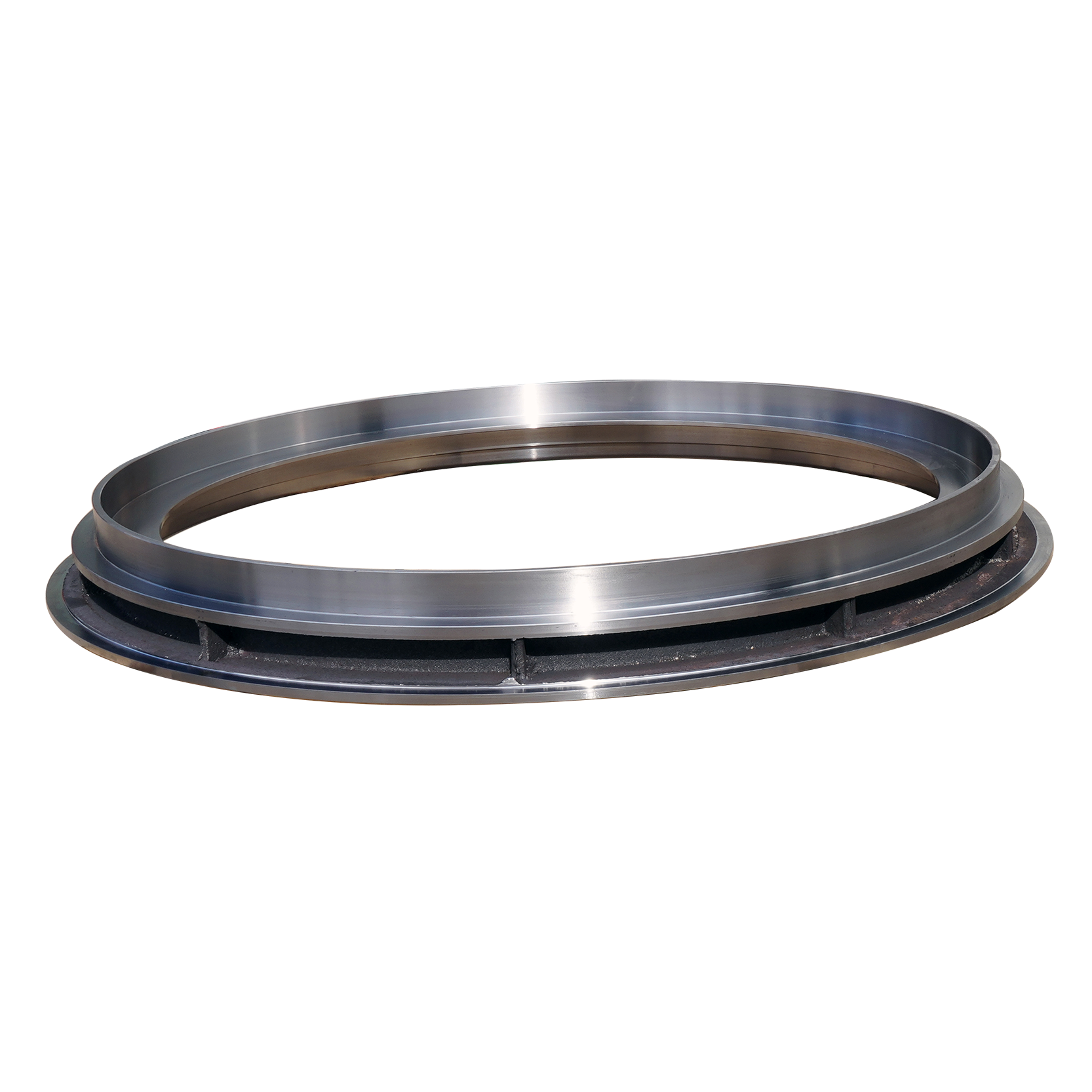

wholesale precision cast rion casting

Understanding Wholesale Precision Cast Iron Casting

In the realm of manufacturing, precision cast iron casting plays a critical role in producing high-quality components across various industries. This technique involves creating intricate shapes and components with exceptional accuracy, making it a favored choice for many applications. This article explores the intricacies and benefits of wholesale precision cast iron casting, showcasing its significance in modern manufacturing.

What is Precision Cast Iron Casting?

Precision cast iron casting is a manufacturing process that utilizes molten iron poured into molds to create components with precise dimensions and specifications. This method is particularly advantageous due to its ability to produce complex geometries and fine details, which traditional casting processes might struggle to achieve. The process begins with creating a wax or polymer pattern, which is then coated with a ceramic material to form a shell. Once the shell hardens, the pattern is melted away, leaving a cavity that is filled with molten cast iron. This technique not only enhances precision but also reduces waste material.

Advantages of Cast Iron

Cast iron has long been revered for its mechanical properties, which include excellent castability, wear resistance, and machinability. Its ability to dampen vibrations makes it an ideal choice for applications in automotive components, machinery, and piping systems. Moreover, cast iron remains ductile under stress, retaining its structural integrity even in demanding conditions.

The precision aspect of cast iron casting allows for tighter tolerances, which can ultimately lead to increased efficiency in the assembly or end-use of the components

. When precision parts are produced with minimal need for additional machining, businesses can save both time and costs associated with production.Wholesale Opportunities in Precision Casting

wholesale precision cast rion casting

For manufacturers and businesses that require large quantities of precision cast iron components, wholesale precision casting provides significant advantages. Purchasing in bulk can lead to reduced costs per piece and enhanced economies of scale. As a result, companies can manage their budgets more effectively while ensuring they meet demand without compromising on quality.

Wholesale suppliers of precision cast iron casting also typically offer a range of services—from design assistance to prototyping and final production. This full-service approach can be particularly beneficial for companies that lack the in-house expertise or resources to develop complex components. By collaborating with experienced suppliers, businesses can leverage advanced technologies in casting, leading to better product outcomes.

Applications of Precision Cast Iron Casting

The applications for precision cast iron casting are vast and diverse. In the automotive sector, precision cast iron components are essential for manufacturing parts such as engine blocks, cylinder heads, and gearbox housings. In construction and infrastructure, cast iron is commonly used for manhole covers, gratings, and pipelines due to its durability and ability to withstand heavy loads.

Moreover, the aerospace and defense industries also benefit from this technique, where precision and quality are paramount. Components that require high strength-to-weight ratios and excellent wear resistance can be produced through precision cast iron casting, ensuring reliability in critical applications.

Conclusion

Wholesale precision cast iron casting exemplifies the intersection of technology, quality, and efficiency in manufacturing. Its ability to deliver intricate components with tight tolerances at scale is invaluable across various industries. As the demand for high-performance components continues to grow, precision cast iron casting will remain a cornerstone of modern manufacturing practices. By choosing reputable wholesale suppliers, businesses can harness the benefits of this innovative technique, leading to enhanced productivity and improved product quality.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025