- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 27, 2024 20:54 Back to list

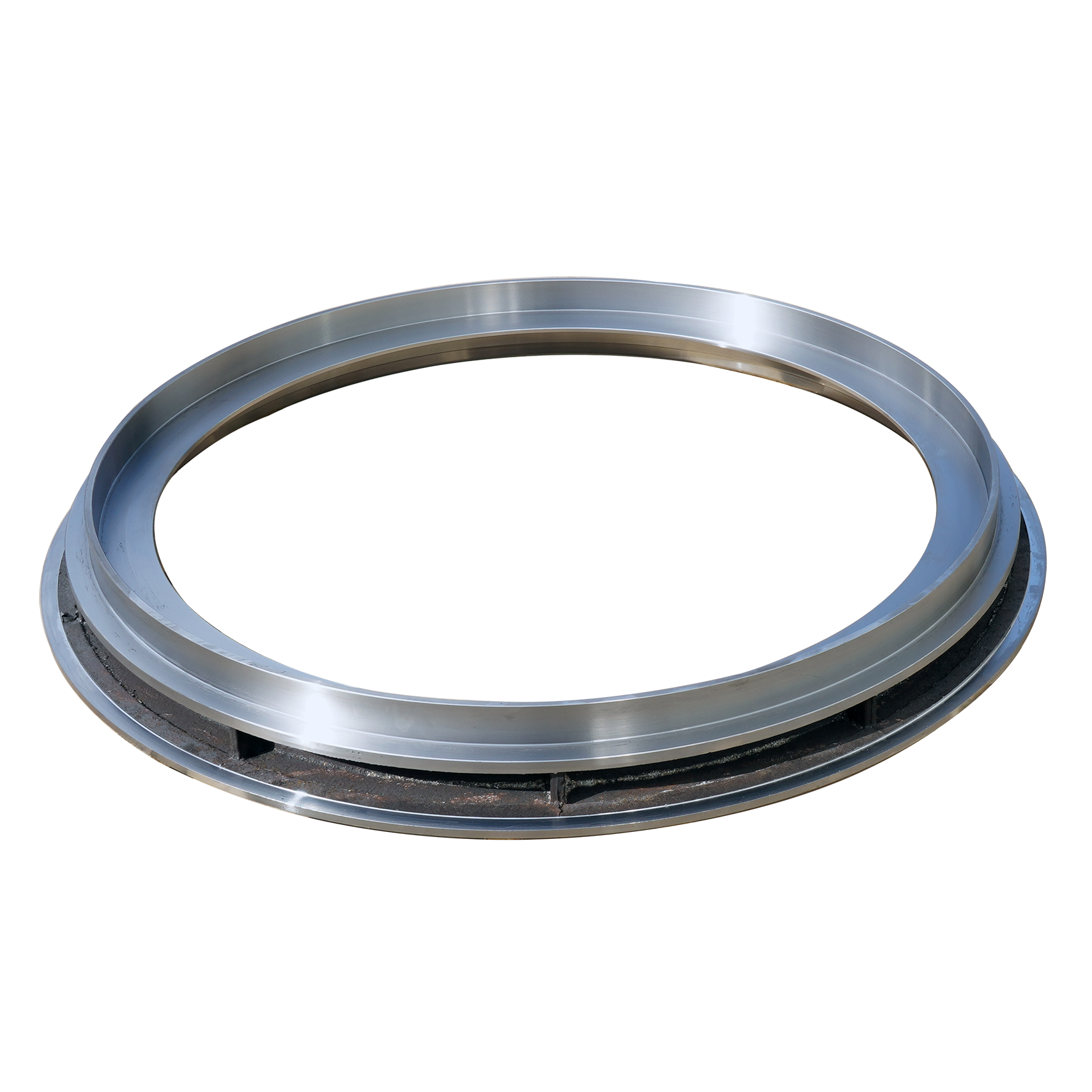

Affordable Bulk Sand Casting Solutions for Your Industrial Needs

Wholesale Sand Casting An In-Depth Overview

Sand casting, also known as sand mold casting, is one of the oldest and most widely used manufacturing processes for creating metal parts. This method is prized for its versatility, ability to create complex shapes, and cost-effectiveness, particularly in bulk production scenarios. In this article, we will explore the wholesale sand casting process, its advantages, applications, and considerations for businesses looking to invest in this technique.

Understanding the Sand Casting Process

The sand casting process involves several essential steps, beginning with the creation of a mold. The mold is formed by compacting sand around a pattern that replicates the desired shape of the final product. This pattern can be made from various materials, including metal, plastic, or wood, and is typically slightly oversized to account for the metal shrinkage that occurs as it cools.

After the mold is prepared, it is then assembled and secured before the molten metal is poured into the cavity. The metal, usually aluminum, iron, or steel, is heated to a liquid state and then carefully poured into the mold. Once the metal has cooled and solidified, the mold is removed, revealing the cast part. The final step involves cleaning and finishing the casting to achieve the desired surface finish and dimensional accuracy.

Advantages of Wholesale Sand Casting

1. Cost-Effectiveness One of the primary advantages of sand casting is its cost-efficiency, particularly for large production runs. The materials used in sand casting—mainly sand, binder, and metal—are relatively inexpensive compared to other manufacturing methods.

2. Complex Geometries Sand casting is capable of producing intricate shapes and designs that might be challenging or impossible to achieve with alternative manufacturing processes. The flexibility of sand molds allows for the creation of complex internal and external features.

3. Variety of Materials This casting technique can accommodate a wide range of metals, allowing manufacturers to select the best material based on the application and required properties of the final product.

4. Scalability Wholesale sand casting is highly scalable, making it suitable for both small and large production volumes. This adaptability is crucial for businesses looking to meet varying market demands.

wholesale sand cast

5. Durability and Strength Products made through sand casting often exhibit excellent mechanical properties, such as durability and strength, due to the solidification process and the ability to use premium alloys.

Applications of Sand Casting

Sand casting is utilized across various industries, including automotive, aerospace, construction, and consumer goods. Common applications include engine blocks, machine bases, pipes, intricate art designs, and many other components where precision and performance are critical.

In the automotive industry, for example, sand casting is often used for producing components such as cylinder heads and engine blocks. In aerospace, it can produce complex parts that must meet strict safety and performance standards. The versatility of sand casting allows manufacturers to cater to diverse markets while maintaining quality.

Considerations for Wholesale Sand Casting

When opting for wholesale sand casting, businesses must consider several factors to ensure a successful partnership with a supplier. One of the most critical aspects is selecting a provider with a track record of quality and reliability. Manufacturers must verify the supplier's certifications, production capabilities, and experience in producing the specific type of castings required.

Additionally, businesses should engage in clear communication regarding production timelines, material specifications, and quality assurance processes to avoid misunderstandings that could lead to delays or defects.

Finally, attention must be paid to post-casting processes, such as machining, surface treatment, and inspection, to ensure that the final products meet all necessary standards and specifications.

Conclusion

In conclusion, wholesale sand casting represents a vital manufacturing process with numerous benefits, particularly for businesses seeking to produce high-quality metal components in large volumes. By understanding the process, advantages, and applications of sand casting, companies can make informed decisions about integrating this technique into their production strategies. As industries continue to evolve and demand for customized solutions increases, sand casting is likely to remain a preferred choice for manufacturers worldwide.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025